High-nickel cathode material rich in rock salt phase on the surface, and a preparation method and application thereof

A positive electrode material, high-nickel technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of comprehensive performance of ternary materials, unstable surface chemical properties of materials, poor effect of ternary materials, etc. , to achieve significant cycle performance, great theoretical and practical significance, and broad prospects for commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

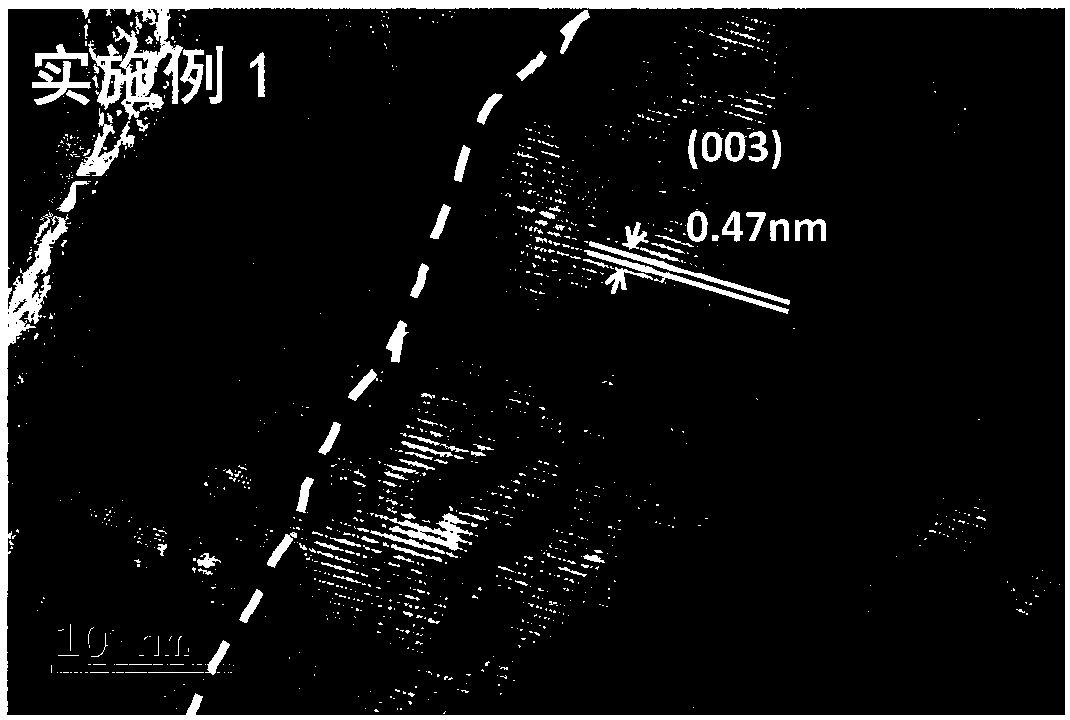

Embodiment 1

[0044] Embodiment 1 of the present invention provides a method for preparing a high-nickel ternary positive electrode material for a lithium-ion battery doped with transition metal ions in a high-valence state and whose surface is rich in rock-salt phase. The specific steps are as follows:

[0045] (1) Take 300g Ni 0.88 co 0.09 Al 0.03 (OH) 2 precursor with 3.16g MnO 2 The particles are mixed evenly (weighed according to 1% coating amount), and then mixed at a high speed in a mechanical fusion machine with a line speed of 13m / s and a mixing time of 5min to obtain a uniform surface coating of MnO 2 Ni 0.88 co 0.09 Al 0.03 (OH) 2 Precursor, evenly coated with MnO 2 Ni 0.88 co 0.09 Al 0.03 (OH) 2 The scanning electron microscope pictures of the precursors are shown in figure 1 ;

[0046] (2) Molar ratio Li: (Ni+Co+Al)=1.03:1 ratio lithium hydroxide and step (1) are coated with MnO 2 Ni 0.88 co 0.09 Al 0.03 (OH) 2 Precursors are mixed and calcined in an oxygen a...

Embodiment 2

[0052] Embodiment 2 of the present invention provides a method for preparing a high-nickel ternary positive electrode material for a lithium-ion battery doped with transition metal ions in a high-valence state and whose surface is rich in rock-salt phase. The specific steps are as follows:

[0053] (1) Take 300g Ni 0.88 co 0.09 Al 0.03 (OH) 2 precursor with 6.32g MnO 2 The particles are mixed evenly (weighed according to the coating amount of 2%), and then mixed at a high speed in a mechanical fusion machine with a line speed of 13m / s and a mixing time of 5min to obtain a uniform surface coating of MnO 2 Ni 0.88 co 0.09 Al 0.03 (OH) 2 Precursor, evenly coated with MnO 2 Ni 0.88 co 0.09 Al 0.03 (OH) 2 The scanning electron microscope pictures of the precursors are shown in Figure 4 ;

[0054] (2) By molar ratio Li: (Ni+Co+Al)=1.03:1 lithium hydroxide and step (1) are coated with MnO 2 Ni 0.88 co 0.09 Al 0.03 (OH) 2 Precursors are mixed and calcined in an oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com