Coating method of imitation brick veneer

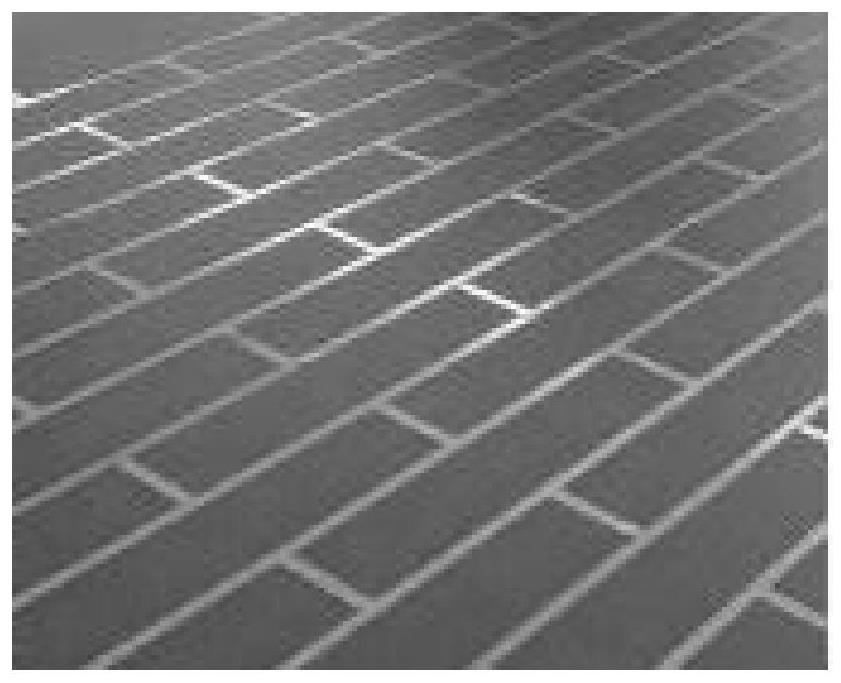

A coating method and imitation brick technology, which is applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve the problems that imitation brick finishes cannot be produced in batches, and achieve rich types of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

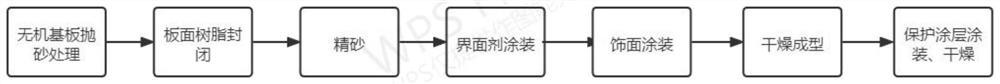

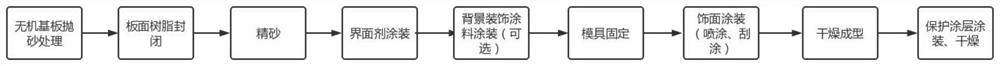

[0041] The following is attached with the manual Figure 2-7 The technical solution of the present invention is described in detail.

[0042] Such as Figure 2-7 As shown, the coating method of a kind of imitation brick veneer of the present invention mainly comprises the following steps carried out in order: (1) adopt 140-160 mesh sandpaper to carry out sandblasting treatment on the surface of the thermal insulation decorative panel veneer substrate , so that the surface flatness is less than or equal to 1mm; (2) Apply resin to the surface of the decorative substrate of the thermal insulation decorative board after the sandblasting treatment in step (1) and seal it until it is dry; after the sealing is completed, use 160-200 mesh sandpaper for fine sand treatment;

[0043] (3) Brush a layer of interface agent on the surface of the thermal insulation decorative board veneer substrate after the treatment in step (2), and the coating amount is 18-22g / m 2 , to dry;

[0044] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com