High-temperature lead-free halogen-free solder paste and preparation method thereof

A lead-free halogen-free solder paste, high temperature technology, applied in the field of high-temperature lead-free halogen-free solder paste and its preparation, achieves the effects of strong oxidation resistance, meeting environmental protection requirements and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

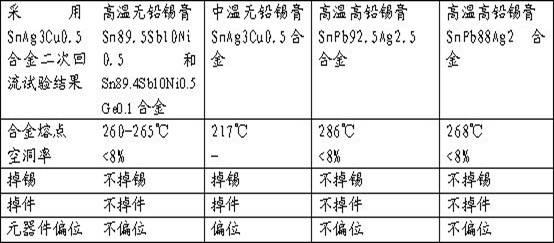

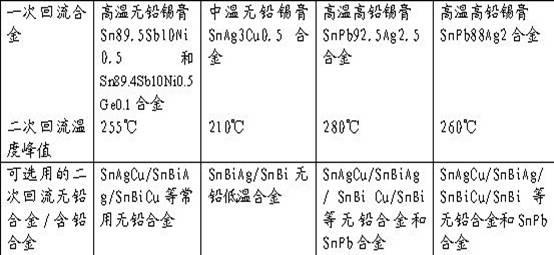

Method used

Image

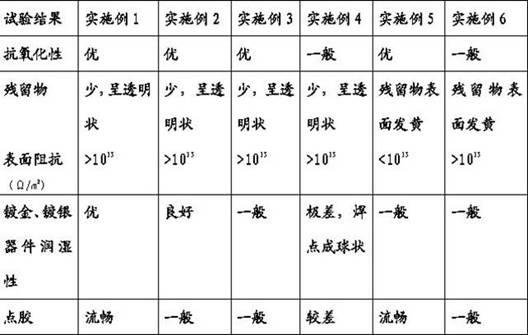

Examples

Embodiment 1

[0045] In the reactor, add 25 grams of high softening point rosin resin, 24 grams of polymerized rosin, 19 grams of diethylene glycol monocapryl ether, 15 grams of triethyl carbitol ether, 3 grams of succinic acid, 2.5 grams of dipropionic acid, 1 gram of triethanolamine, 4 grams of ethylimidazole were mixed and stirred evenly, heated until completely dissolved to prepare a mixed solution, and when the mixed solution was cooled to 80°C, 1.5 grams of polyethylene glycol type nonionic surfactant and 5 grams of stearin were added Acid amide, then fully stir evenly, and then continue to cool to room temperature to become a paste. After standing for 12 hours or refrigerated for 12 hours, the paste completely recovers thixotropy to prepare solder paste. Take 20 grams of solder paste and 80 grams of Sn89.5Sb10Ni0.5 in a mixing barrel and stir evenly to obtain high-temperature lead-free Halogen-free solder paste. Then pack it into cans or syringes according to the requirements of the...

Embodiment 2

[0047] In the reactor, add 28 grams of high softening point rosin resin, 24 grams of polymerized rosin, 19 grams of diethylene glycol monocaprylyl ether, 15 grams of triethyl carbitol ether, 3 grams of succinic acid, 2 grams of dipropionic acid, 1 gram of triethanolamine, 4 grams of phenylacryltriazole were mixed and stirred evenly, and heated until completely dissolved to prepare a mixed solution. When the mixed solution was cooled to 80° C., 1 gram of polyethylene glycol type nonionic surfactant, 2 grams of Stearic acid amide and 3 grams of modified hydrogenated castor oil are fully stirred evenly again, then continue to cool to room temperature and become paste. After standing for 12 hours or refrigerated for 12 hours, the paste completely recovers thixotropy to prepare solder paste. Take 15 grams of solder paste and 85 grams of Sn89.5Sb10Ni0.5 in a mixing barrel and stir evenly to obtain high-temperature lead-free Halogen-free solder paste. Then pack it into cans or syrin...

Embodiment 3

[0049]In the reaction kettle, add 20 grams of high softening point rosin resin, 10 grams of polymerized rosin, 19 grams of hydrogenated abietyl alcohol, 19 grams of diethylene glycol monooctyl ether, 15 grams of hexanediol, 3 grams of succinic acid, and 2.5 grams of dipropionic acid , 2.5 grams of itaconic acid, 1 gram of triethanolamine, and 5 grams of ethyl imidazole were mixed and stirred evenly, and heated until completely dissolved to prepare a mixed solution. When the mixed solution was cooled to 80 ° C, 0.5 gram of polyethylene glycol-type non-ionic surface was added Active agent and 5 grams of stearic acid amide are fully stirred again, then continue to cool to room temperature and become paste. After standing for 12 hours or refrigerated for 12 hours, the paste will completely recover the thixotropy to prepare soldering paste. Take 9 grams of soldering paste and 91 grams of Sn89.4Sb10Ni0.5Ge0.1 in the mixing barrel and stir evenly to obtain high temperature Lead-free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com