Tail gas treatment device for treating process exhaust gas of LED MOCVD equipment

An exhaust gas treatment and process technology, which is applied in the field of exhaust gas treatment devices to avoid excessively high local combustion temperature, ensure safety, and prevent tempering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

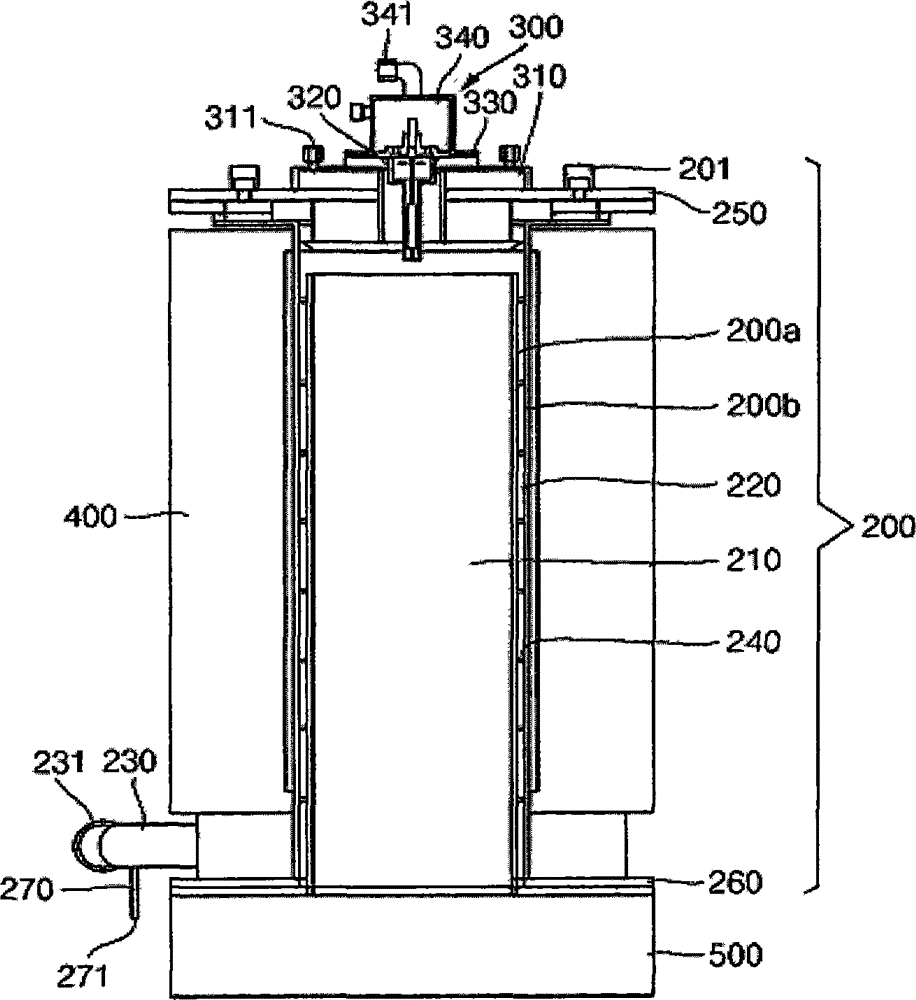

[0048] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

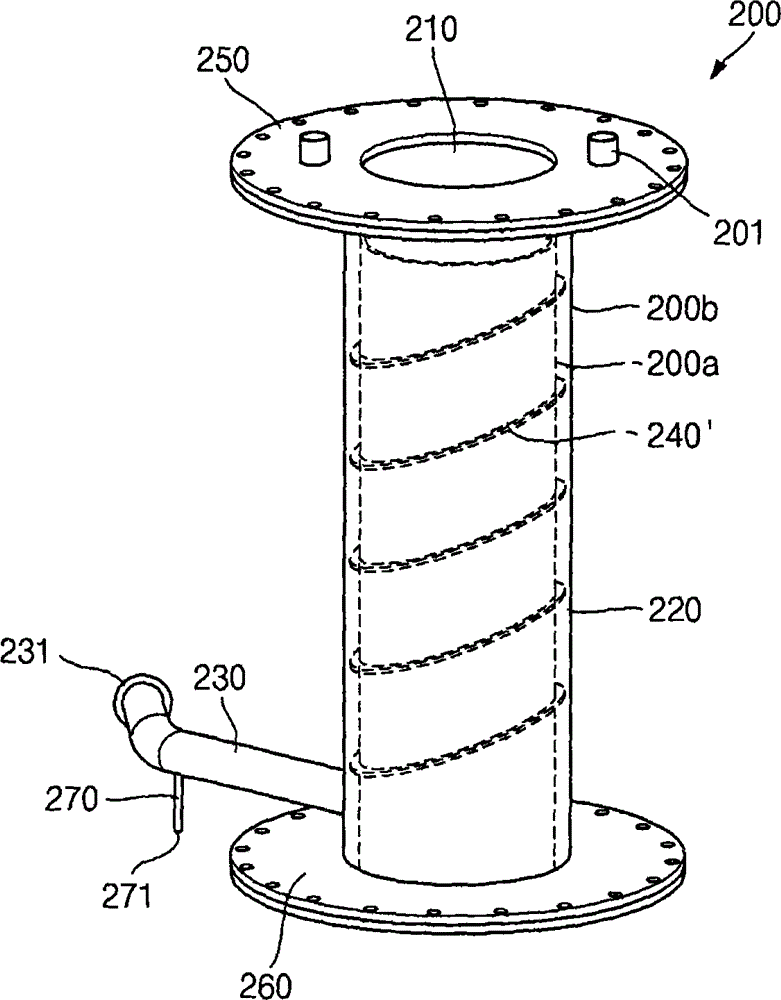

[0049] A tail gas treatment device for treating process waste gas of LEDMOCVD equipment, characterized in that it includes a combustion chamber for burning waste gas and a heating belt wrapping the combustion chamber, and