Biomass furnace with forced introduction of combustion air

A biomass furnace and air technology, applied in the direction of combustion air/fuel supply, non-flammable liquid/gas transportation, combustion method, etc., can solve the problems of fast heat diffusion, short residence time, high smoke emission, etc., to achieve sufficient Improvement, long burning time, and less ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

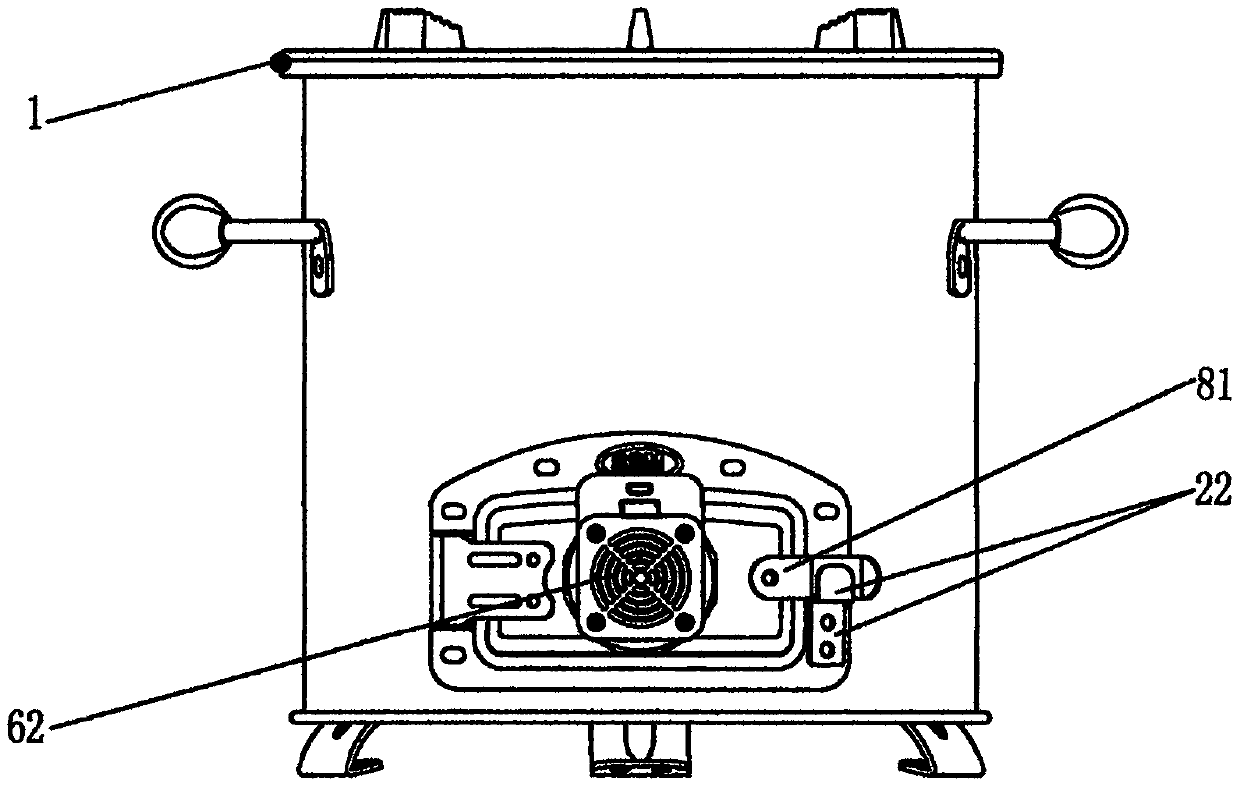

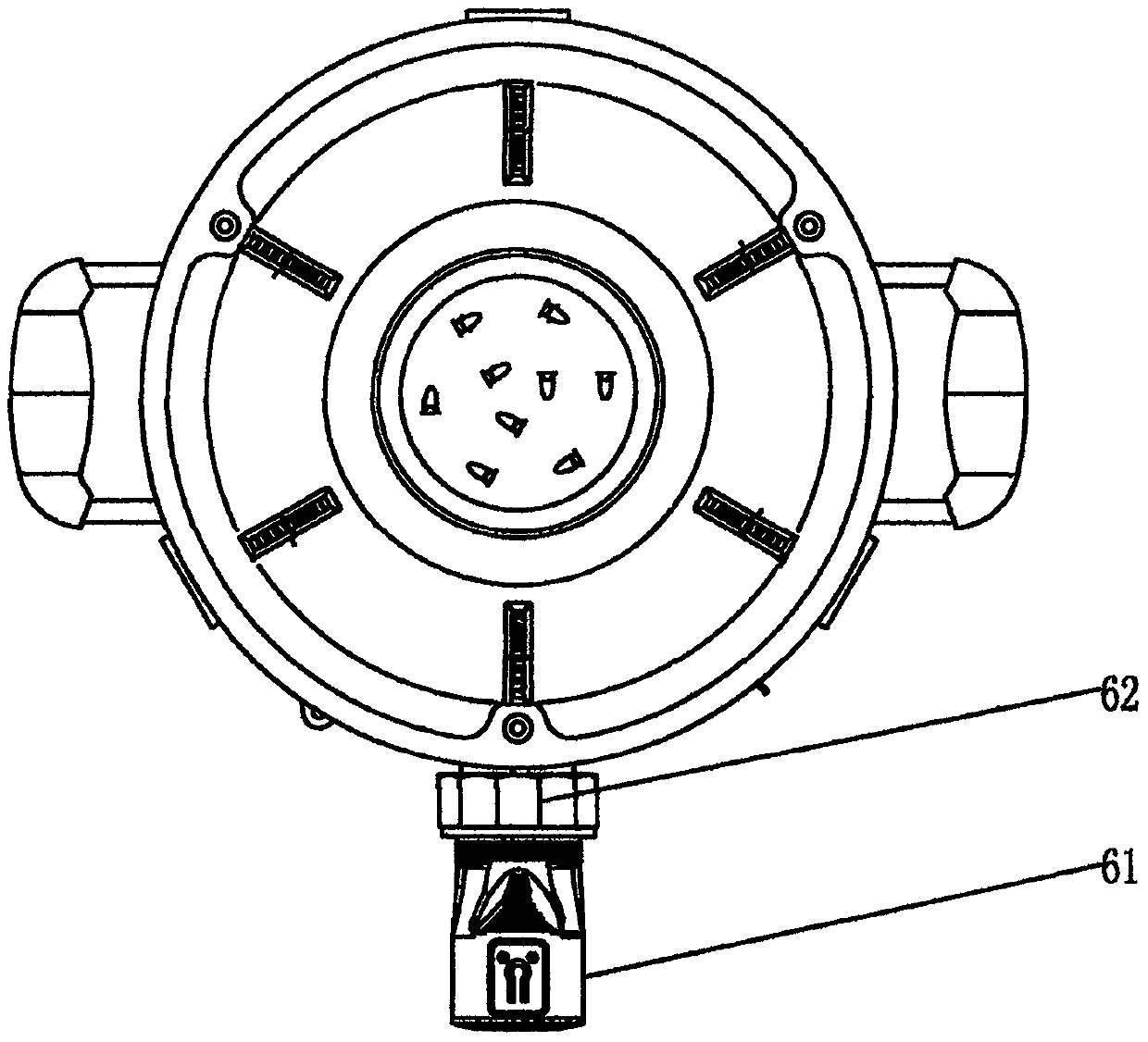

