Preparation method of polyimide/sisal cellulose micro-crystalline shape memory composite material

A technology of cellulose microcrystals and composite materials, which is applied in the field of preparation of polyimide/sisal cellulose microcrystal shape memory composite materials, can solve problems that have not been reported in the literature, achieve excellent tensile modulus, and be easy to use. Large-scale promotion and application, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

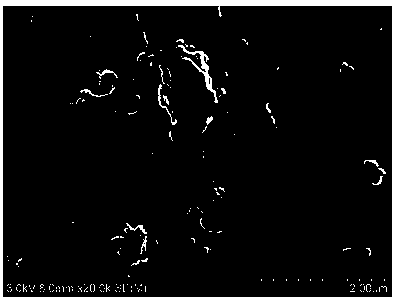

Image

Examples

Embodiment 1

[0016] (1) The sisal cellulose crystallites were dried in an oven at 100 °C for 3 h to obtain the dried sisal cellulose crystallites.

[0017] (2) Weigh 0.0025 mol of ODA, add it into a three-necked flask, add a clean small magnet, then inject 10 mL of NMP, turn on the magnetic stirrer, adjust the rotation speed to 300 rpm, then add 0.0025 mol of ODPA and the steps (1) For the dried sisal cellulose microcrystals, the whole process of adding raw materials and reagents was completed within 15 min, and then the reaction was stirred at 25 °C for 24 h under a nitrogen atmosphere to obtain a viscous sisal containing sisal The PAA solution of cellulose microcrystals; the consumption of the dried sisal cellulose microcrystals is 1% of the total mass of ODA and ODPA.

[0018] (3) ultrasonically dispersing the PAA solution containing sisal cellulose microcrystals prepared in step (2) for 30 min, and after the ultrasonic dispersion is completed, evenly smear the PAA solution containing s...

Embodiment 2

[0020] (1) The sisal cellulose crystallites were dried in an oven at 100 °C for 3 h to obtain the dried sisal cellulose crystallites.

[0021] (2) Weigh 0.0025 mol of ODA, add it into a three-necked flask, add a clean small magnet, then inject 10 mL of NMP, turn on the magnetic stirrer, adjust the rotation speed to 300 rpm, then add 0.0025 mol of ODPA and the steps (1) For the dried sisal cellulose microcrystals, the whole process of adding raw materials and reagents was completed within 15 min, and then the reaction was stirred at 25 °C for 24 h under a nitrogen atmosphere to obtain a viscous sisal containing sisal PAA solution of cellulose microcrystal; the consumption of the dried sisal cellulose microcrystal is 1.5% of the total mass of ODA and ODPA.

[0022] (3) ultrasonically dispersing the PAA solution containing sisal cellulose microcrystals prepared in step (2) for 30 min, and after the ultrasonic dispersion is completed, evenly smear the PAA solution containing sisal...

Embodiment 3

[0024] (1) The sisal cellulose crystallites were dried in an oven at 100 °C for 3 h to obtain the dried sisal cellulose crystallites.

[0025] (2) Weigh 0.0025 mol of ODA, add it into a three-necked flask, add a clean small magnet, then inject 10 mL of NMP, turn on the magnetic stirrer, adjust the rotation speed to 300 rpm, then add 0.0025 mol of ODPA and the steps (1) For the dried sisal cellulose microcrystals, the whole process of adding raw materials and reagents was completed within 15 min, and then the reaction was stirred at 25 °C for 24 h under a nitrogen atmosphere to obtain a viscous sisal containing sisal The PAA solution of cellulose microcrystals; the consumption of the dried sisal cellulose microcrystals is 2% of the total mass of ODA and ODPA.

[0026] (3) ultrasonically dispersing the PAA solution containing sisal cellulose microcrystals prepared in step (2) for 30 min, and after the ultrasonic dispersion is completed, evenly smear the PAA solution containing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com