Novel building decorative plate material cutting forming machining method

A technology for architectural decoration and forming processing, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problem of reducing the bending efficiency of aluminum-plastic panels, the cumbersome cutting process of V-shaped grooves, and the unsightly bending of aluminum-plastic panels and other problems to achieve the effect of improving bending efficiency, avoiding offset, and avoiding secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

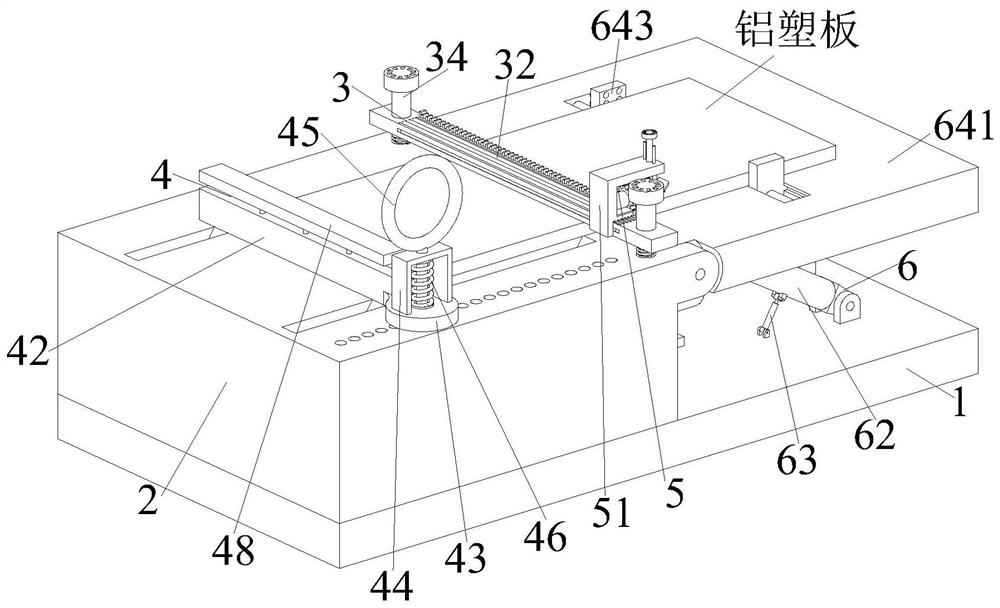

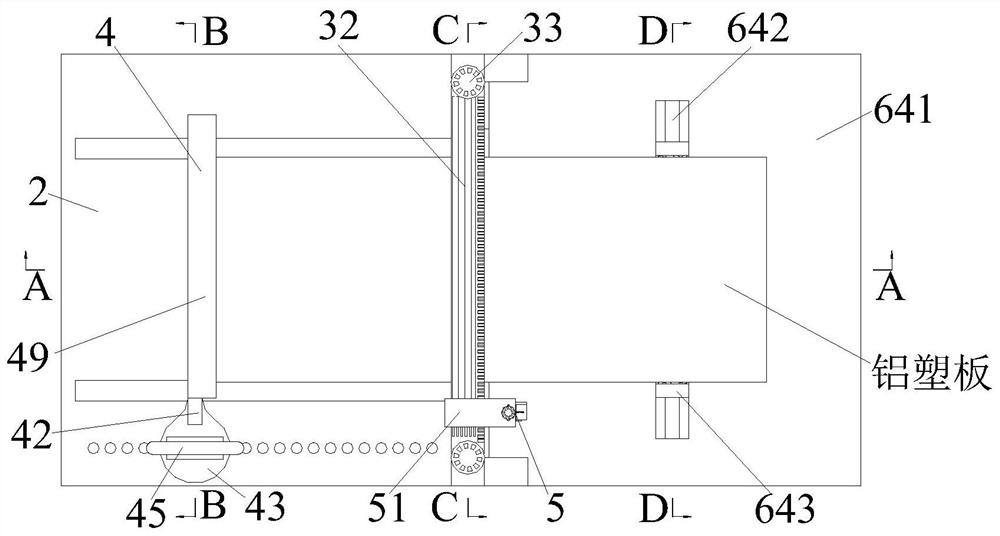

[0046] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 12 , to further elaborate the present invention.

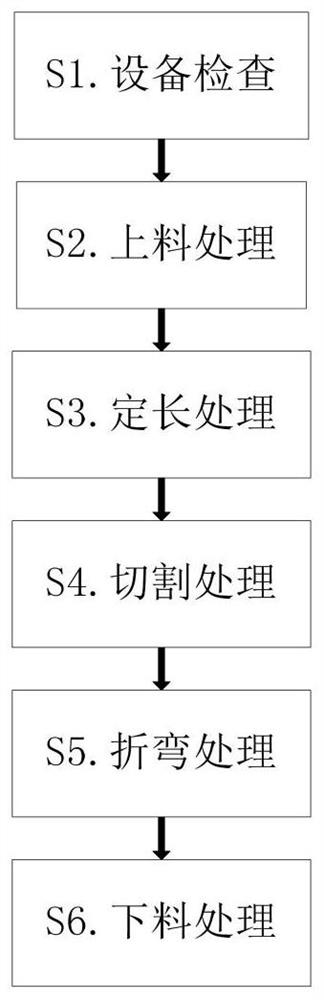

[0047] A new type of cutting and forming processing method for building decorative board materials, the specific forming processing method is as follows:

[0048] S1. Equipment inspection: before using the cutting and forming equipment for building decorative board materials to process building decorative boards, check them;

[0049] S2. Material loading process: After the equipment inspection is completed, manually place the aluminum-plastic plate to be bent on the workbench 2, so that the fixing device 3 locks and fixes it;

[0050] S3. Length-fixing treatment: After the aluminum-plastic panel is locked and fixed, the bending position is determined by the length-fixing device 4, so that the length-fixing device 4 performs length-fixing treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com