Composite footwear upper and manufacturing method thereof

A technology for shoe uppers and composite sheets, which is applied to shoe uppers, footwear, footwear, etc., can solve the problems of difficult processing, large shoes, uncomfortable wearing, etc., and achieves the effect of simplifying the processing process and reducing the processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

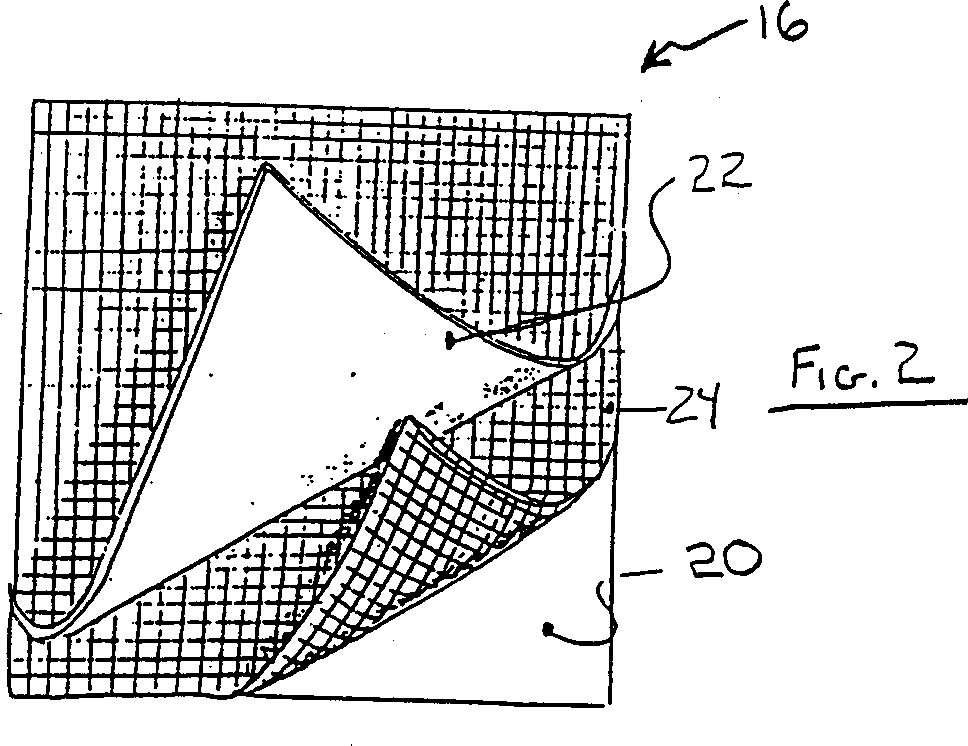

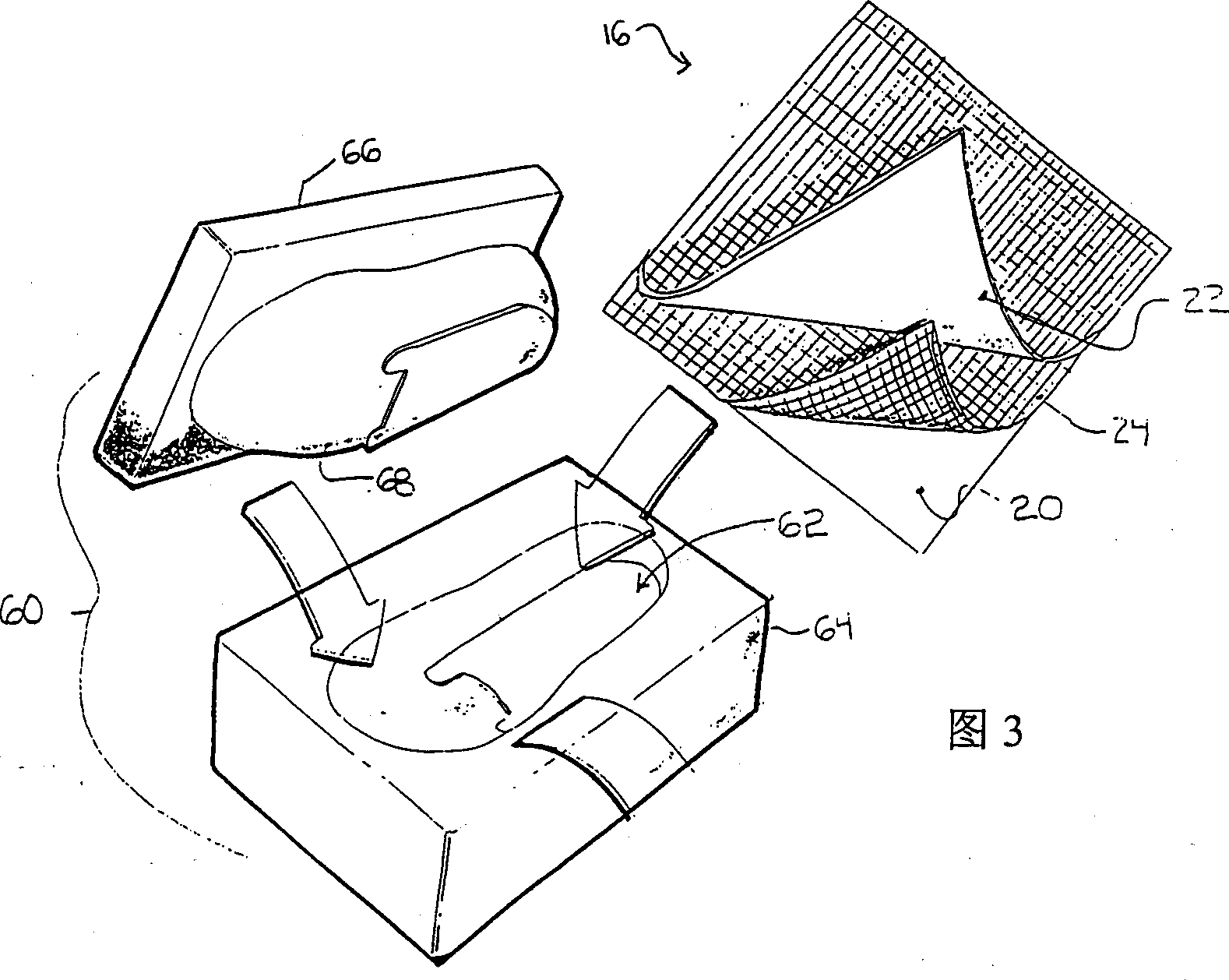

[0026] The invention provides a method for processing shoe uppers and general shoes, in which the multi-layered composite sheets are heated and activated to be stretchable and then put into a mold. The mold is used to press the composite sheet into the desired three-dimensional shape to form the