Polyether polyamide resin composition

A technology of polyether polyamide and resin composition, which is applied in the field of polyether polyamide resin composition to achieve the effects of strong strength, high toughness and excellent tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0247] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to these. In addition, various measurements in this Example were performed by the following methods.

[0248] [Evaluation method]

[0249] The relative viscosity, number average molecular weight, glass transition temperature, crystallization temperature, melting point, moisture content, density, and phosphorus atomic concentration of the polyether polyamide resin (A1) or (A2) used in Examples and Comparative Examples, and the following The water content, phosphorus atomic concentration, Charpy impact strength, and tensile modulus of the polyether polyamide resin composition obtained in the method were measured as follows.

[0250] (1) relative viscosity (ηr)

[0251] Accurately weigh 0.2g of sample, and dissolve it in 20ml of 96% sulfuric acid with stirring at 20-30°C. After complete dissolution, quickly measure 5 ml of the solution into a Cannon-Finks type visc...

manufacture example 1

[0288] Put 1169.20 g of adipic acid, 10.47 g of sodium hypophosphite monohydrate, and 7.294 g of sodium acetate into a reaction container with a volume of about 50 L equipped with a stirrer, a nitrogen gas inlet, and a condensed water outlet, and fully replace the container with nitrogen. , and melted at 170° C. while supplying a small amount of nitrogen gas.

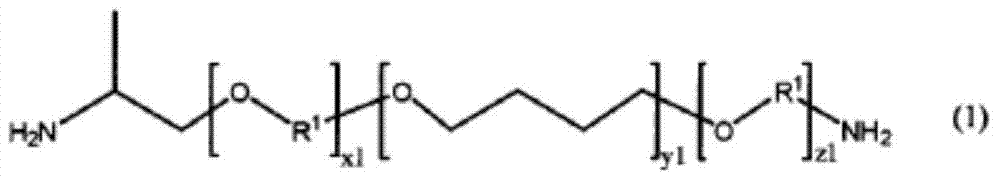

[0289] While slowly raising the temperature to 260° C., 1,3-bis(aminomethyl)benzene [m-xylylenediamine: m-xylylenediamine: MXDA] 1078.70 g and polyether diamine as the polyether diamine compound (a1-1) [U.S. HUNTSMAN Co., trade name: XTJ-542: Based on the catalog of U.S. HUNTSMAN Co., the following formula (1-1) It means that the approximate number of x1+z1 is 6.0, the approximate number of y1 is 9.0, and the number average molecular weight is 1000. ] 800.00 g of the mixed solution was polymerized for about 2 hours to obtain a polyether polyamide resin (A1).

[0290] Table 1 shows the results of the above evaluation m...

Embodiment 1-1

[0293] In the manner that the polyether polyamide resin (A1) obtained in the above-mentioned Production Example 1 reaches the composition shown in Table 1, weigh other components, blend the components except glass fibers with a drum, and extrude from a twin-screw After the base of the discharge machine ("TEM37BS" manufactured by Toshiba Machine Co., Ltd.) was charged and melted, the glass fiber was side-fed. The set temperature of the extruder was 280°C up to the side feeder and 260°C from the side feeder, and extruded and pelletized to produce polyether polyamide resin composition pellets .

[0294] The obtained pellets of the polyether polyamide resin composition were dried with dehumidified air at 80° C. (dew point −40° C.) for 8 hours.

[0295] Table 1 shows the results of the above evaluation method for this polyether polyamide resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com