the combustion chamber includes annular nested outer Cavity and inner cavity; the nested outer cavity and inner cavity have a common top end cover, and the end cover locks the outer cavity and inner cavity together through screws and gaskets; the outer wall of the outer cavity is equipped with Two embracing heating bands wrap the entire outer cavity.

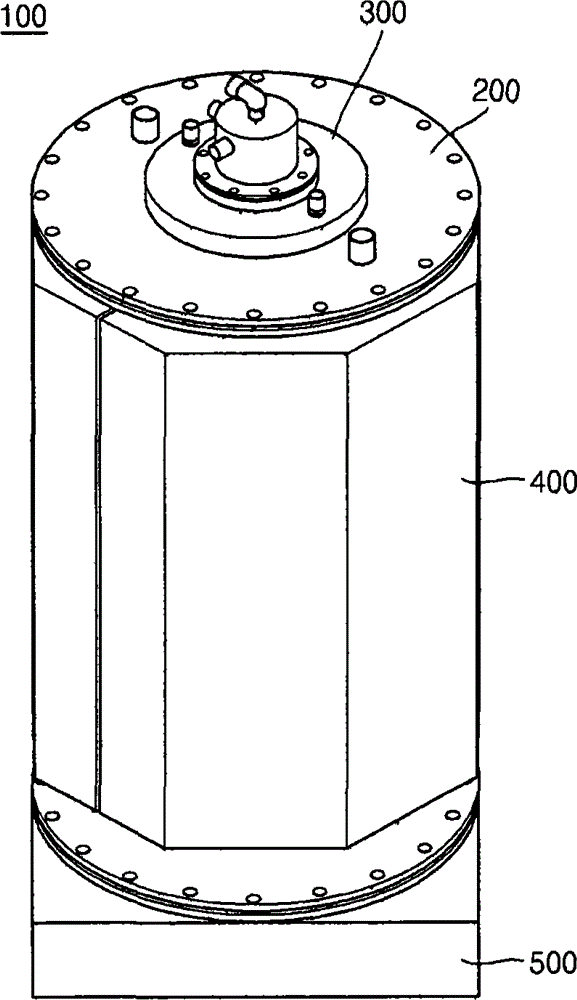

[0050] Such as figure 1 As shown, the present invention 100 comprises a combustion chamber 200 and a heating belt 400 wrapping the combustion chamber, 300 represents the end cover of the combustion chamber 200, and 500 represents a cooling structure connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com