Polyacrylonitrile-based graphite fiber and preparation method thereof

A polyacrylonitrile-based, graphite fiber technology, applied in the field of fibers, can solve the problems of not being able to meet the high strength, high modulus mechanical performance indicators, low mechanical properties, and carbon fiber mechanical properties. Tensile strength decreased, etc., to achieve excellent dimensional stability. , The effect of low thermal expansion coefficient and tensile strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the above-mentioned polyacrylonitrile-based graphite fiber comprises the following steps: the raw silk is sequentially passed through an oxidation furnace, a low-temperature carbonization furnace, a high-temperature carbonization furnace, a graphitization furnace, electrolyte treatment, water washing, a drying furnace body 1, sizing, and a drying furnace body 2. Finally, the yarn is collected; each process section of the whole line is given proper drafting, which is realized through the transmission of the frequency conversion drafting machine. Continuous mass production can be realized; 5-100 bundles of raw silk can be run at the same time.

[0040] Specifically, the detailed preparation steps are as follows:

[0041] 1) Pre-oxidation: pre-oxidize the raw silk to obtain pre-oxidized fiber body.

[0042] In the pre-oxidation step, the raw silk is sequentially subjected to pre-oxidation treatment through 4 to 6 oxidation temperature zones; wher...

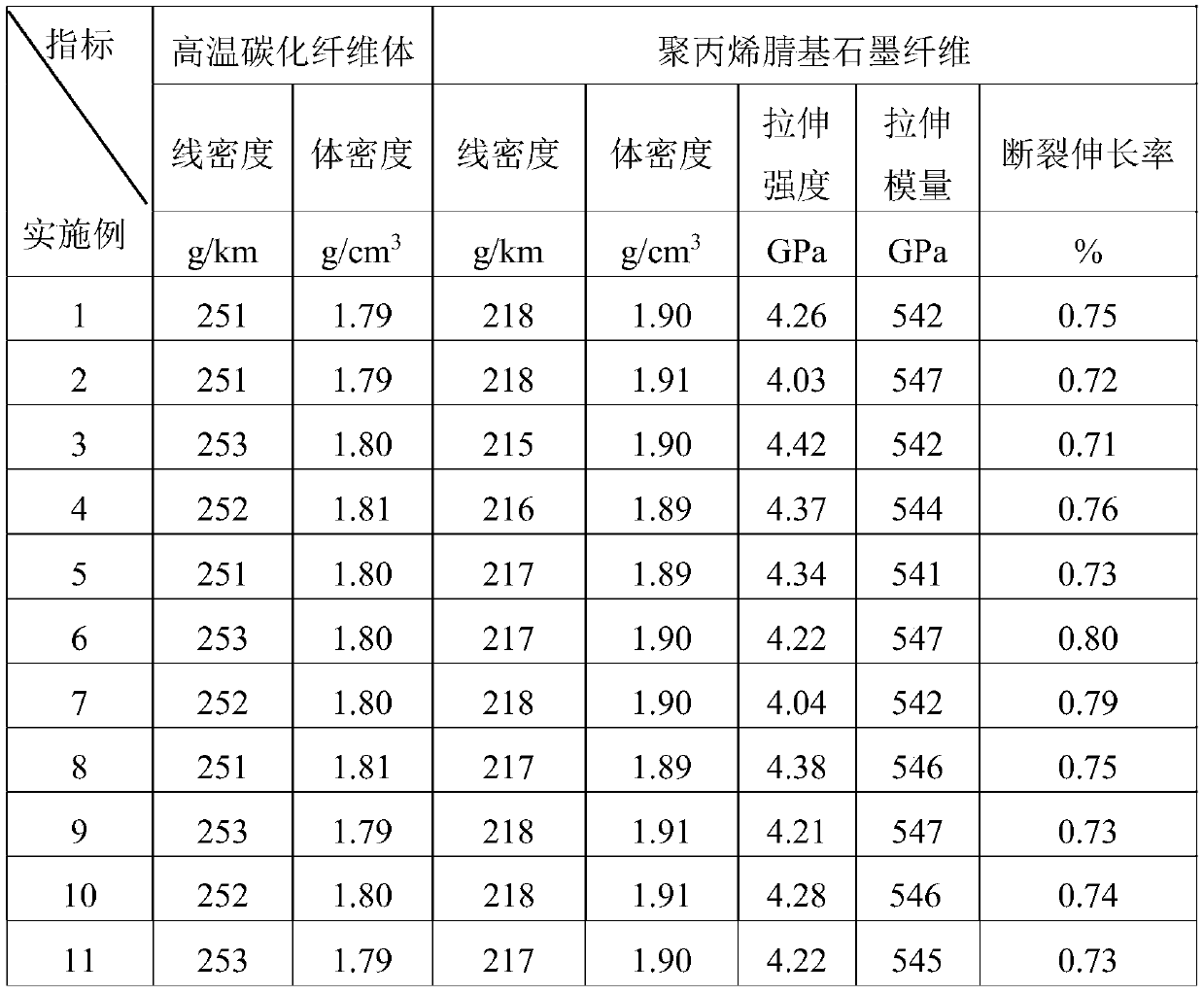

Embodiment 1

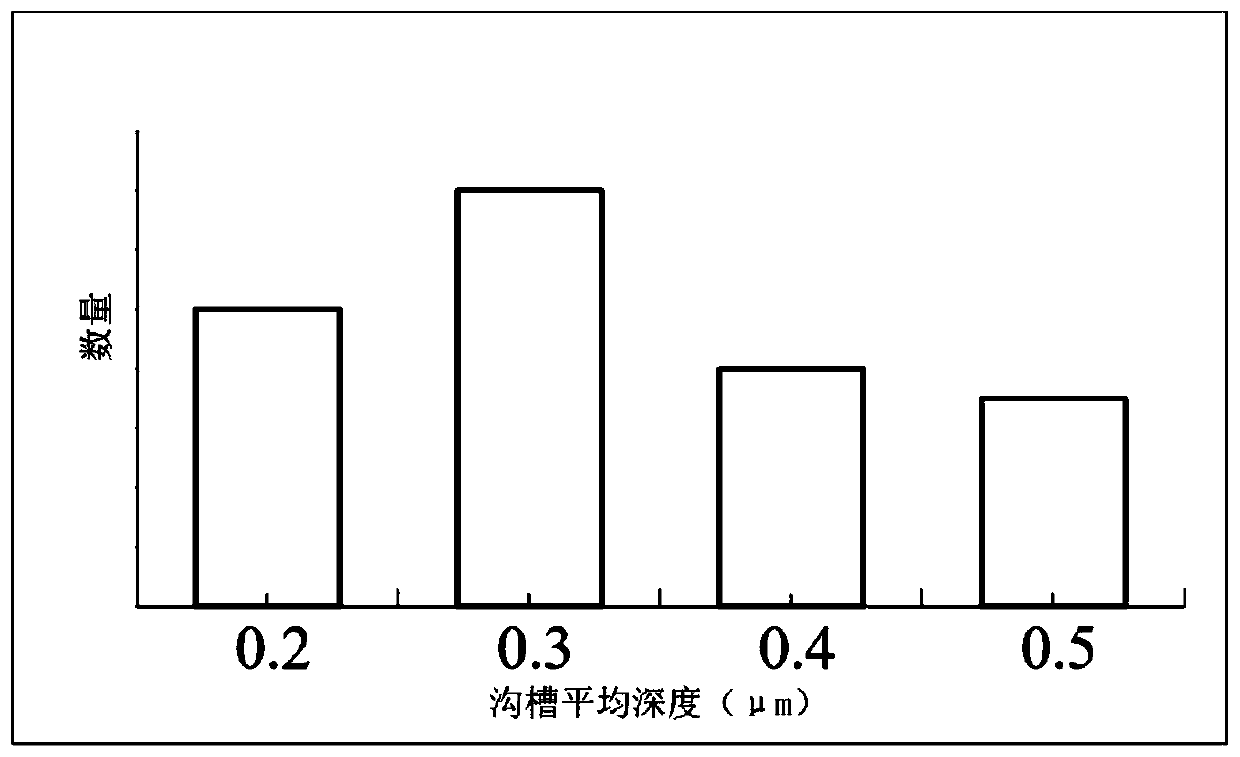

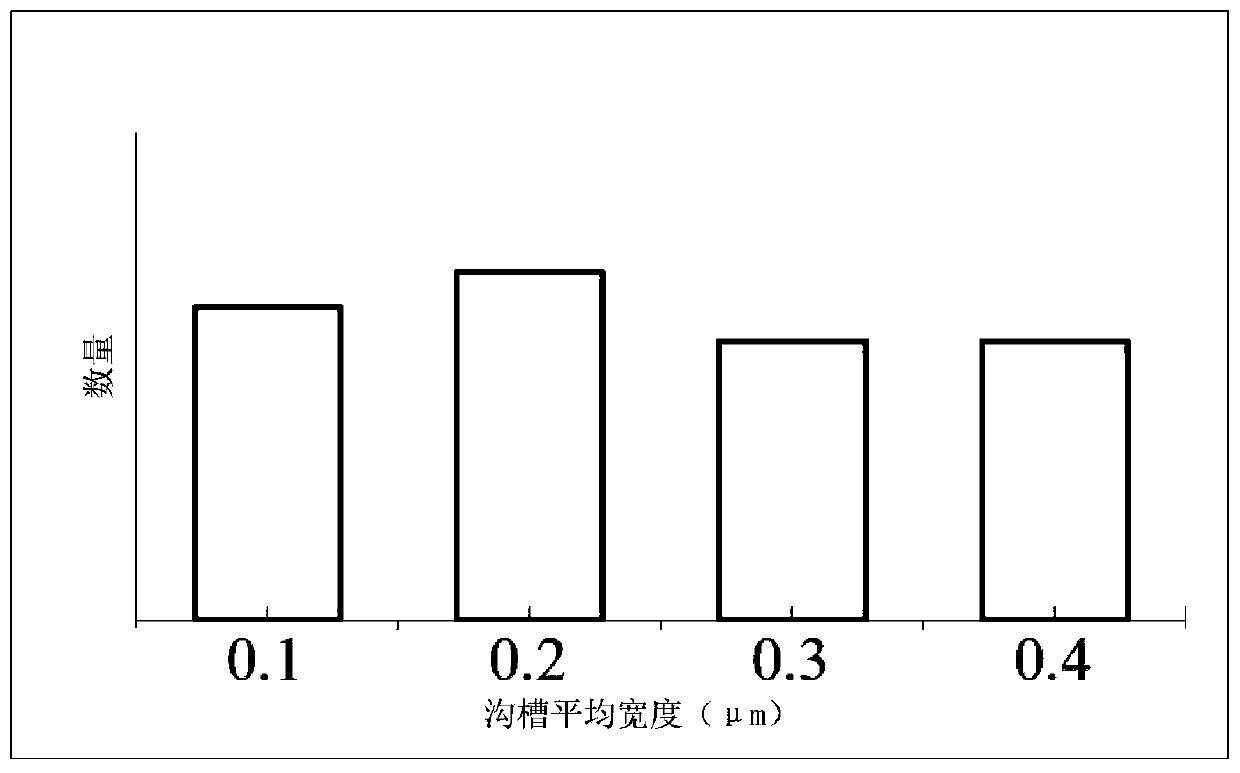

[0098] Choose a diameter of 9.0μm and a bulk density of 1.181g / cm 3 6K polyacrylonitrile fiber precursors with a linear density of 510g / Km, an average groove depth of 0.2 μm, an average width of 0.4 μm, and an average surface roughness Ra of 0.0182 μm;

[0099] The raw silk goes through oxidation furnace, low-temperature carbonization furnace, high-temperature carbonization furnace, graphitization furnace, electrolyte treatment, water washing, drying furnace body 1, sizing, drying furnace body 2, and finally winding and forming. Proper drafting is given to each process section of the whole line, which is realized through the transmission of the frequency conversion drafting machine. Specific steps are as follows:

[0100] 1) Pre-oxidation: Pre-oxidized fibers are obtained by making the precursor enter the first oxidation temperature zone of 195°C, the second oxidation temperature zone of 215°C, the third oxidation temperature zone of 227°C and the fourth oxidation temperature...

Embodiment 2

[0115] Choose a diameter of 9.0μm and a bulk density of 1.181g / cm 3 6K polyacrylonitrile fiber precursors with a linear density of 510g / Km, an average groove depth of 0.5 μm, an average width of 0.4 μm, and an average surface roughness Ra of 0.0194 μm;

[0116] The raw silk goes through oxidation furnace, low-temperature carbonization furnace, high-temperature carbonization furnace, graphitization furnace, electrolyte treatment, water washing, drying furnace body 1, sizing, drying furnace body 2, and finally winding and forming. Proper drafting is given to each process section of the whole line, which is realized through the transmission of the frequency conversion drafting machine. Specific steps are as follows:

[0117] 1) Pre-oxidation: Pre-oxidized fibers are obtained by making the precursor enter the first oxidation temperature zone of 195°C, the second oxidation temperature zone of 215°C, the third oxidation temperature zone of 227°C and the fourth oxidation temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com