Modified polyphenylene oxide resin composition comprising carbon nano tube

A technology of polyphenylene ether resin and resin composition, used in rigid containers, containers, packaging, etc., can solve the problems of non-resistance supply at the injection gate part, pollution of the packaging part, poor surface resistance of semiconductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

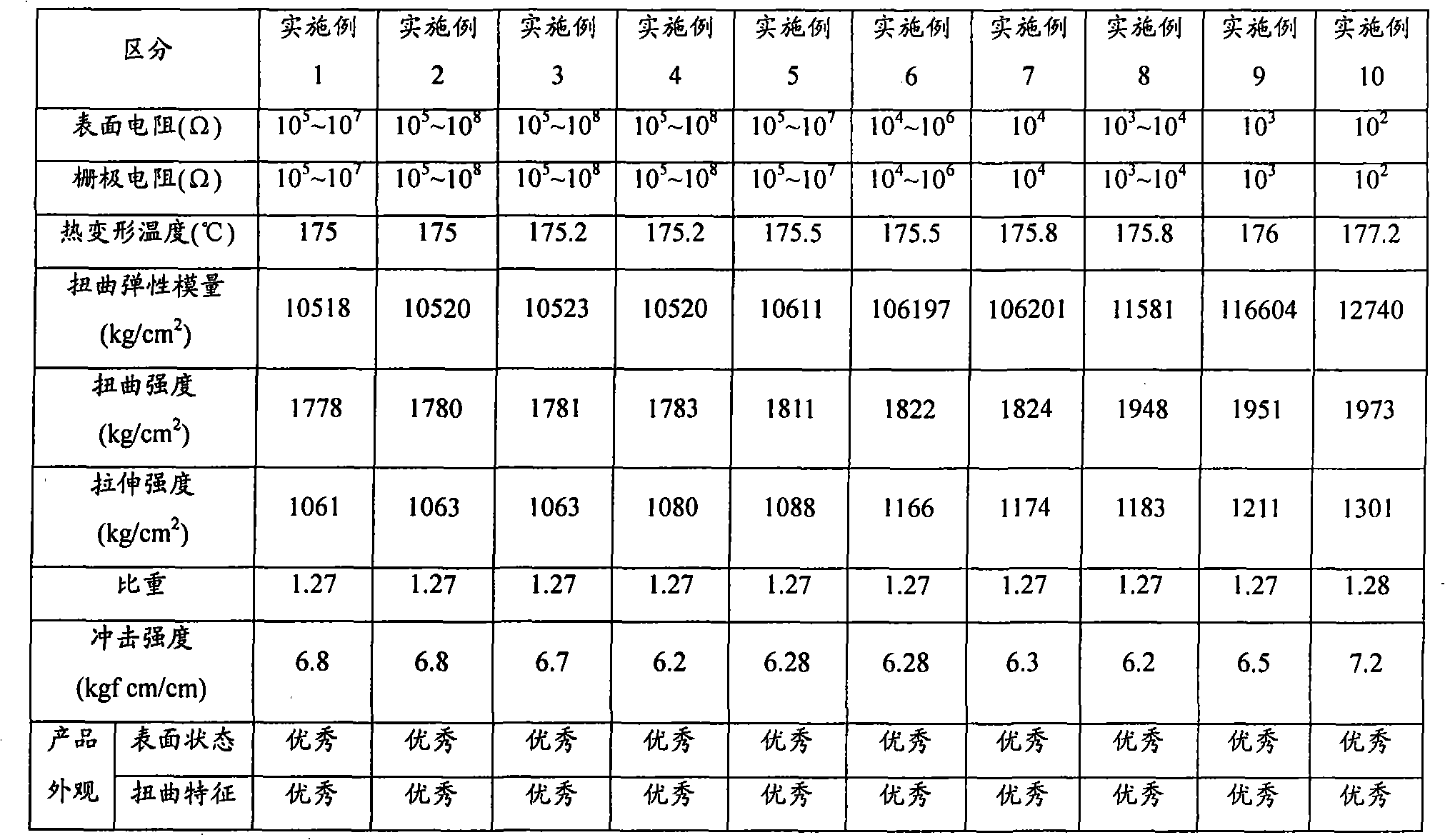

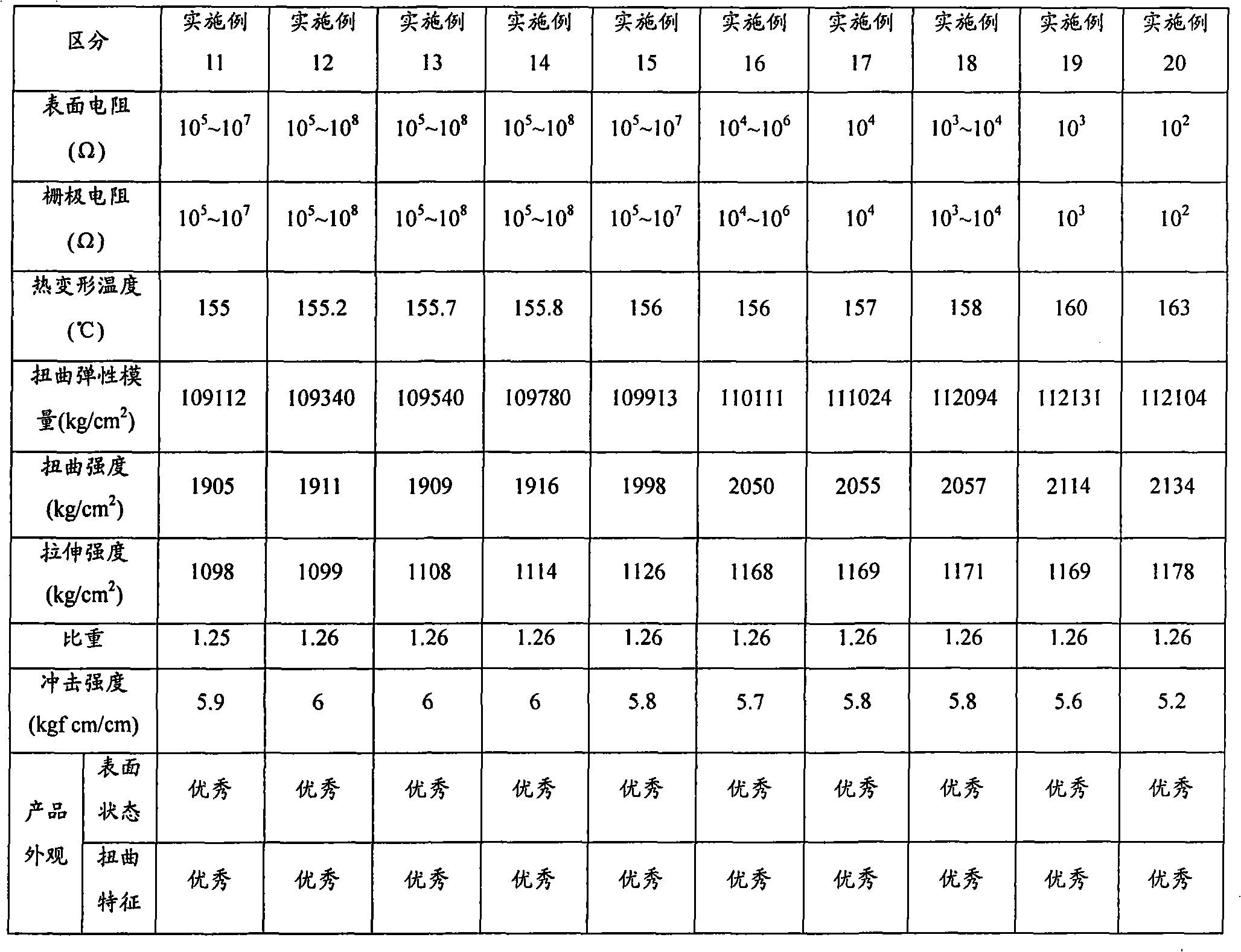

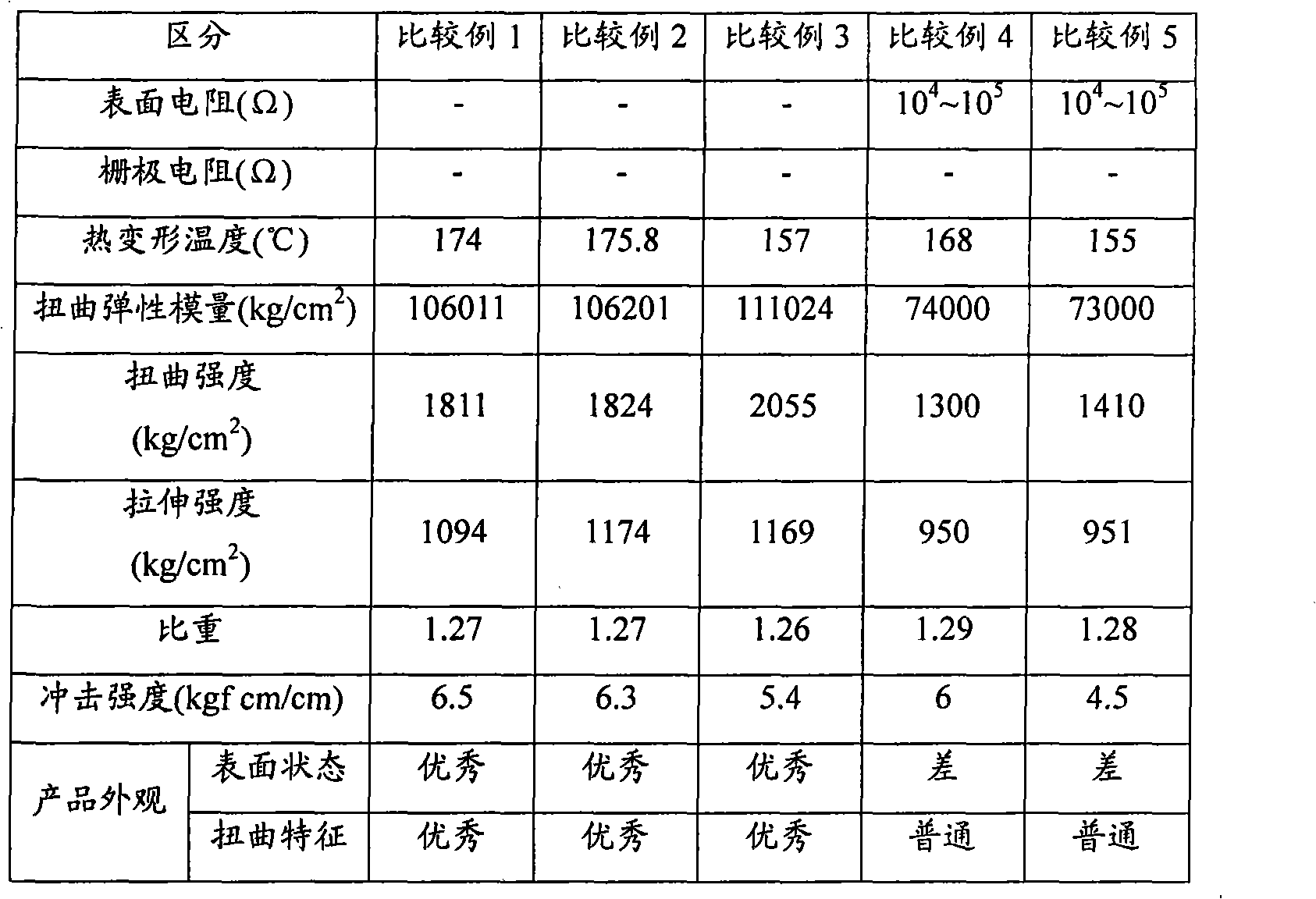

[0055] Examples 1-20: Manufacture of modified polyphenylene ether (MPPO) resin composition

[0056] The carbon nanotube-containing MPPO resin composition of the present invention was produced with the compositions and contents shown in Tables 1 and 2 below.

[0057] The composition of Table 1 is a composition used for a semiconductor tray whose baking temperature of a semiconductor is 150 degreeC, and the composition of Table 2 is a composition used for a semiconductor tray whose baking temperature of a semiconductor is 130 degreeC.

[0058] In the composition, the viscosity of the PPO resin used is 0.4dl / g product (manufactured by Asahi), and the carbon nanotube uses the product (average diameter 20nm, average length 10 μm, Purity above 90UT%, aspect ratio (ASPECT RATIO) above 500).

[0059] The glass fiber uses CS03-165A manufactured by Korea's Austin (オエンスココニン) company, and the mineral filler uses a mixture of 60 to 75% by weight of silicon dioxide and 25 to 40% by weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com