High-wax thickened oil cross-linked polymer nanometer material pour point depressant and preparation method thereof

A cross-linked polymer and pour point depressant technology, which is applied in the field of polymer nanomaterial preparation, can solve the problem of poor dispersion and thermal stability of the pour point depressant product, unsatisfactory effect of high-wax and high-viscosity crude oil, and inability to ensure effective reaction time In order to achieve the effects of easy mass production, good pour point depressing effect and long acting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

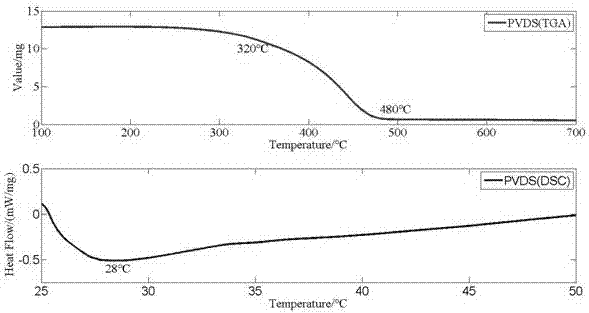

[0032] Example 1: Poly(vinylimidazole-divinylbenzene-octadecyl methacrylate, PVDS)

[0033] (1) Weigh 10g of octadecyl methacrylate, according to the molar ratio of vinylimidazole, divinylbenzene, and octadecyl methacrylate as 1:1:1, in which divinylbenzene is used as a crosslinking agent, add The amount of dispersant (polyvinylpyrrolidone) is 2% of the total mass of the monomer, added to 50 ml of ethanol, protected by nitrogen, added 0.1 g of azobisisobutyronitrile, condensed and refluxed, and reacted at 60 ° C for 4 hours.

[0034] (2) The obtained reaction solution was suction-filtered with a Buchner funnel, washed with alcohol and acetone for 3-4 times, and then vacuum-dried at 25-35°C to obtain poly(vinylimidazole-divinylbenzene-methacrylic acid octadecyl ester) pour point depressant powder.

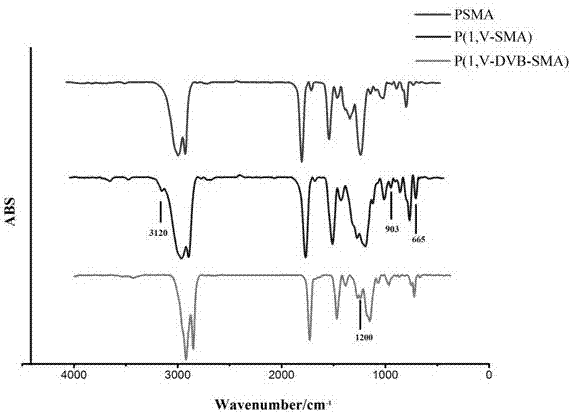

[0035] The infrared spectrum of synthetic poly(vinylimidazole-divinylbenzene-octadecyl methacrylate) is as follows figure 1 As shown, the top is the infrared spectrum of polyoctea...

Embodiment 2

[0049] Example 2: The preparation method of poly(vinylimidazole-divinylbenzene-lauryl methacrylate), the steps are the same as in Example 1, except that octadecyl methacrylate is replaced by lauryl methacrylate.

Embodiment 3

[0050] Example 3: The preparation method of poly(vinylimidazole-divinylbenzene-tetradecyl methacrylate), the steps are the same as in Example 1, except that tetradecyl methacrylate is used instead of octadecyl methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

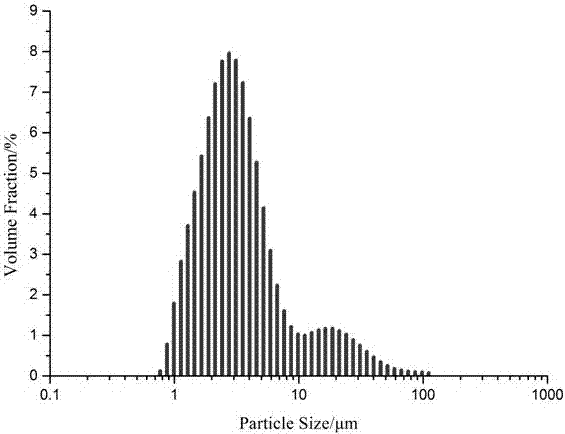

| Particle size | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com