Method and device for producing a fiber composite material

A technology of fiber composite materials and composite materials, which is applied in the field of composite material production and can solve problems such as unstable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

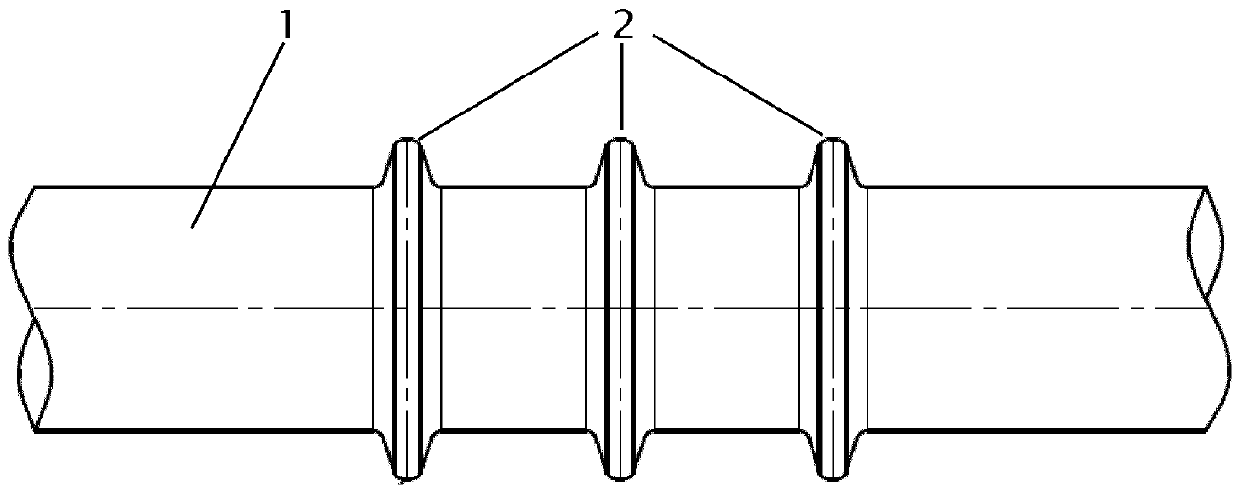

[0034] figure 1 The deflection rod 1 depicted in has three radially surrounding projections 2 which, in this case, are arranged in the region of the deflection rod above which the fiber bundle is guided.

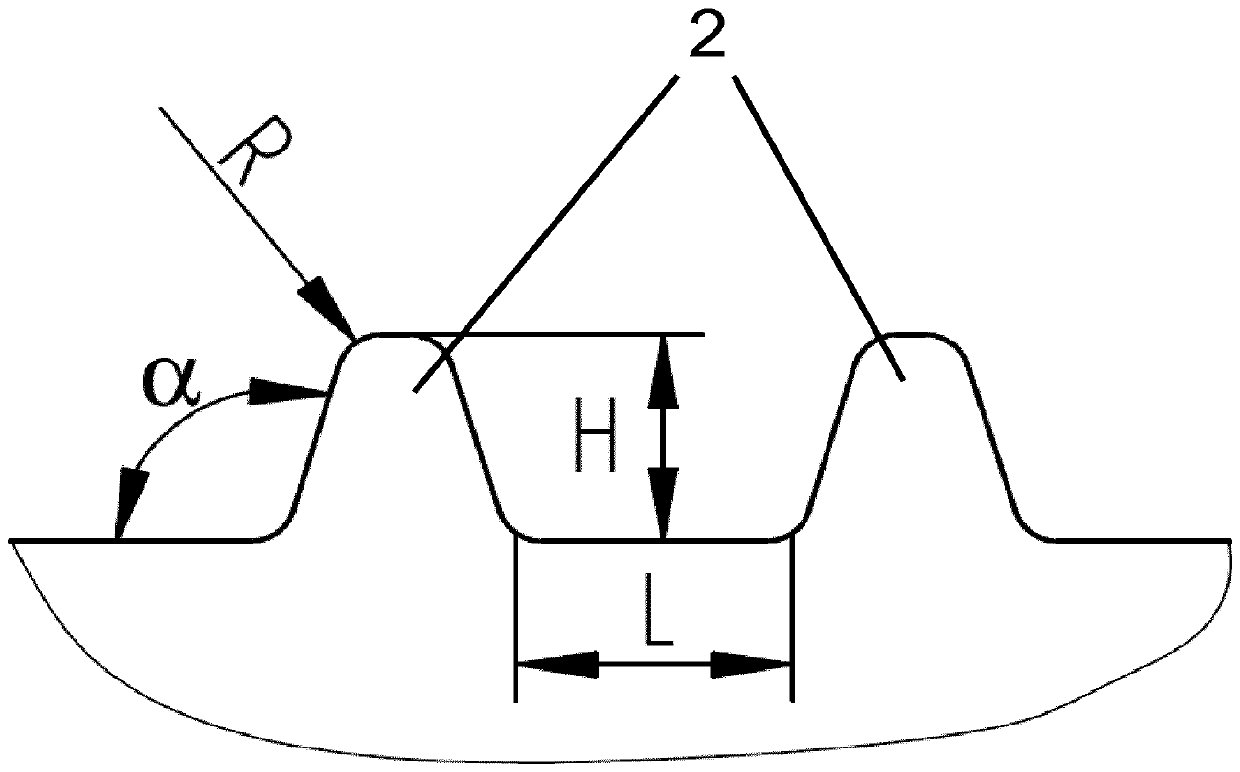

[0035] figure 2 More specifically two protrusions 2 are illustrated. The protrusion has a side angle α, a height H, and a radius R with a rounded tip. Located between the protrusions are straight sections of length L, which may be, for example, 0.5 to 6 times the width of the original roving. The side angle α is preferably 90.1° to 100°, especially preferably 90.3° to 95°, and particularly preferably 90.5° to 92°, while the height H is preferably 0.2 mm to 20 mm, especially preferably 0.5 mm to 10 mm, particularly preferably 1 mm to 6 mm, and very particularly preferably 2 mm to 4 mm. The radius R is preferably 0.1 mm to 10 mm, particularly preferably 0.1 mm to 5 mm, and particularly preferably 0.2 to 2 mm. The radius is based on rounding the tip.

[0036] A particula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com