Charged spray catalytic micro burner

A micro-combustion and charging technology, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of temperature drop in flame stable area, influence on fuel stability, increase of heat loss, etc., so as to reduce ignition temperature, promote sufficiency and Stability, heat loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments.

[0026] Implementation example

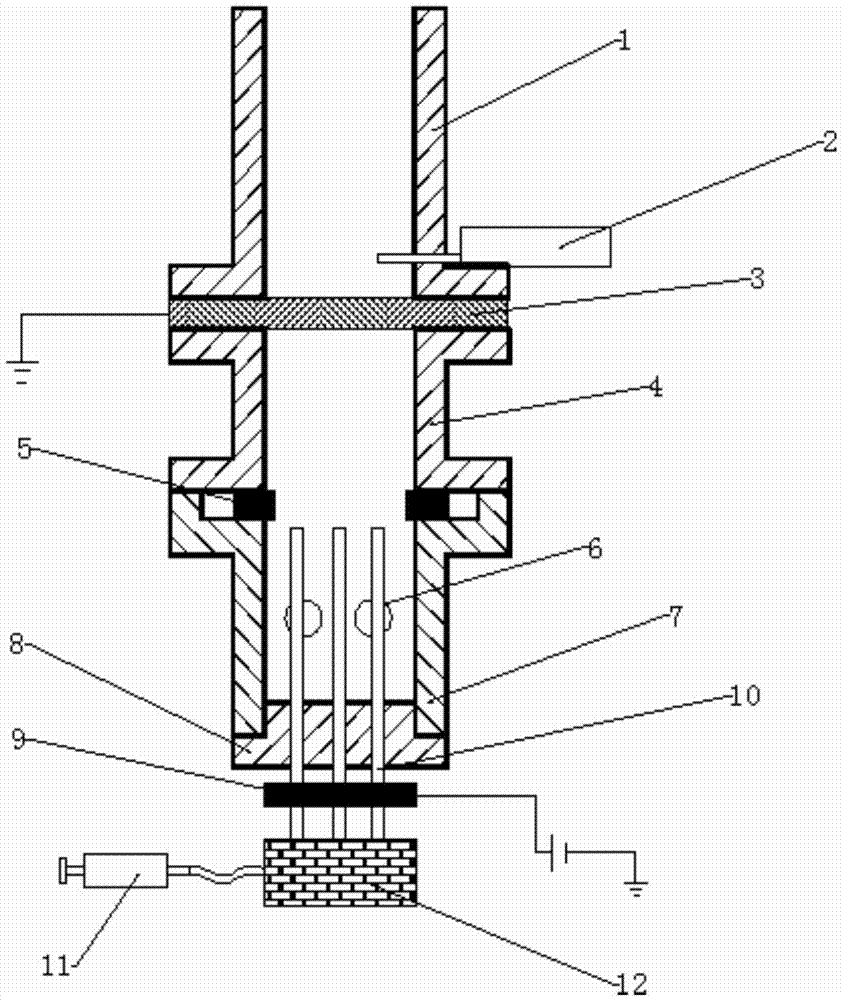

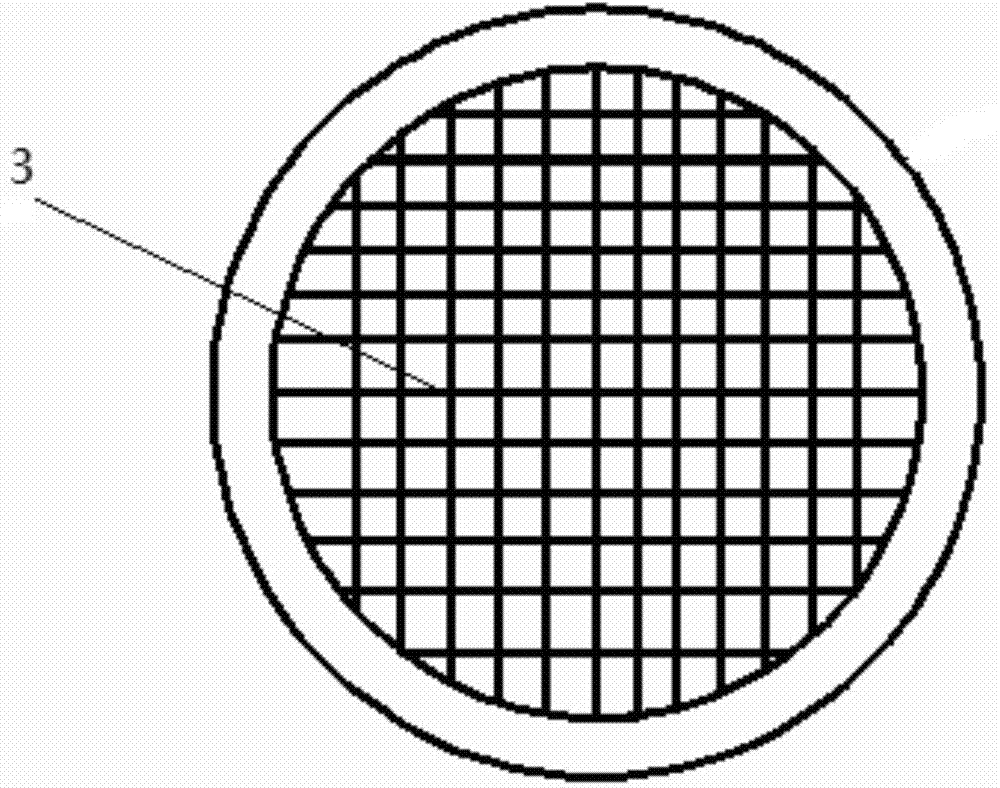

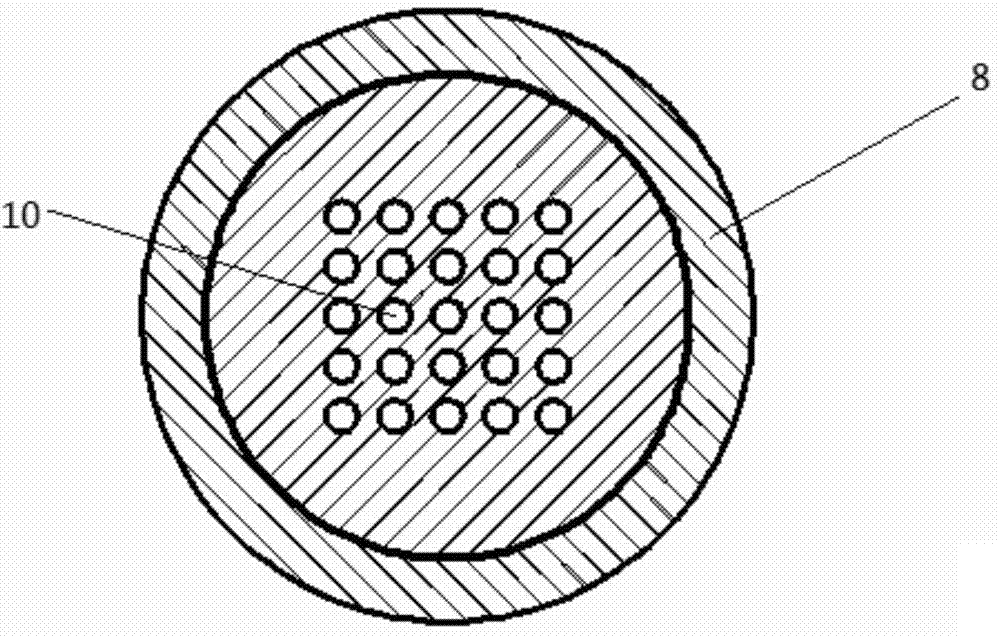

[0027] Such as Figure 1 to Figure 3 shown. The charged spray catalytic micro-combustor of the present invention includes an upper cylinder 1, a middle cylinder 4, a lower cylinder 7, an igniter 2, and a nozzle fixing plug 8, and a grid with a catalyst layer is arranged between the upper cylinder 1 and the middle cylinder 4 3. The ignition needle of the igniter 2 penetrates the wall of the upper cylinder 1 and is placed above the grid in the upper cylinder 1; a ring electrode 5 is set between the middle cylinder 4 and the lower cylinder 7, and a spray nozzle is installed at the outlet of the lower cylinder 7. Pipe fixing plug 8; multiple liquid fuel nozzles 10 are fixed on the nozzle fixing plug 8 .

[0028] The liquid fuel nozzle 10 is connected to the positive pole of a high-voltage DC power supply (the voltage of the DC power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com