Polyolefin composition comprising hollow glass microspheres

A technology of glass microspheres and compositions, which is applied in the field of polyolefin compositions, and can solve problems such as reducing strength and tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

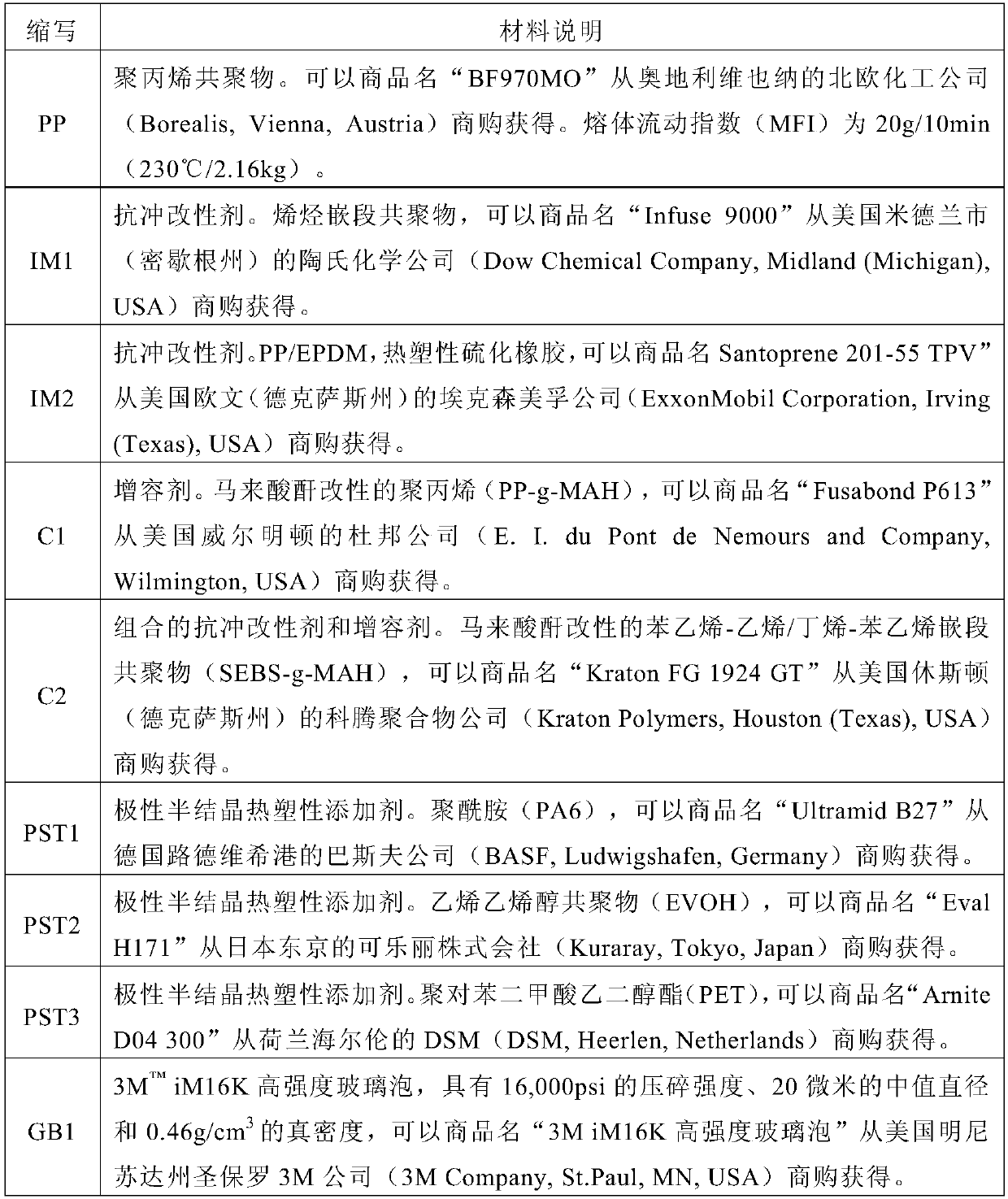

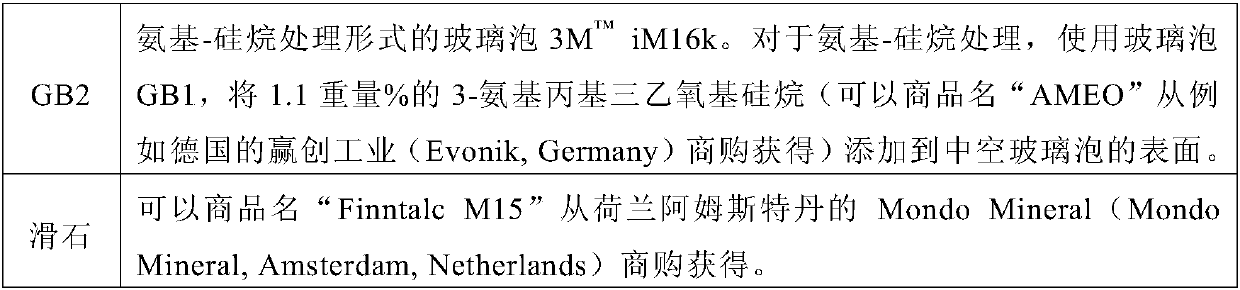

[0079] Material

[0080] Table 1: List of materials used in the examples

[0081]

[0082]

[0083] Silane Surface Treatment of Glass Bubbles

[0084] 1500 g of a 0.5% by weight aqueous solution of 3-aminopropyltriethoxysilane (commercially available under the trade designation "AMEO" from Evonik, Germany) was charged to a Ross mixer (available from Harbin, NY). Parker's Charles Ross & Son Company (Charles Ross & Son Company, Hauppauge, N.Y.)). Glass bubbles (available from 3M Company, St. Paul, MN, USA) under the trade designation "iM16k" were added slowly at a moderate mixing speed and a mixing time of 15 minutes. The glass bubbles were added in such a way that a coating quantity of 1.1% by weight was achieved. The resulting paste was poured into aluminum pans and dried overnight in a forced air oven at 80°C. The dried glass bubbles were screened through a 180 micron sieve to remove any lumps.

[0085] Compounding process

[0086] A masterbatch with 26% b...

Embodiment approach 1

[0116] Embodiment 1: A composition comprising at least one of an impact modifier or a compatibilizer, a polyolefin, hollow glass microspheres, and a polar semicrystalline thermoplastic additive.

Embodiment approach 2

[0117] Embodiment 2: The composition of Embodiment 1, wherein the hollow glass microspheres are present in a range of 0.2% to 49% by weight, based on the total weight of the composition, and the polar semicrystalline thermoplastic The additive is present in a range of 0.5% to 49.3% by weight, the impact modifier is present in a range of 0% to 49.3% by weight, and the compatibilizer is present in a range of 0% to 20% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com