Preparation device of ultra-high molecular weight polyethylene sheets and preparation method thereof

A technology of ultra-high molecular weight and preparation equipment, which is applied in the field of ultra-high molecular weight polyethylene sheet preparation equipment, can solve the problems of low degree of automation of the production line, limitation of thickness and sheet strength, complex production line structure, etc., and achieve thickness uniformity and Improved dimensional stability, high production efficiency, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

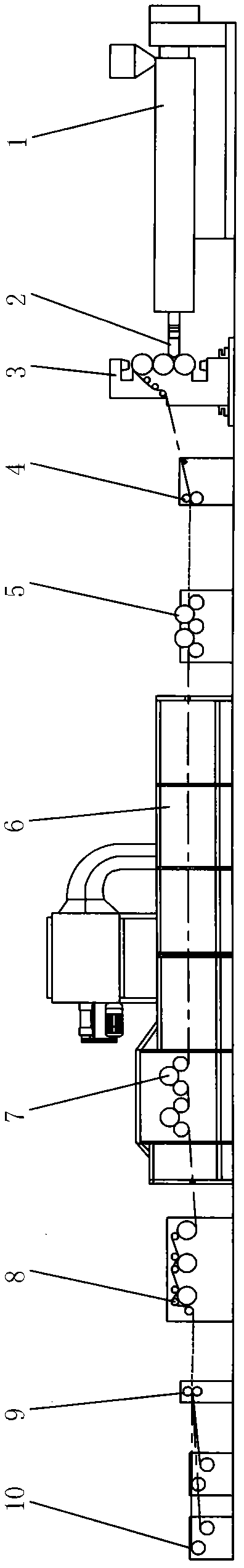

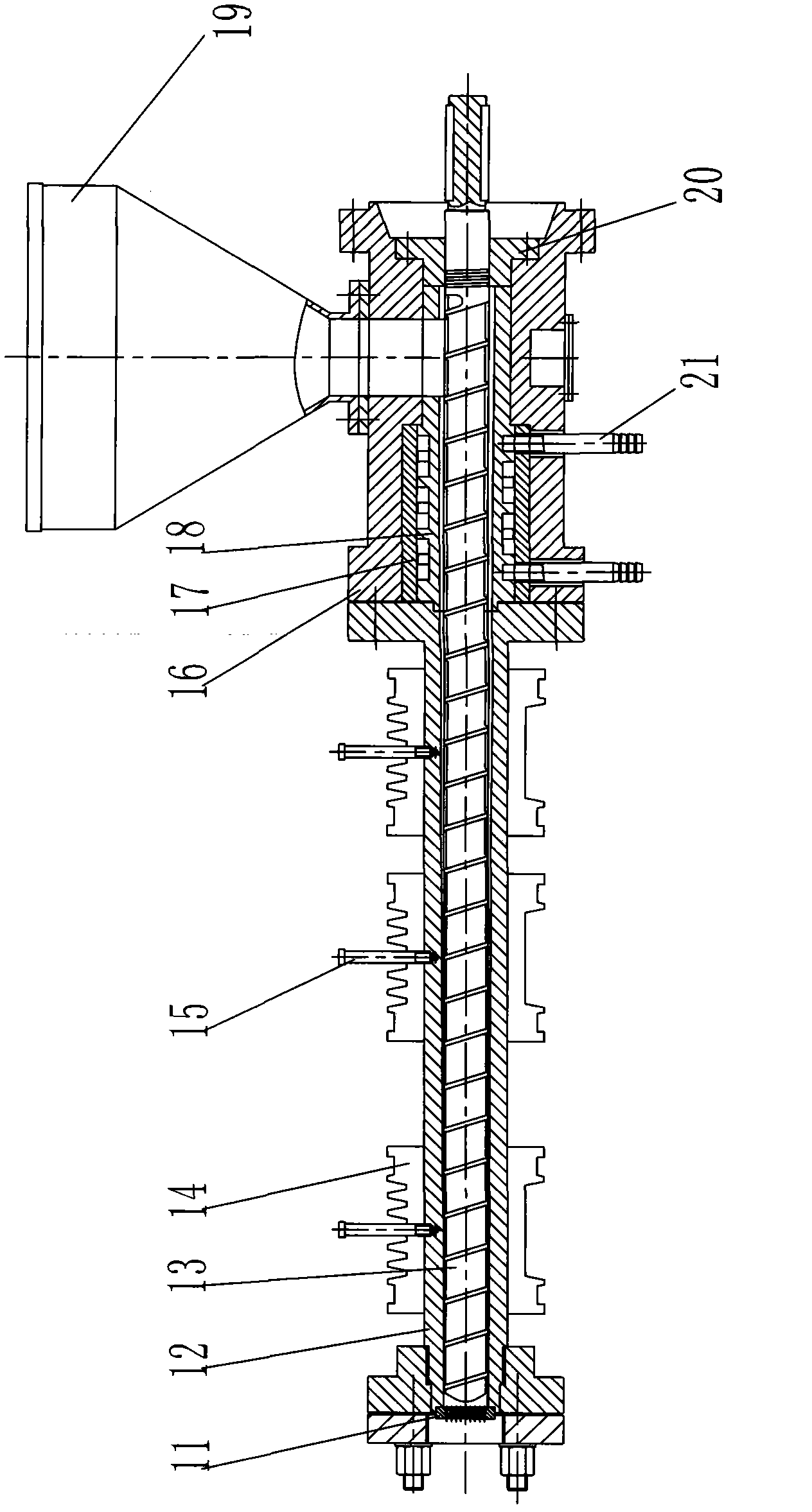

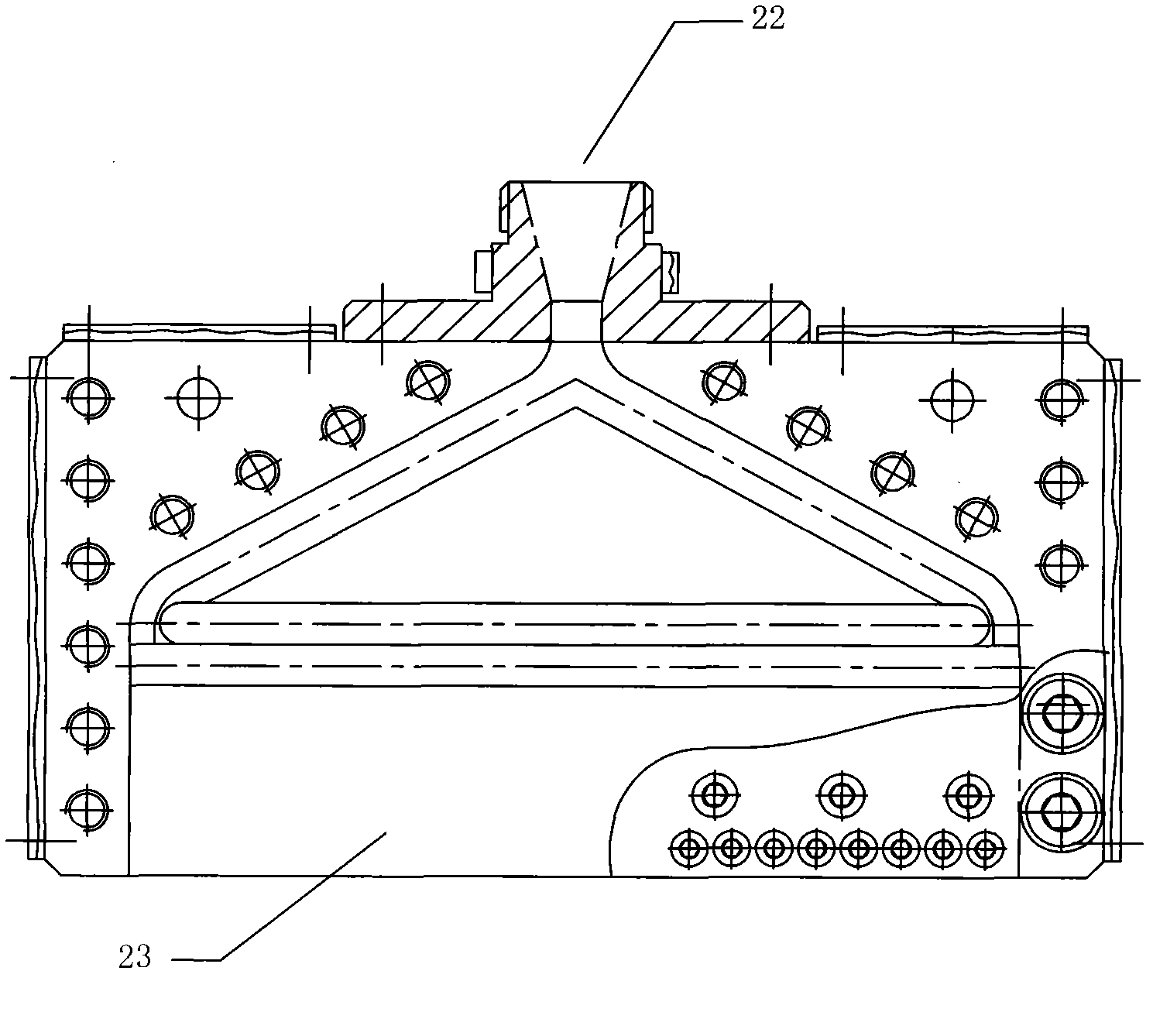

[0033] Such as figure 1As shown, the preparation device for the implementation of the ultra-high molecular weight polyethylene sheet includes an extruder 1, a sheet die 2 and a stretching device, and the sheet die 2 is located between the extruder 1 and the stretching device; The stretching equipment includes a heating equipment 6 and a main stretching machine 8 (nine-roll stretching machine), and the heating equipment 6 is located between the plate molds 2 of the main stretching machine 8, and in the heating equipment 6 Auxiliary stretching machine 7 (seven-roll stretching machine) is also installed; stretching is multi-stage stretching, which can be two-stage, or three-stage, or four-stage stretching, etc.; stretching machine can be seven-roll stretching machine , nine-roll stretching machine, or other types of stretching machines. A calender 3, a first tractor 4, and a conveyor 5 are installed between the plate mold 2 and the heating device 6, and the first tractor 4 is lo...

Embodiment 2

[0037] Utilize the preparation method of the ultra-high molecular weight polyethylene sheet of preparation device described in embodiment 1, comprises the steps:

[0038] (a) Material preparation: Add ultra-high molecular weight polyethylene powder with a viscosity average molecular weight of 3 million, nano-montmorillonite, coupling agent, antioxidant and flow modifier into a high-speed mixer for uniform mixing, coupling The agent is silane coupling agent KH550, the antioxidant is B215, and the flow modifier is polyethylene wax. The weight ratio of each component is: ultra-high molecular weight polyethylene powder is 100 parts, nano-montmorillonite is 20 parts, The coupling agent KH550 is 0.2 parts, the antioxidant B215 is 0.5 parts, and the polyethylene wax is 1 part;

[0039] (b) material extruding: the material obtained after mixing in step (a) is joined in the screw extruder and carries out melt extruding, and the diameter of the screw rod (13) of screw extruder is 150 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line speed | aaaaa | aaaaa |

| Line speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com