Composition, resin material, and method for producing same

A technology of composition and compound, which is applied in the field of resin material and its preparation and composition, can solve problems such as difficulty in popularization and use, poor process adaptability, inability to realize continuous automatic production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

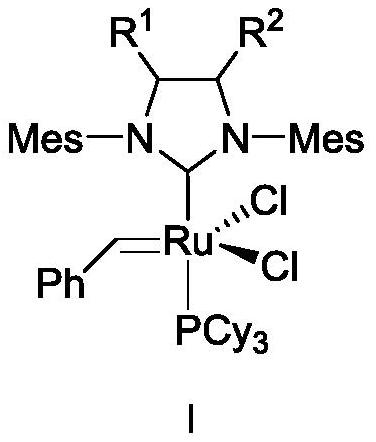

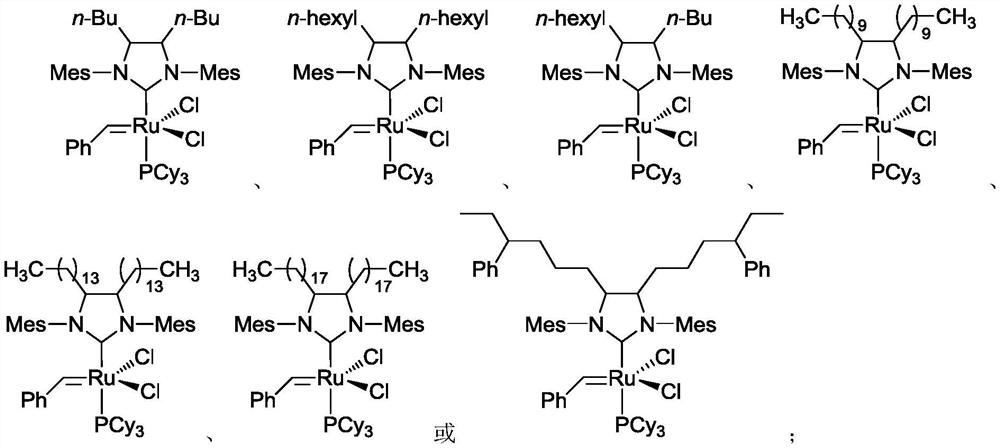

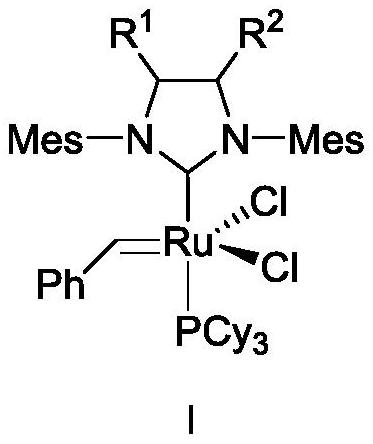

[0126] Embodiment 1: Catalyst 1,3-bis(2,4,6-trimethylphenyl)-2-(4,5-dibutylimidazolidinylidene) (dichlorobenzylidene) containing butyl substituent base) (tricyclohexylphosphine) ruthenium (I-1) synthesis

[0127] The synthesis of butyl substituent catalyst I-1 comprises the following steps:

[0128] 1) Preparation of N,N'-bis(2,4,6-trimethyl)phenylethylenediimine (9)

[0129]

[0130] Add 3.73 mL of glyoxal (8) aqueous solution (40%) and 80 mL of methanol successively into a 500 mL three-neck flask equipped with a dropping funnel, and stir to dissolve the glyoxal. Add 9.12 mL of m-trimethylaniline (7) and 10 mL of methanol to the dropping funnel, and slowly drop them into the flask. The temperature of the reaction solution was controlled at about 22° C., and stirred for 12 hours. During this process, a bright yellow precipitate slowly precipitated from the reaction solution. After the reaction, the reaction liquid was filtered to obtain a yellow solid, which was washed ...

Embodiment 2

[0140] Embodiment 2: Containing hexyl substituent catalyst 1,3-bis(2,4,6-trimethylphenyl)-2-(4,5-dihexyl imidazolidinylidene) (dichlorobenzylidene) Synthesis of (Tricyclohexylphosphine)ruthenium(I-2)

[0141] Containing the synthesis of hexyl substituent catalyst 1-2 comprises the following steps:

[0142] 1) Preparation of N,N'-bis(2,4,6-trimethyl)phenylethylenediimine (9)

[0143]

[0144] Add 3.73 mL of glyoxal (8) aqueous solution (40%) and 80 mL of methanol successively into a 500 mL three-neck flask equipped with a dropping funnel, and stir to dissolve the glyoxal. Add 9.12 mL of m-trimethylaniline (7) and 10 mL of methanol to the dropping funnel, and slowly drop them into the flask. The temperature of the reaction solution was controlled at about 22° C., and stirred for 12 hours. During this process, a bright yellow precipitate slowly precipitated from the reaction solution. After the reaction, the reaction liquid was filtered to obtain a yellow solid, which was ...

Embodiment 3

[0154] Example 3: 4-butyl-5-hexyl-1,3-bis(2,4,6-trimethylphenyl)-2-(imidazolidinylidene)(benzylidene)(tricyclohexyl Preparation of phosphine) ruthenium(I-3) dichloride

[0155] 1.1) Preparation of N,N'-bis(2,4,6trimethylphenyl)dodecane-5,6-diamine (14)

[0156]

[0157] Under nitrogen protection, add 2.92g N,N'-bis(2,4,6-trimethyl)phenylethylenediimine (9) (Mw: 292.46g / mol; 10.0 mmol), 100mL tetrahydrofuran was stirred to dissolve it. Then, the ampoule was placed in an ethanol cold bath at -78°C, stirred and cooled. After the reaction solution was fully cooled, 4.17 mL (10.0 mmol) of hexyllithium (2.4 M solution in toluene) was slowly added dropwise with a syringe. The reaction solution was cooled to -78°C again, and 6.25 mL (10.0 mmol) of butyllithium (1.6 M hexane solution) solution was slowly added dropwise with a syringe. After the addition was complete, the reaction mixture was slowly raised to room temperature with stirring, and continued to stir for 0.5 h. Then,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com