Improved crosslinked polyvinyl chloride structural foam and preparation method thereof

A technology for cross-linking polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of cross-linking polyvinyl chloride structural foam and its preparation, can solve the problems of limiting the control range of process parameters, reducing the acidity of the reaction environment, increasing the difficulty of process control, and the like. Shortened process time, simple manufacturing process control, and small dimensional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

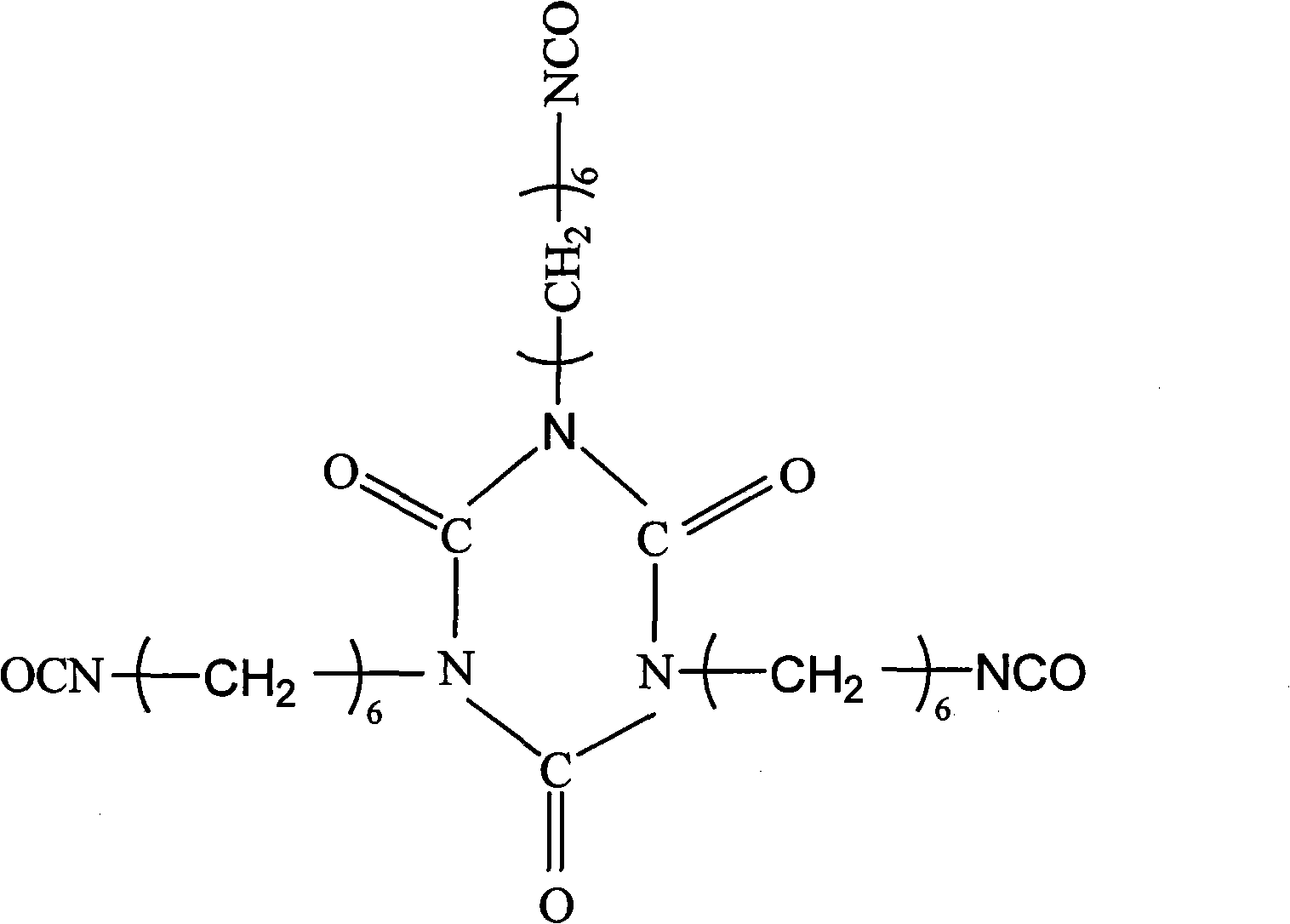

Method used

Image

Examples

Embodiment 1

[0047] The mixture contains 100 kg of polyvinyl chloride, 66 kg of liquefied diphenylmethane-4,4'-diisocyanate, 12.6 kg of polymethylene polyphenyl polyisocyanate, 1.6 kg of epoxidized soybean oil, and azobisisobutyronitrile 7.0 kg, 1.8 kg of azodicarbonamide, 3.0 kg of melamine, 20.6 kg of methyl hexahydrophthalic anhydride, and 1.2 kg of surfactant. Stir and mix in a mixer until uniform to obtain a paste mixture with a certain viscosity.

[0048] Pour the product into a steel mold with a thickness of 28mm to fill the mold. It is placed between the press plates at 175°C and heated at a pressure of 14MPa. The mixture was cooled to room temperature under pressure and removed to give a cooled semi-foamed molding.

