Polyacrylonitrile polymer, process for production of the polymer, process for production of precursor fiber for carbon fiber, carbon fiber, and process for production of the carbon fiber

A technology of polyacrylonitrile and manufacturing method, which is applied in the field of carbon fiber precursor fiber and carbon fiber manufacturing, can solve the problems of low tensile level and small improvement effect of tensile modulus of elasticity, etc., and achieves excellent tensile strength and quality, and production Excellent performance in durability and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

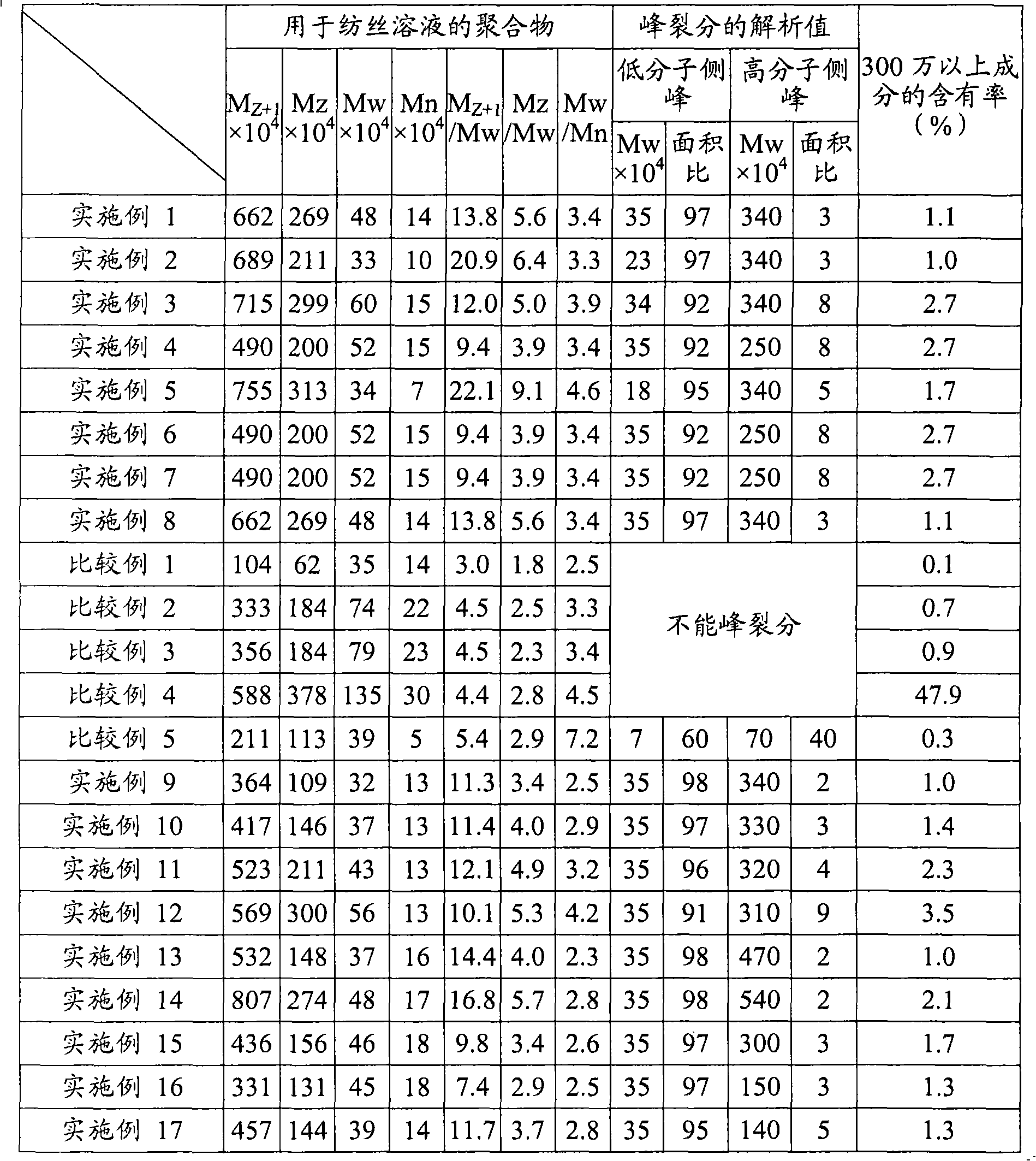

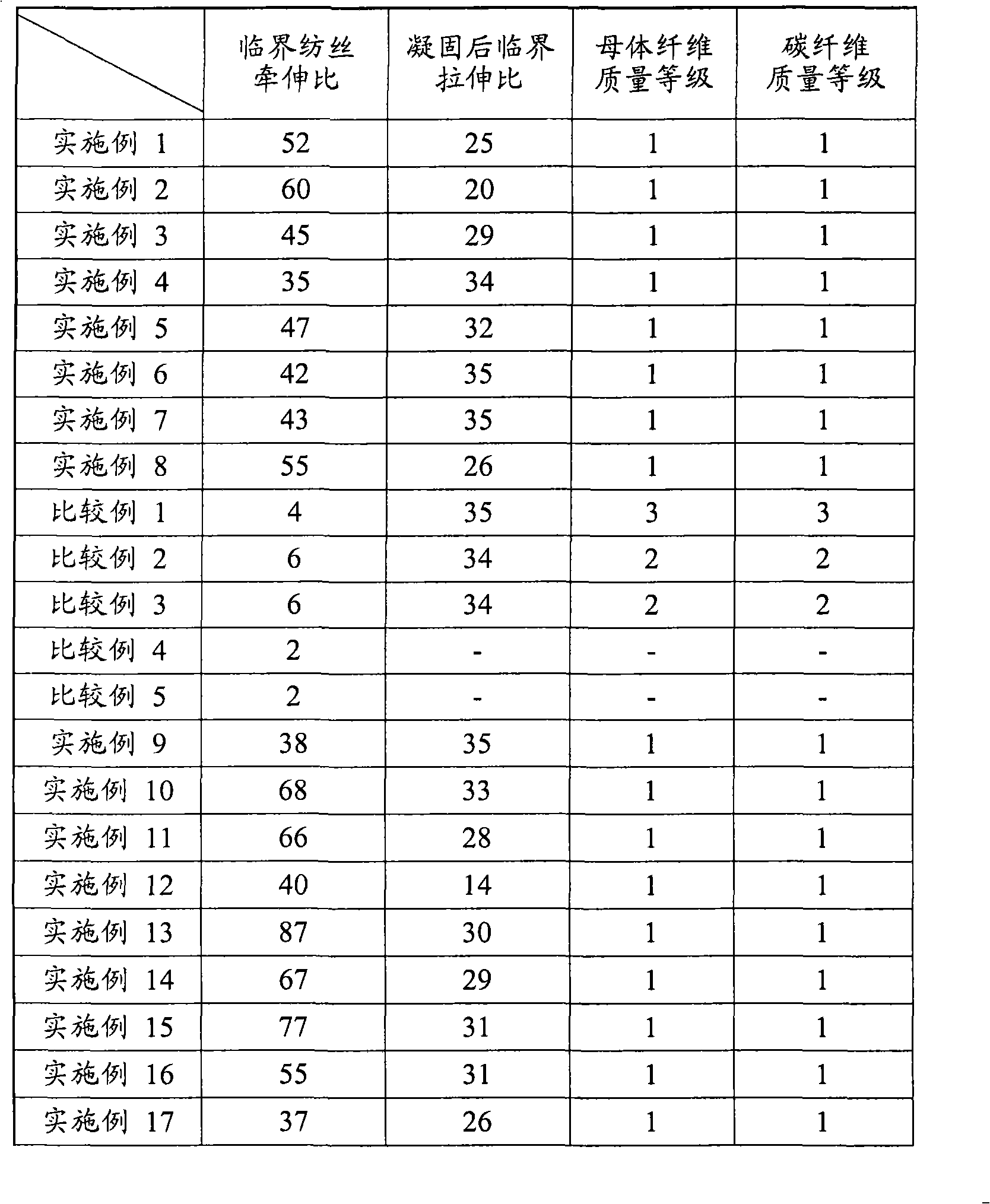

Examples

Embodiment 1

[0246] 100 parts by weight of AN, 0.01 parts by weight of 2,2'-azobisisobutyronitrile (hereinafter sometimes abbreviated as AIBN) as a radical initiator, 1.5 parts by weight of partially saponified polyvinyl alcohol (polymerization degree 1000), and 290 parts by weight of water were mixed and put into a reaction vessel equipped with a reflux pipe and stirring blades. After replacing the space in the reaction vessel with nitrogen, heat treatment under the following conditions (referred to as polymerization condition A.) was carried out while stirring, and polymerization was carried out by aqueous suspension polymerization to obtain a PAN-based polymer.

[0247] (1) Heating from 30°C to 70°C (heating rate 120°C / hour)

[0248] (2) Keep at 70°C for 2 hours

[0249] The obtained PAN-based polymer powder was sufficiently washed with water and dried to obtain dry polymer A. Mz, Mw, and Mn of the obtained dry polymer A were 5.8 million, 3.4 million, and 1.4 million, respectively.

...

Embodiment 2