composite upper. The formed upper can be attached to the sole together with other components to produce a shoe. The processing method of the invention simplifies the structure of the shoe, reduces the processing cost, and makes the processing of the shoe upper more flexible, so that the shoe has various characteristics.

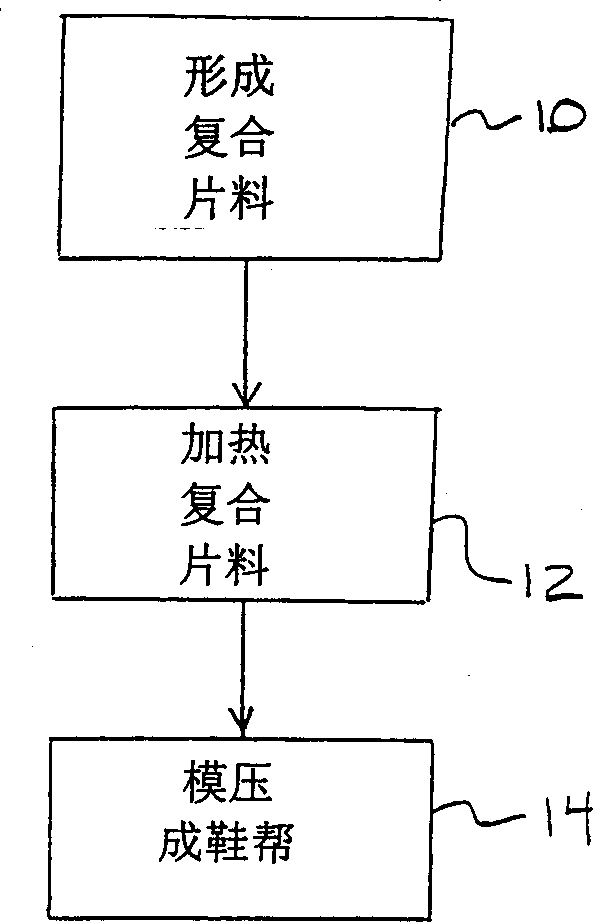

[0027] figure 1 The flowchart of shows generally a kind of method of processing shoe upper of the present invention. Wherein in step 10, two or more layers of materials are used to form a substantially planar composite sheet; in step 12, the substantially planar sheet is heated and activated to be extensible; in step 14, once the planar composite sheet is substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com