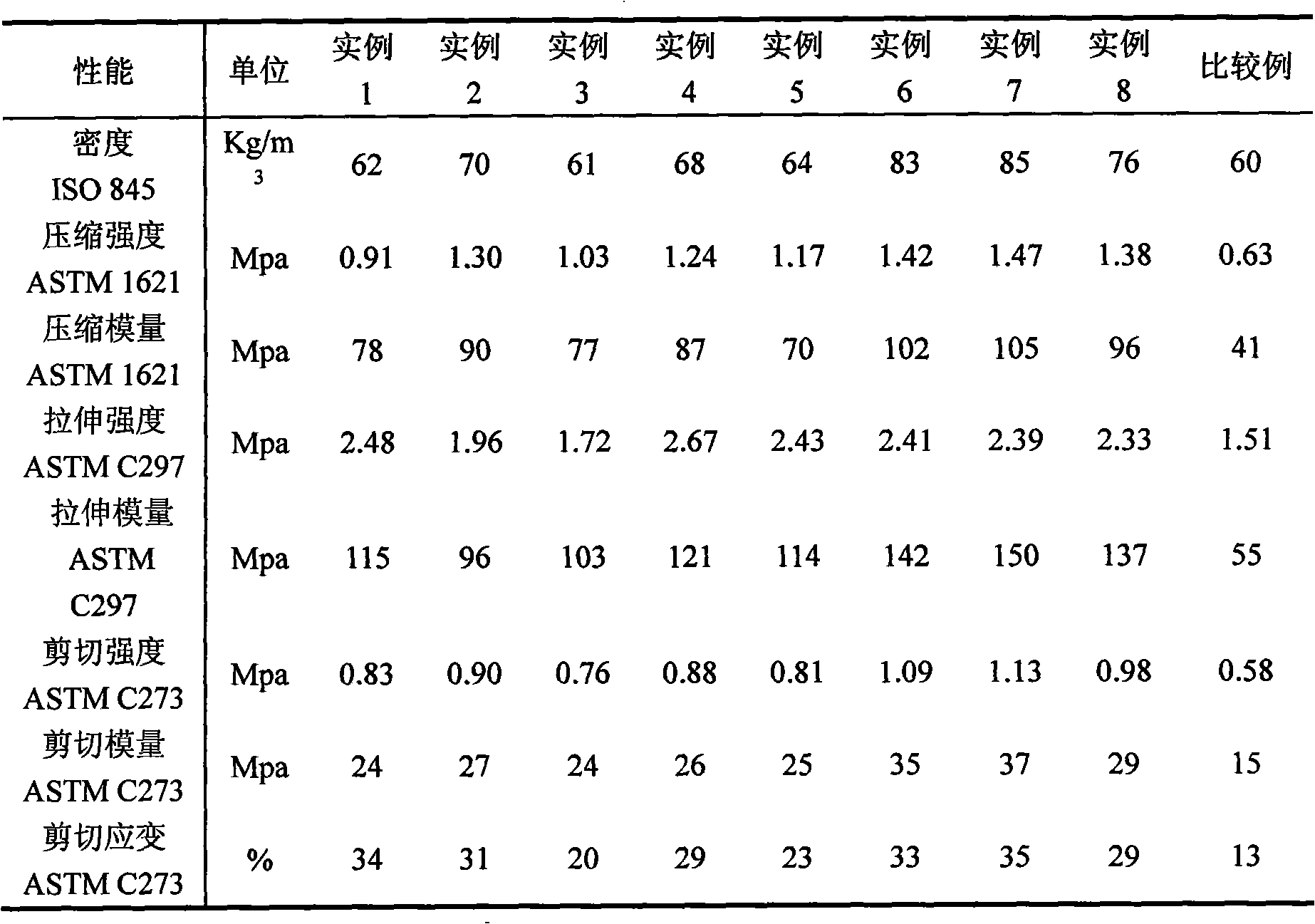

[0049] Next, place the semi-foamed molded object in a steam oven to expand for 6 hours, and the steam temperature is 93°C±2°C. After cooling, solidify and post-treat in a steam oven at 65°C for 5 days to fully react the isocyanate, thereby obtaining a rigid foam pr...

Embodiment 2

[0051] The mixture contains 100 kg of polyvinyl chloride, 88 kg of liquefied diphenylmethane-4,4'-diisocyanate, 8.6 kg of polymethylene polyphenyl polyisocyanate, 1.0 kg of epoxidized soybean oil, and azobisisobutyronitrile 8.2 kg, 1.1 kg of azodicarbonamide, 5 kg of melamine, 10 kg of methyl hexahydrophthalic anhydride, and 2.1 kg of surfactant. Stir and mix in a mixer until uniform to obtain a paste mixture with a certain viscosity.

[0052] Pour the product into a steel mold with a thickness of 28mm to fill the mold. Place it into a press plate at 175° C. and heat it at a pressure of 15 MPa. The mixture was cooled to room temperature under pressure and removed to give a cooled semi-foamed molding.

[0053] Next, place the semi-foamed molded object in a steam oven to expand for 6 hours, and the steam temperature is 96°C±2°C. After cooling, spray and solidify with hot water at 65°C for 5 days to fully react the isocyanate, thereby obtaining a rigid foam product with a dens...

Embodiment 3

[0055] The mixture contains 100 kg of polyvinyl chloride, 30 kg of polymethylene polyphenyl polyisocyanate, 29 kg of liquefied diphenylmethane diisocyanate, 1.5 kg of epoxy soybean oil, 6.6 kg of azobisisobutyronitrile, azobis Formamide 1.5 kg, melamine 3.0 kg, phthalic anhydride 19.4 kg. Stir and mix in a mixer until uniform to obtain a paste mixture with a certain viscosity.

[0056] Pour the product into an aluminum mold with a thickness of 28mm, filling the mold. It is placed between the press plates at 165°C and heated at a pressure of 12MPa. The mixture was cooled to room temperature under pressure and removed to give a cooled semi-foamed molding.

[0057] Next, place the semi-foamed molded object in a steam oven for expansion for 4 hours, and the steam temperature is 97°C±2°C. After cooling, solidify and post-treat in a steam oven at 60°C for 9 days to fully react the isocyanate, thereby obtaining a rigid foam product with a density of 61kg / m 3 . Its mechanical pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com