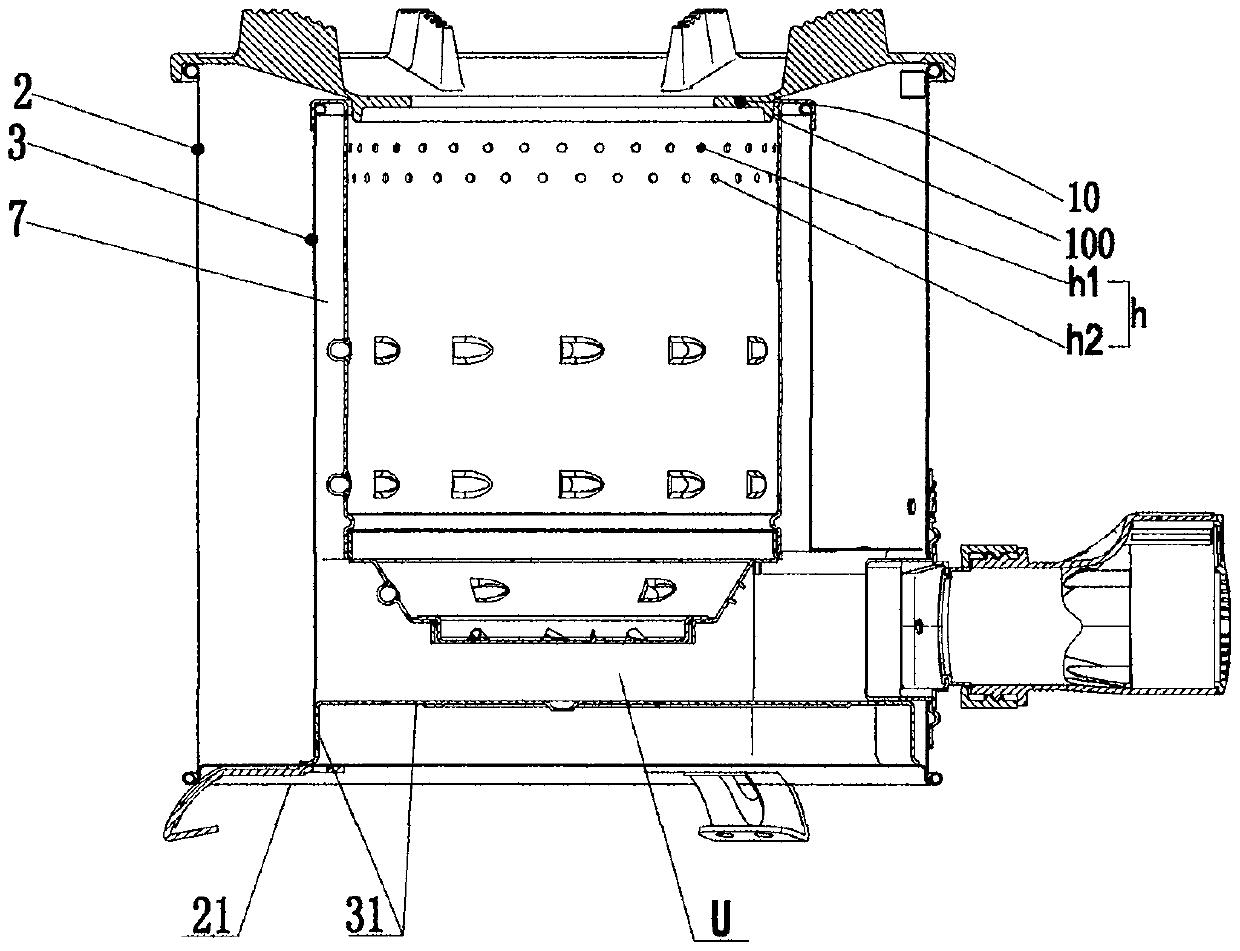

[0031] see Figure 1-5 And as shown in 9-12, the biomass furnace forcibly introducing combustion air includes a furnace panel 1 with a central hole, an outer casing 2 with an opening at the top and a bottom plate 21 at the bottom, an opening at the top and a bottom plate at the bottom 31 of the inner lining tube 3, the furnace panel 1 is fixed on the outer shell 2, the bottom plate 31 of the inner lining tube 3 is placed on the bottom plate 21 of the outer shell 2, and the opening on the side of the inner lining tube 3 and the opening of the inner lining tube 3 Bottom plate 31 is jointly enclosed and formed as ash muzzle U1, and this ash muzzle U1 is engaged with the opening 20 provided on the side wall of outer shell 2, and a combustion tube is installed in the inner liner tube 3, and the combustion tube consists of a straight tube body. 4 and a bowl-shaped bottom 5b, the straight body 4 is covered at the top port of the inner liner 3, and the bowl-shaped bottom 5b is higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com