Tooth number variable gear stepless transmission

A technology of continuously variable transmission and variable speed gear, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as limited development prospects, and achieve the effects of simple structure, reduced pollution, and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

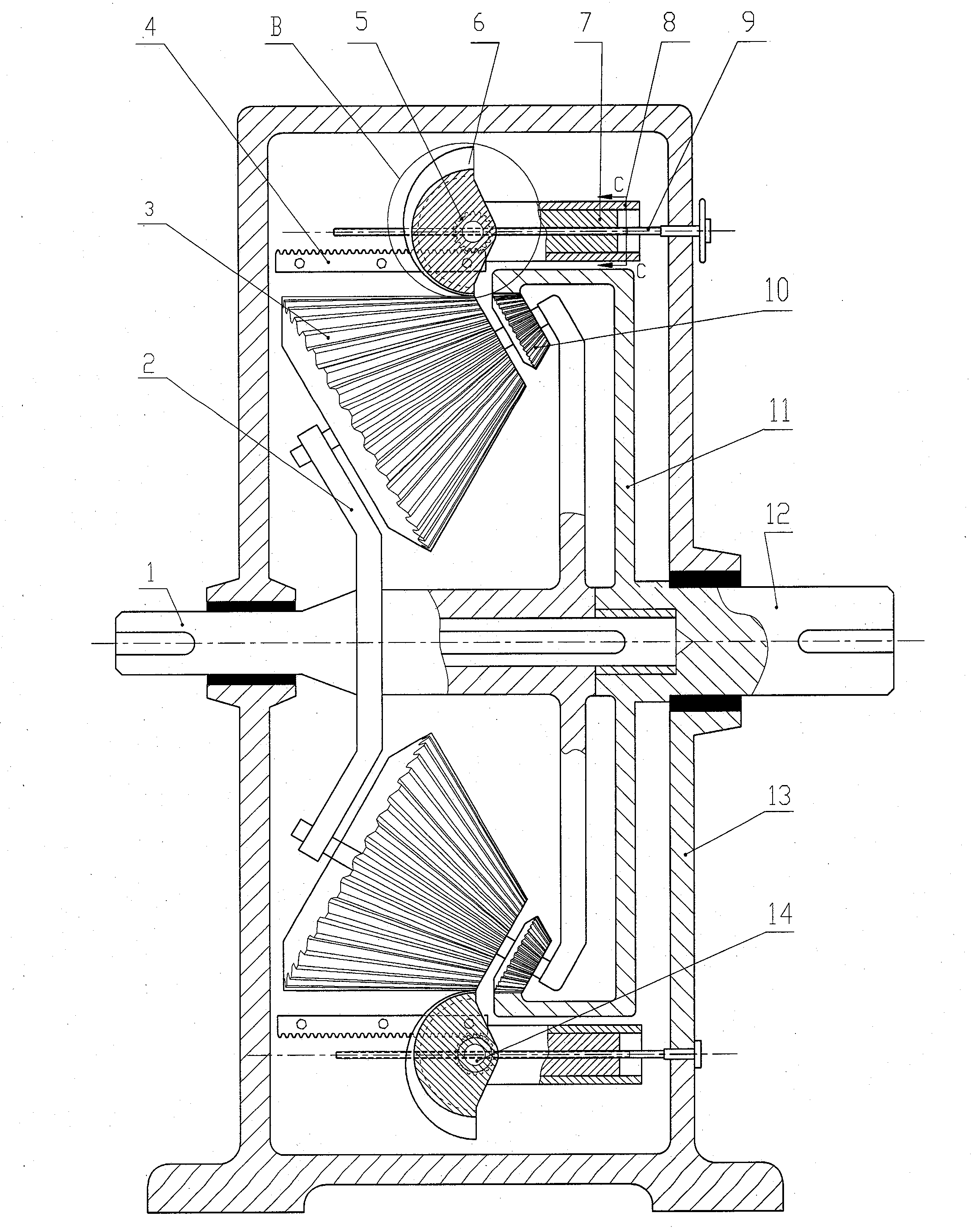

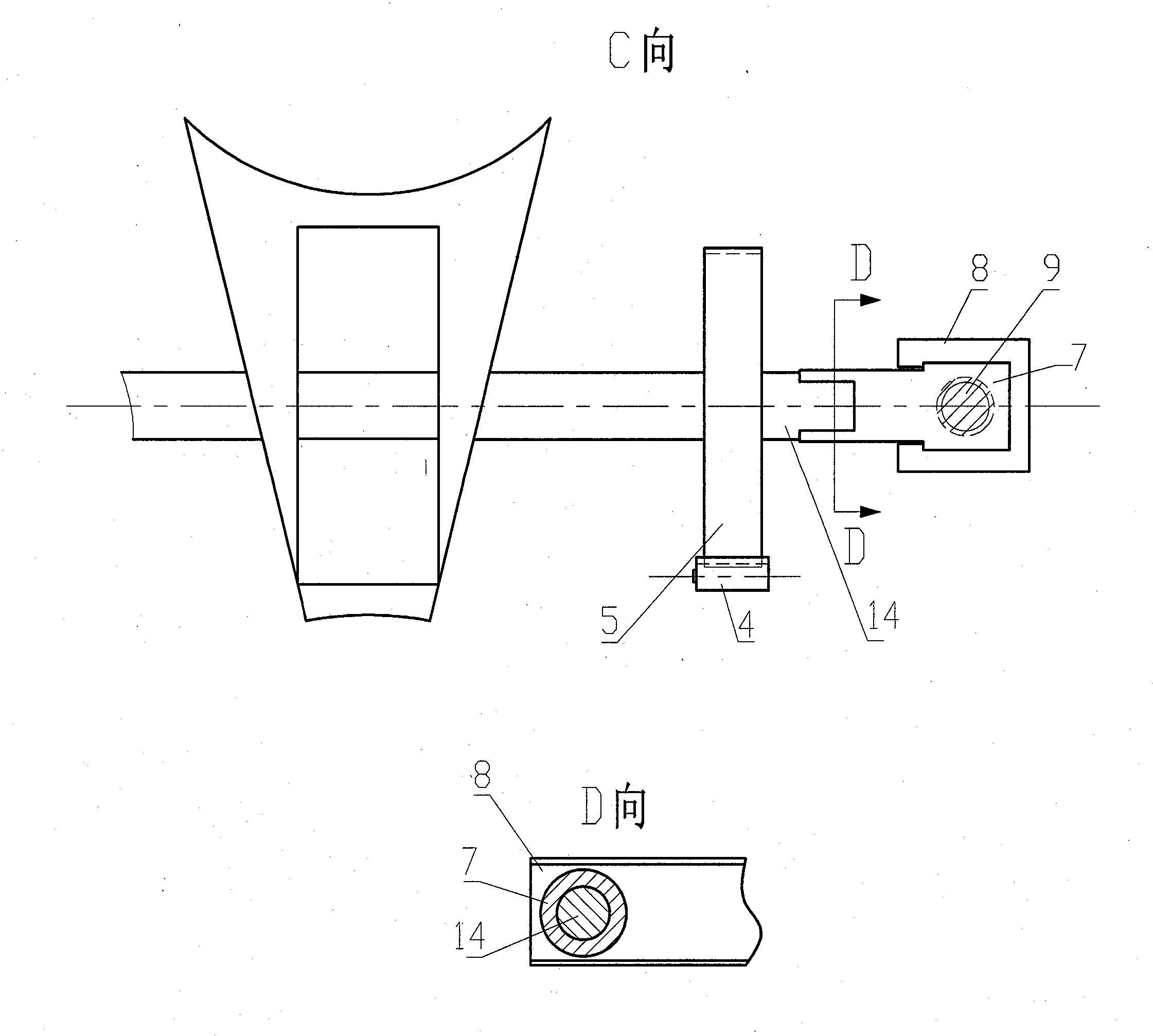

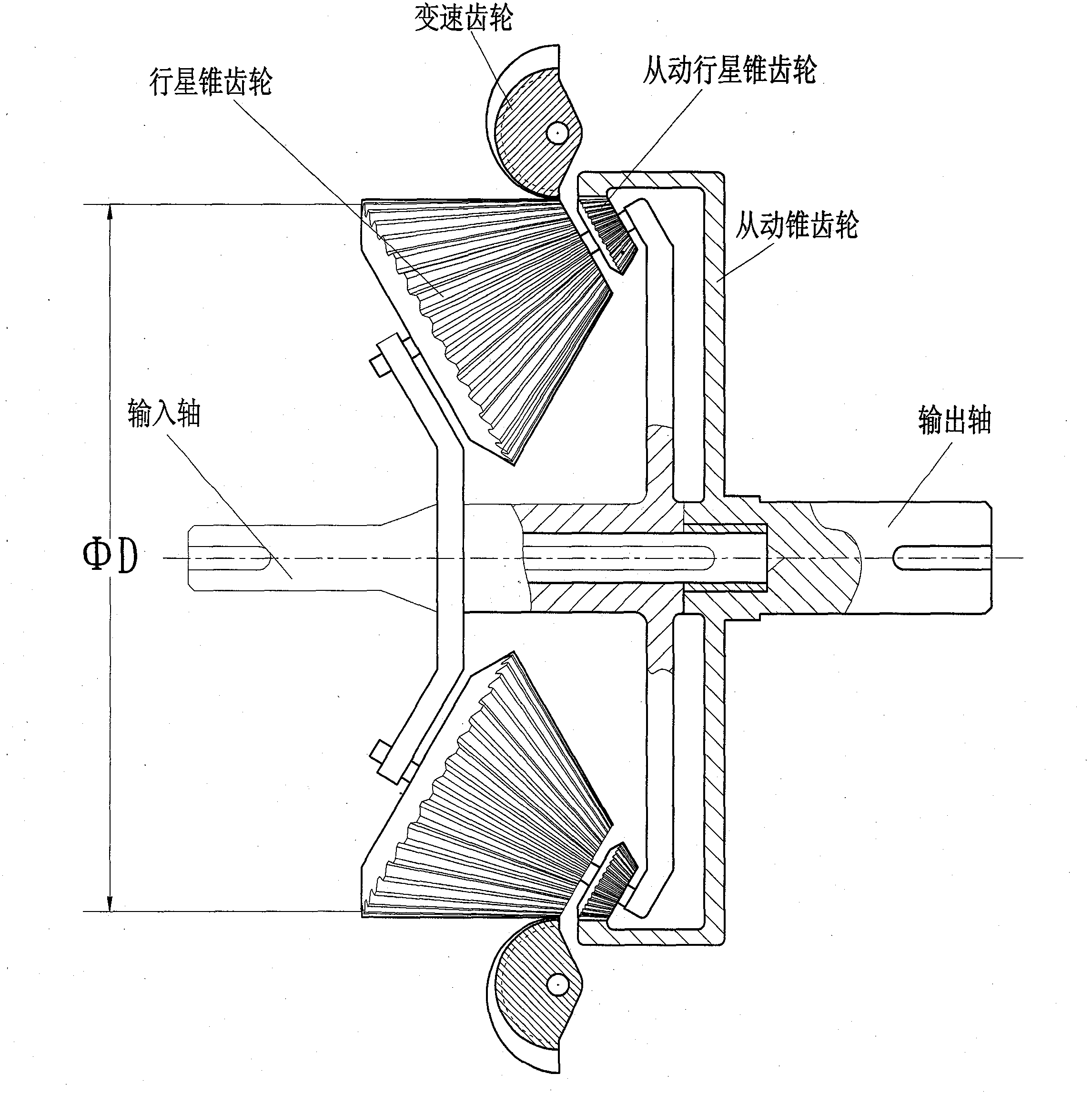

[0017] Such as figure 1 As shown, the present invention is a continuously variable gear with a variable number of teeth. When working, the power that needs to be shifted is connected to the input shaft (1) through a coupling and input, and the input shaft (1) and the cage (2) are fixedly connected to drive the planets. The bevel gear (3) makes each planetary bevel gear (3) revolve around the central axis with the input shaft (1) on the one hand, and at the same time rotate itself around the bisecting axis of the cage. The planetary motion synthesized by the two passes through the planetary cone The gear (3) drives the driven bevel gear (10) to transmit the power to the output shaft; if it is a variable speed vehicle, connect the speed regulating screw and the screw of the handwheel (9) through a certain mechanism to make it conform to ergonomics The principle is to consider the convenience of the driver's operation and to bring out the speed change function of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com