[0260] 3 parts by weight of dry polymer A obtained in Example 1 are uniformly dissolved in 270 parts by weight of dimethyl sulfoxide, and then mixed with 100 parts by weight of AN, 1 part by weight of itaconic acid, and 0.4 parts by weight as a free radical initiator 2,2'-Azobisisobutyronitrile and 0.3 parts by weight of n-octyl mercaptan as a chain transfer agent were uniformly dissolved and put into a reaction vessel equipped with a reflux tube and stirring blades. After the space in the reaction vessel was replaced with nitrogen, the above-mentioned polymerization condition B was heat-treated while stirring, and polymerized by the solution polymerization method to obtain a PAN-based polymer solution.

[0261] After adjusting the obtained PAN-based polymer solution to have a polymer concentration of 25% by weight, ammonia gas was blown in to pH 8.5 to neutralize itaconic acid and simultaneously introduce ammonium groups into the PAN-based polymer to prepare a spinning solutio...

Embodiment 3

[0263] 8 parts by weight of dry polymer A obtained in Example 1 are uniformly dissolved in 410 parts by weight of dimethyl sulfoxide, and then mixed with 100 parts by weight of AN, 1 part by weight of itaconic acid, and 0.4 parts by weight as a free radical initiator 2,2'-Azobisisobutyronitrile and 0.1 parts by weight of n-octyl mercaptan as a chain transfer agent were uniformly dissolved, and put into a reaction vessel equipped with a reflux tube and a stirring blade. After the space in the reaction vessel was replaced with nitrogen, heat treatment under the polymerization condition B was carried out while stirring, and polymerization was carried out by the solution polymerization method to obtain a PAN-based polymer solution.

[0264] After adjusting the obtained PAN-based polymer solution to a polymer concentration of 18% by weight, ammonia gas was blown in to pH 8.5 to neutralize itaconic acid and simultaneously introduce ammonium groups into the polymer to prepare a spinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com