Flexible polypropylene with high impact strength

A technology of impact strength and polypropylene composition, applied in the field of polypropylene composition, can solve the problem of lowering the melting point of polypropylene composition, and achieve the effects of reduced shrinkage, high flexibility and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

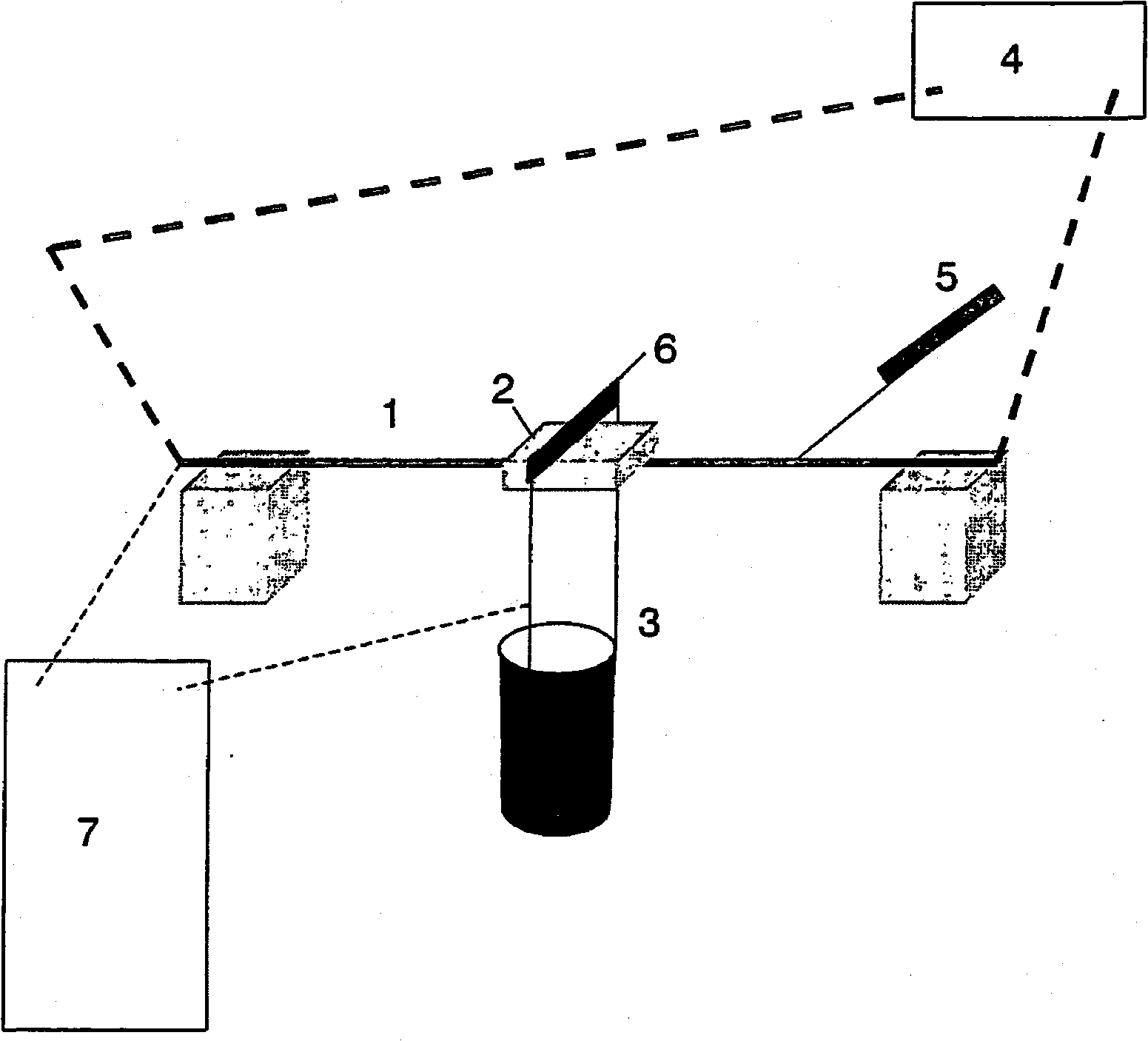

Method used

Image

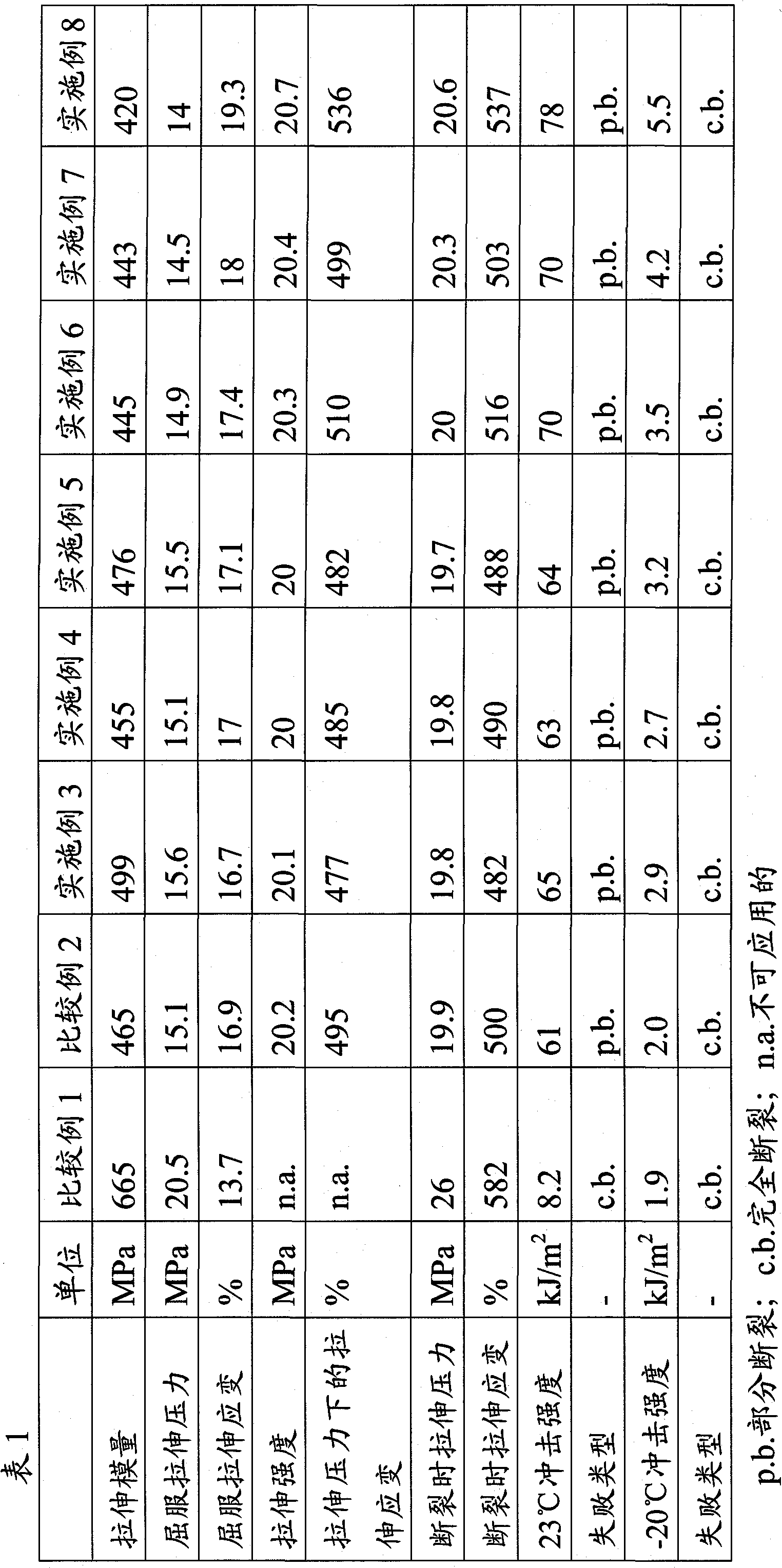

Examples

Embodiment

[0169] 1. Materials

[0170] Compound:

[0171] Silicon group-containing polymer (example of component (B) in the first and second embodiments)

[0172] For cable insulators, high-voltage low-density ethylene terpolymer (LE4481), wherein the content of vinyltrimethylsilane is 1.75wt.%, and the content of butyl acrylate is about 17wt.%. The MFR of the cable insulator 2 (190℃ / 2.16kg) is 5g / 10min, the density is 927kg / m 3 , available from Borealis Polyolefine GmbH.

[0173] Propylene polymer 1 (PP1) (example of matrix phase (A) in the first embodiment)

[0174] As known in the art, polypropylene resin PP1 is a homogeneous-random-heterophase polypropylene copolymer composition prepared by a multi-stage polymerization process consisting of a loop reactor and two gas phase reactors using A conventional heterogeneous Ziegler-Natta catalyst system consisting of MgCl 2 -Supported TiCl 4 Catalyst and internal electron donor, triethylaluminum as cocatalyst and organosilane as externa...

Embodiment 3

[0188] 98.9wt.% of PP1 is used as matrix phase, with 0.95wt.% of silicon group-containing polymer (LE4481), 0.05wt.% of catalyst masterbatch CAT-MB50 and 0.1wt.% of Irganox B225 (available from Ciba )use together.

Embodiment 4

[0190] 97.9 wt.% PP1 was used as matrix phase together with 2 wt.% polymer containing silicon groups (LE4481) and 0.1 wt.% Irganox B225 (from Ciba).

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com