High-strength conveying belt

A conveyor belt, high-strength technology, applied in the field of conveyor belts, can solve the problems of short service life, damage and fracture of conveyor belts, and achieve the effect of good weather resistance and strong tensile performance

Inactive Publication Date: 2016-06-01

戴小军

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The existing gravel conveyor belt is the most common conveyor belt. It is generally made of a simple layer of rubber material. The better quality generally uses nylon cloth in the rubber material. However, due to the long-term The friction and vibration of the existing sand and gravel conveyor belts have a short service life and are often damaged and broken

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

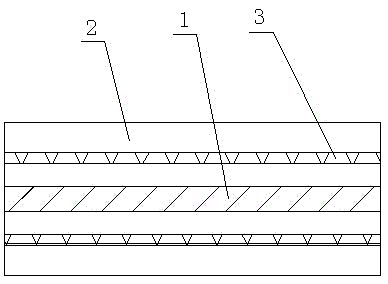

[0015] exist figure 1 Among them, the skeleton layer of the high-strength conveyor belt is nylon cloth 1, and the covering rubber layer 2 composed of thermoplastic elastomer material is on both sides of the nylon cloth 1, and a layer of stainless steel wire is arranged in the covering rubber layer 2 on both sides of the nylon cloth 1 net3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a high-strength conveying belt. A frame layer of the high-strength conveying belt is made of nylon cloth. Covering rubber layers composed of thermoplastic elastomer materials are arranged on the two sides of the nylon cloth. The covering rubber layers on the two sides of the nylon cloth are each internally provided with a layer of stainless steel mesh. The surface of the high-strength conveying belt is good in compression resistance, abrasion resistance and weather resistance, the tensile property in the length direction of the conveying belt is good, and the high-strength conveying belt is especially suitable for conveying gravels.

Description

technical field [0001] The invention relates to a conveyor belt, in particular to a conveyor belt for transporting sand and gravel. Background technique [0002] Conveyor belts are widely used in agriculture, industrial and mining enterprises, and transportation to transport various solid block and powder materials or finished items. The conveyor belt can be transported continuously, efficiently, and at a large inclination angle. The belt is easy to use, easy to maintain, low in freight, can shorten the transportation distance, reduce the project cost, and save manpower and material resources. [0003] Conveyor belt, also called conveyor belt, is a composite product of rubber, fiber and metal, or a composite product of plastic and fabric, which is used to carry and transport materials in a belt conveyor. The belt conveyor is continuous, high-efficiency, and transported at a large inclination angle. It is safe to operate, easy to use, easy to maintain, and low in freight. It...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65G15/34

Inventor 戴小军

Owner 戴小军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com