Method and device for detecting the degree of pollution in an operational converter

A pollution degree, converter technology, applied in output power conversion devices, emergency protection circuit devices that respond to undesired changes, and emergency protection devices that automatically disconnect, which can solve production interruptions, large follow-up costs, etc. problems, to achieve the effect of reducing cost and image loss, reducing the number of shutdowns, and improving the value of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

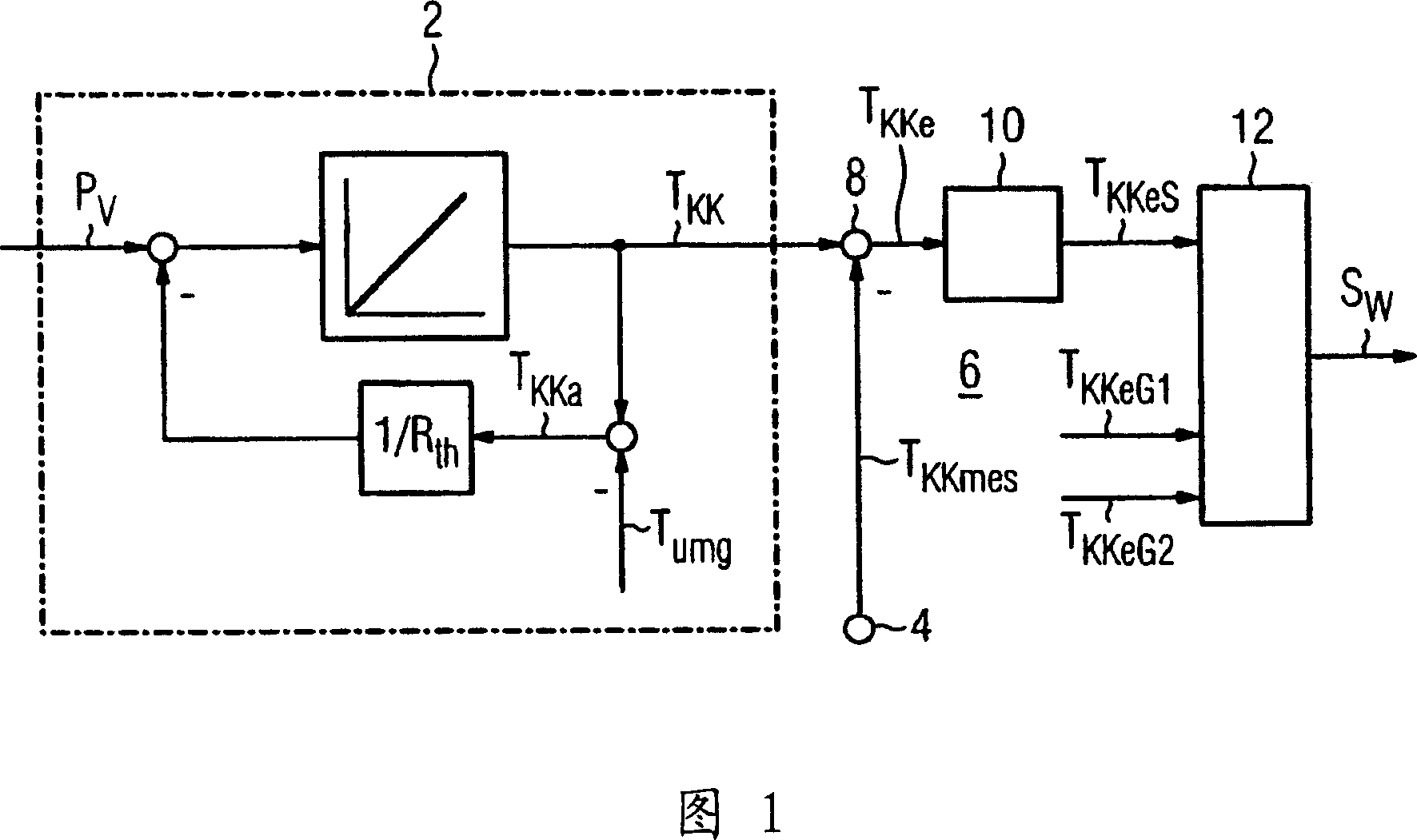

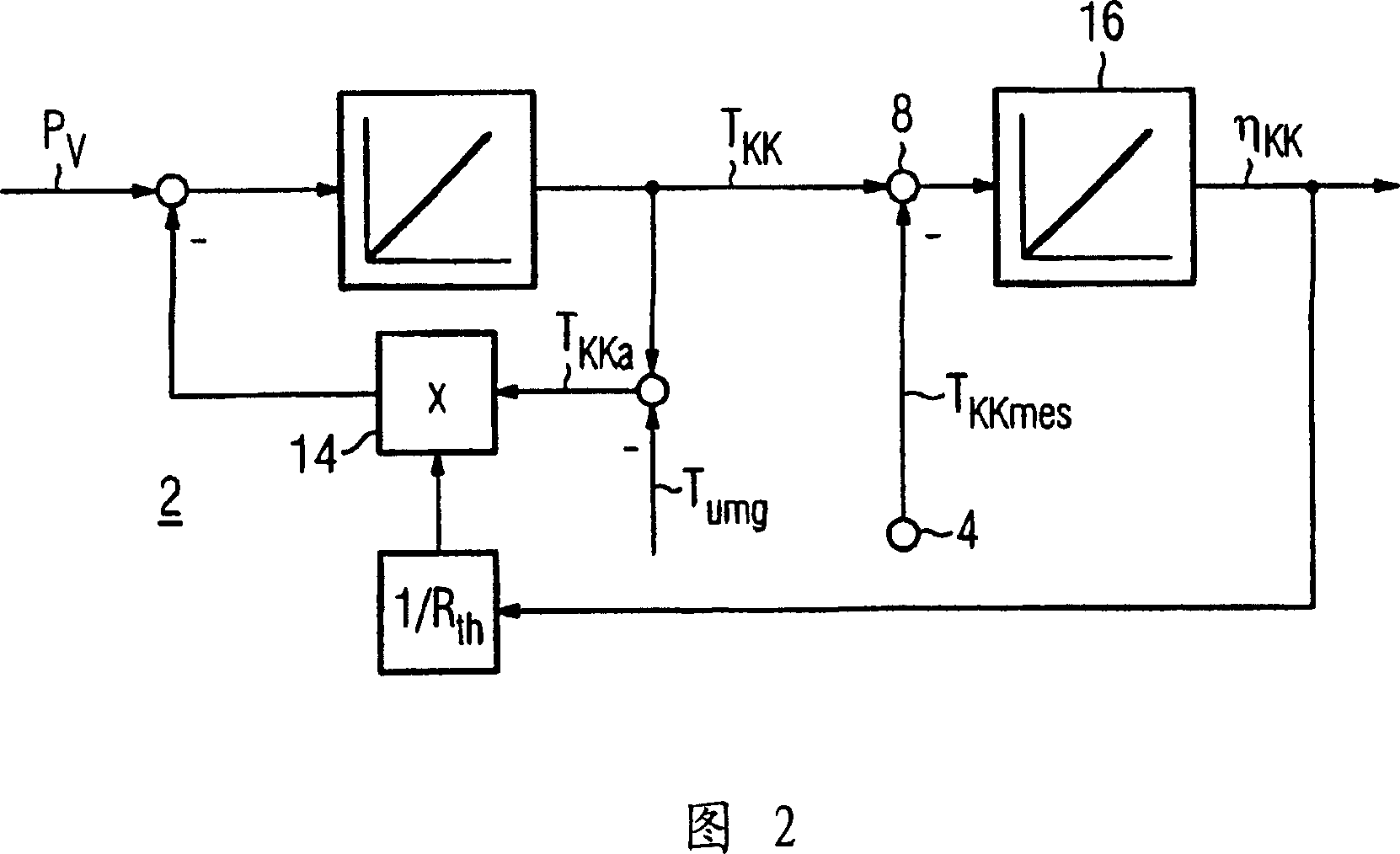

[0023] A preferred embodiment of the first device according to the invention is shown by way of example in FIG. 1 . The device has a temperature module 2 , a temperature sensor 4 and an evaluation circuit 6 . The temperature sensor 4 is placed on the part of the converter device whose temperature is to be measured. This component is the cooler of the converter device, which is in direct contact with the ambient air of the converter device. The temperature module 2 is a known temperature module for coolers. Use this temperature module according to the actual power loss P V and the actual cooling medium temperature T umg Determine the expected cooler temperature T KK . Here, the integral time constant corresponds to the thermal mass of the cooler, and the feedback coefficient corresponds to the cooler thermal resistance R th the reciprocal of . As in conventional thermal modules, to estimate the semiconductor barrier temperature, the power loss P is determined from the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com