Metallising using thin seed layer deposited using plasma-assisted process

A plasma and metallization technology, applied in the field of metallized plastic mesh and metallized plastic foil, can solve the problems of self-healing effect and disadvantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

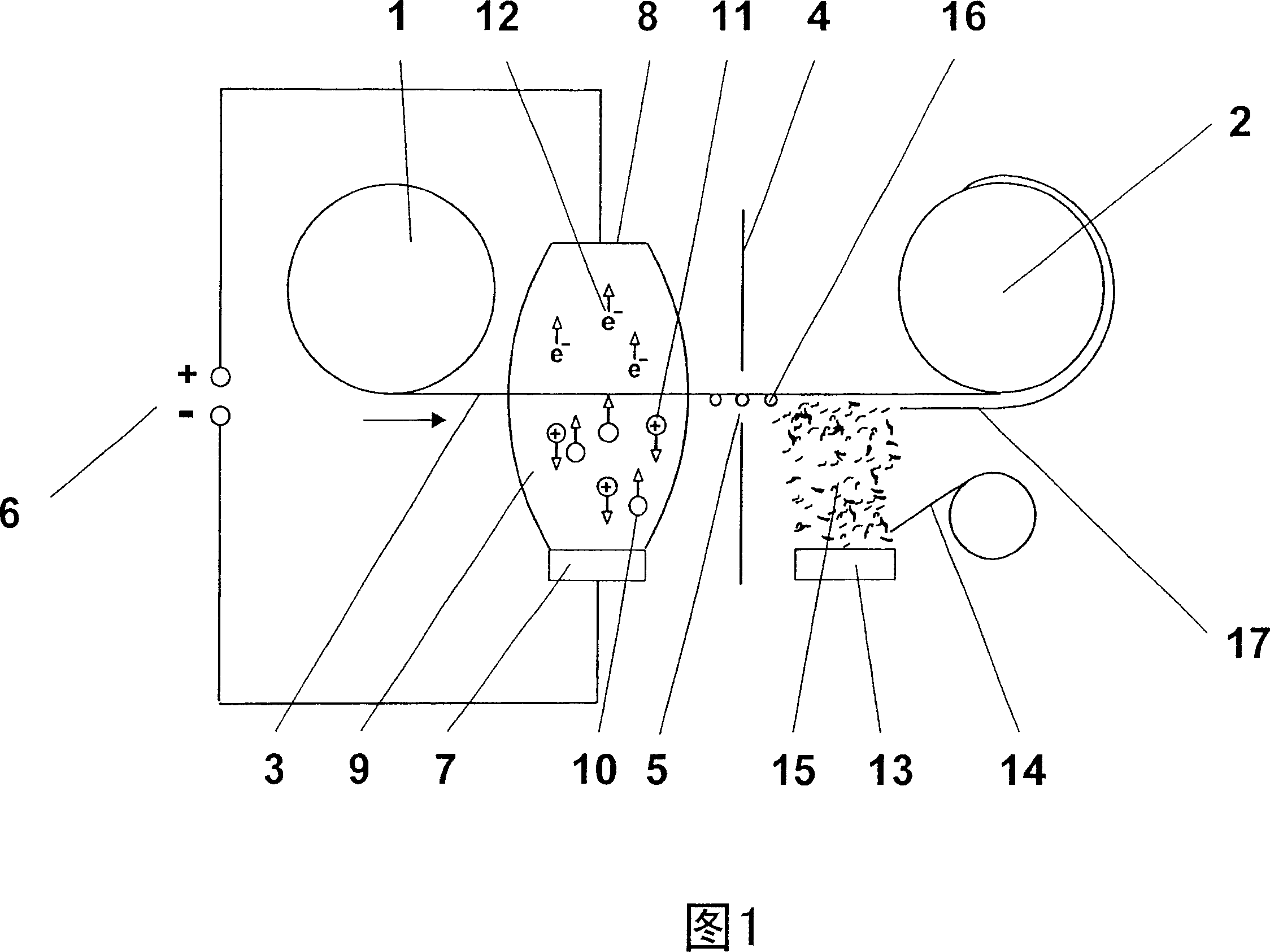

[0028] FIG. 1 represents a purely schematic illustration, in which only arranged components have been chosen to emphasize the basic principle, but these arranged components can deviate significantly under practical conditions.

[0029] The deposition machine has two rolls 1 and 2 . The plastic material (on which the deposition takes place) is set as foil 3 and this plastic foil is released from the first roll 1 according to the arrows shown next to roll 1 and moves towards roll 2, in roll 2 , the foil 3 is rolled up again accordingly.

[0030] Between the two rollers 1 and 2, two deposition or treatment stations are provided, which are preferably separated from each other by a chamber wall 4 in which an upper groove 5 or door assembly is provided, the foil The net 3 can be passed through the slot or door assembly described above.

[0031] The first deposition or processing station has a cathode 7 , an anode 8 and a DC power source or voltage source 6 , the negative terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com