Burnpot for solid particulate stove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

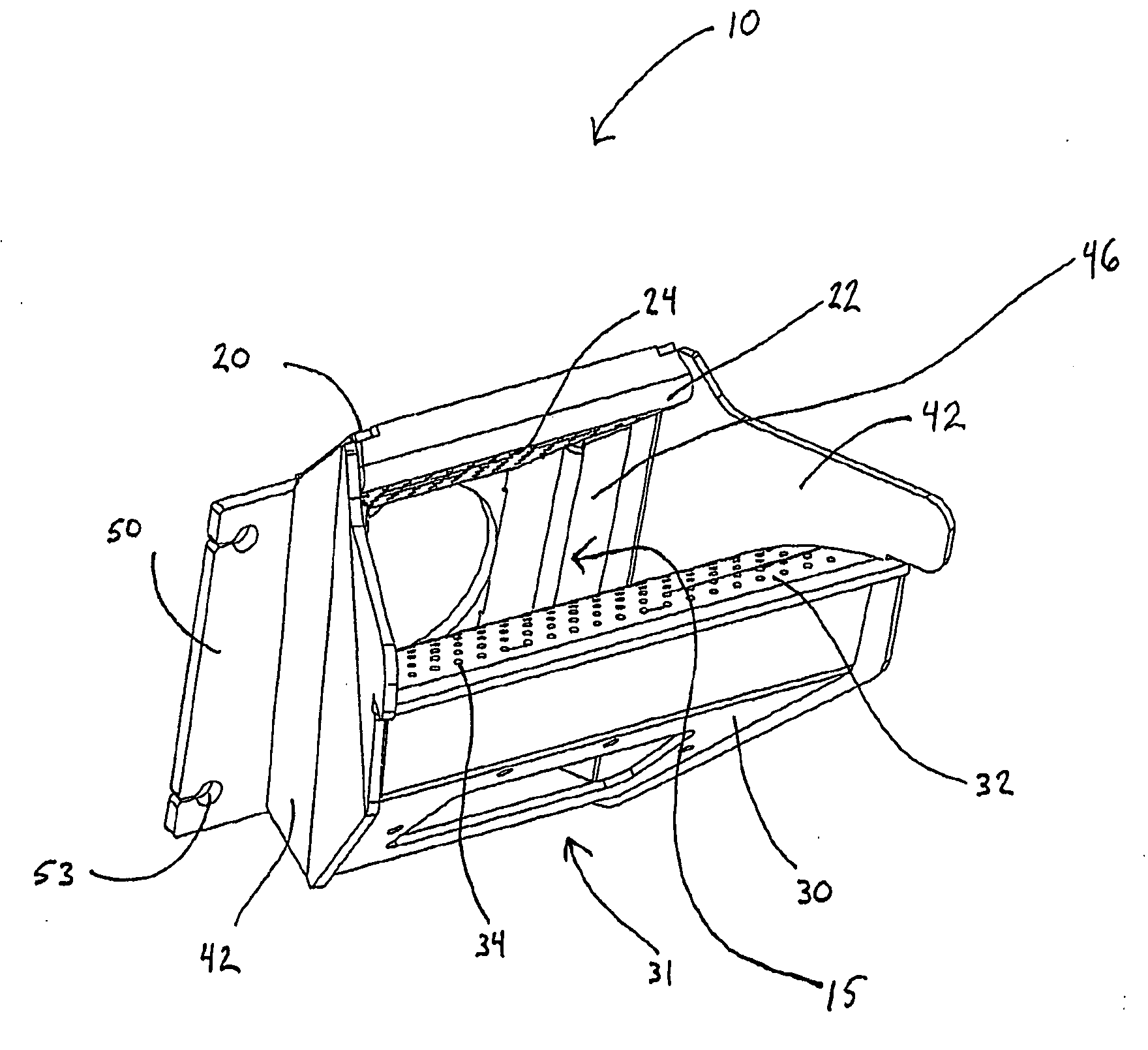

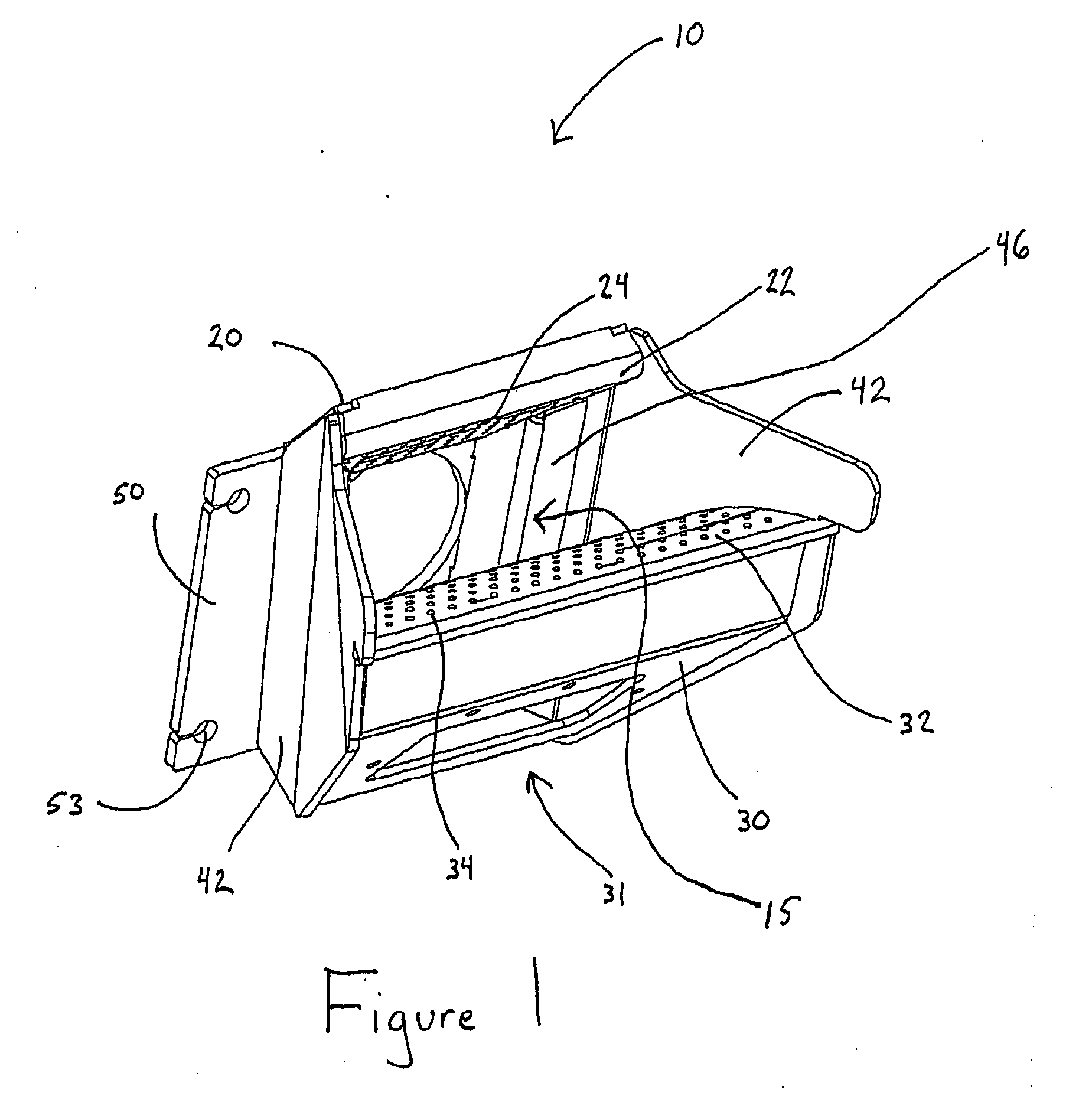

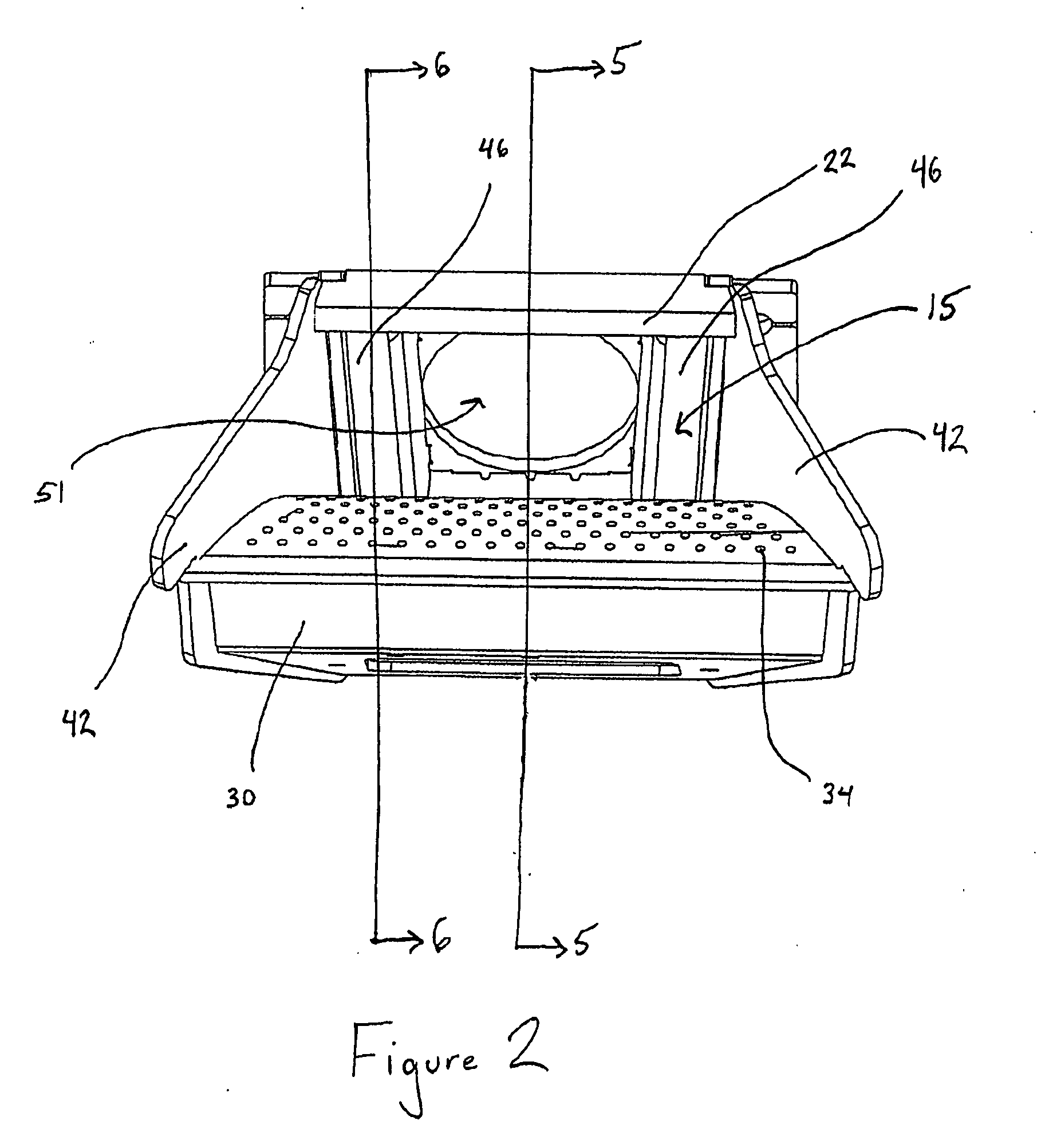

[0025]FIG. 7 illustrates a generalized sectional view of a solid particulate stove 100 in accordance with an exemplary embodiment of the invention. The stove 100 includes a hopper 6 in which fuel (not shown), such as wood pellets, wood chips, grains (e.g., shelled corn, barley, wheat, etc.), pelletized biofuels, anthracite coal, walnut shells, peach pits and the like, by way of example, or any other suitable particulate fuel or fuel mixture is stored prior to burning. The stove 100 also includes a feed system 2 that includes an auger 4 to feed fuel from the hopper 6 to a burnpot 10 positioned in a heavily insulated firebox 8. There, the fuel is mixed with oxygen and burned. One or more heat exchangers 5, typically with at least one surface positioned in the firebox 8, are provided to transfer heat from the firebox 8 to air flowing over an opposite surface of the heat exchangers 5 via a fan 7, following which the heated air is ejected into the environment to heat the surrounding spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com