Production method of semi-conductive buffer water-blocking band

A production method and technology of water blocking tape, applied in the direction of insulation of conductors/cables, conductors, circuits, etc., can solve the problems of unsatisfactory electrical conductivity, unadvanced manufacturing process, affecting electrical conductivity, etc., and meet the normal working temperature. , Good water blocking effect and low volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

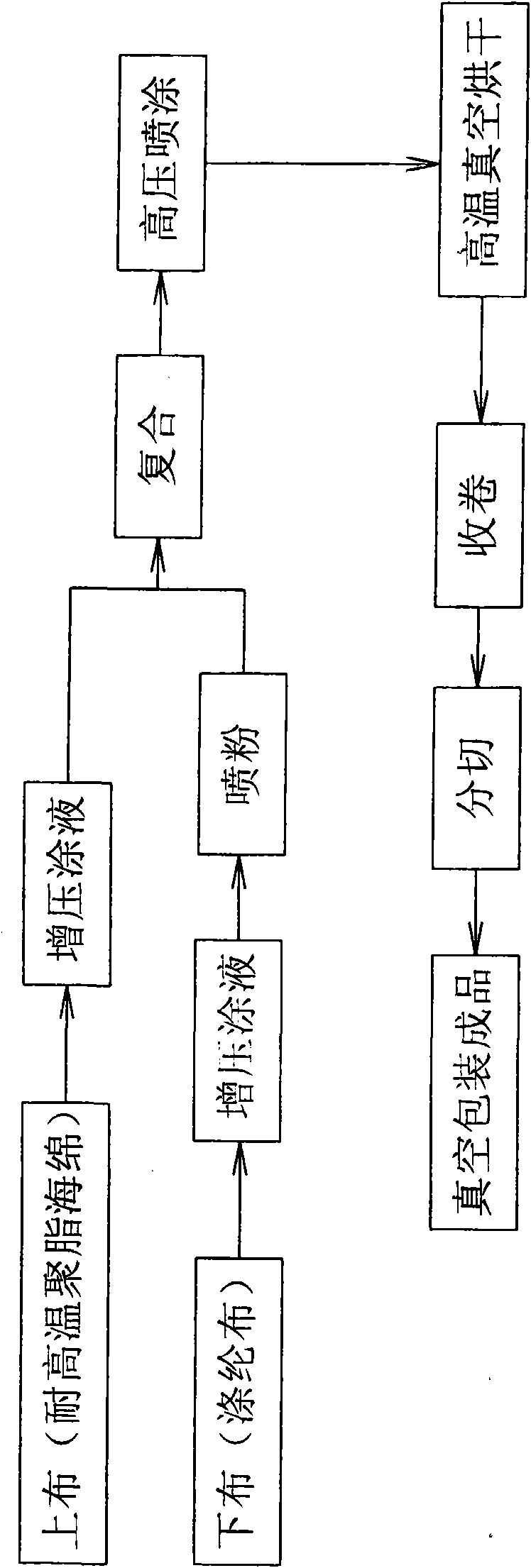

[0021] The present invention produces by following process route:

[0022] (1) with conductive liquid: the mass percent of each component in the conductive liquid is: the content of carbon is at 20%, acrylic acid is at 12%, mediocre is at 3%, dispersant is at 1.5%, and the rest is water. After the two components are mixed evenly, they are placed in a mixer and stirred at a stirring speed of 1200 rpm.

[0023] (2) Pressurized coating solution: impregnate the polyester cloth with conductive liquid in the pressurized rubber tank, and at the same time, the pressure in the pressurized rubber tank is greater than 4 times the atmospheric pressure, so that the conductive liquid is impregnated into the polyester cloth, and the polyester cloth is pressurized The running speed in the glue tank is 10-15 m / min.

[0024] (3) Dust spraying: Let the impregnated polyester cloth be evenly sprayed with a certain amount of super absorbent resin on its surface, and the powder spraying amount shou...

Embodiment 2

[0030] The present invention produces by following process route:

[0031] (1) with conductive liquid: the mass percent of each component in the conductive liquid is: the content of carbon is 30%, acrylic acid is at 10%, flat and good is at 2%, dispersant is at 1%, and the rest is water. After the components are mixed evenly, they are placed in a mixer and stirred at a stirring speed of 1000 rpm.

[0032] (2) Pressurized coating solution: impregnate the polyester cloth with conductive liquid in the pressurized rubber tank, and at the same time, the pressure in the pressurized rubber tank is greater than 4 times the atmospheric pressure, so that the conductive liquid is impregnated into the polyester cloth, and the polyester cloth is pressurized The running speed in the glue tank is 10-15 m / min.

[0033] (3) Dust spraying: Let the impregnated polyester cloth be evenly sprayed with a certain amount of super absorbent resin on its surface, and the powder spraying amount should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com