Methods for synthesizing, recycling and reprocessing recyclable shape memory thermosetting resin

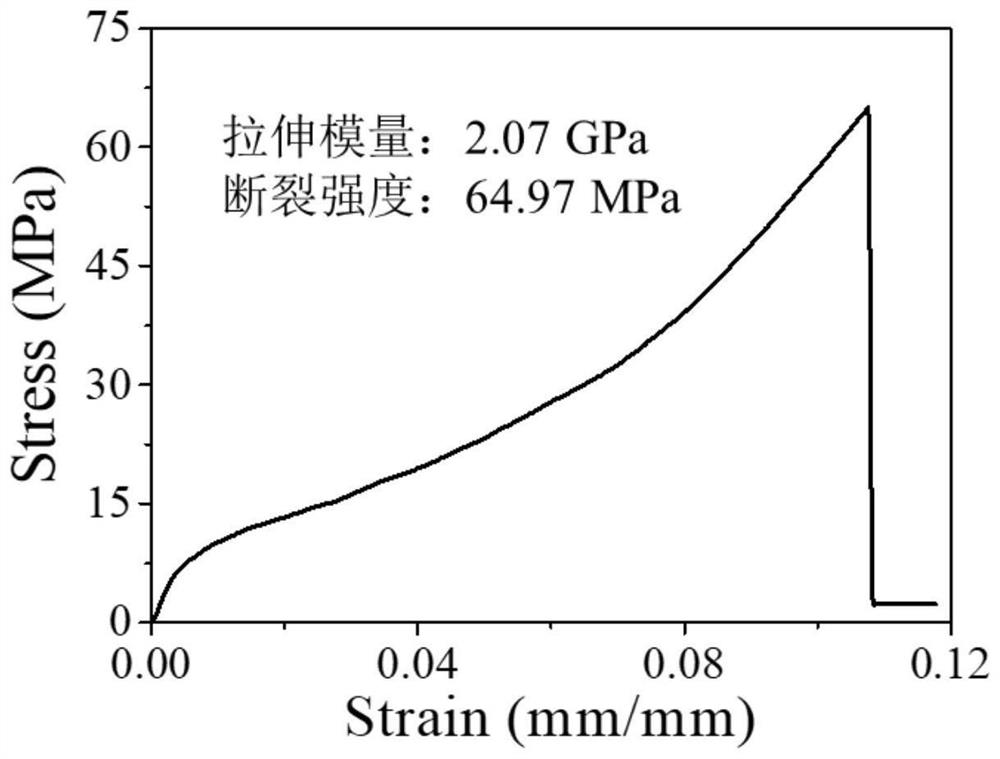

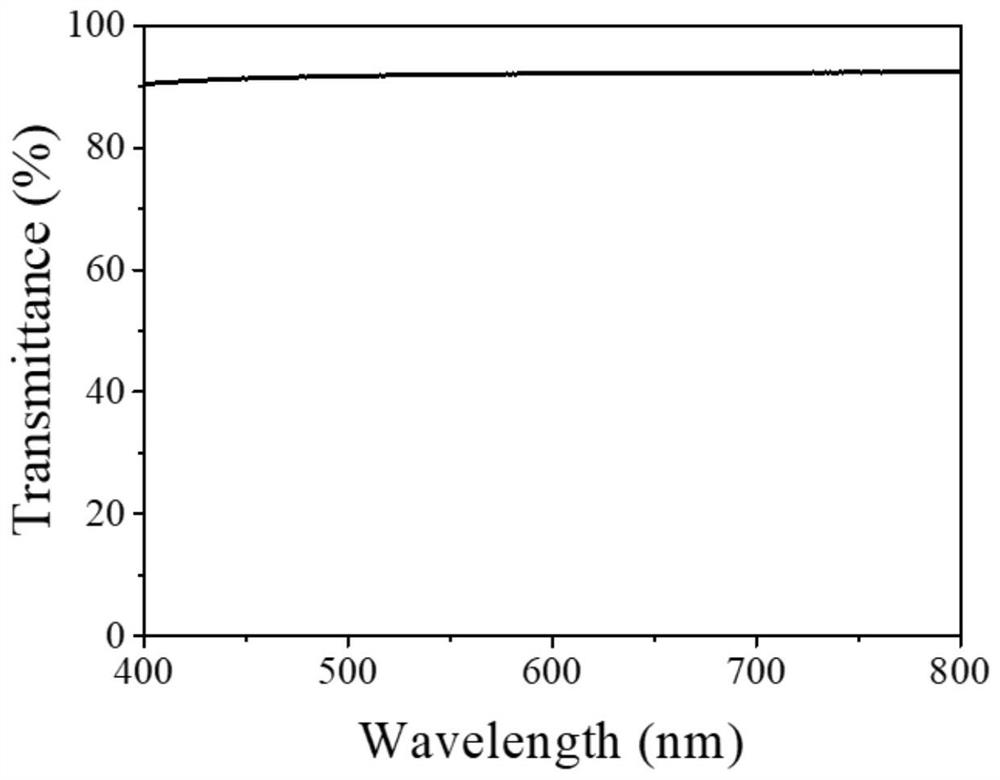

A thermosetting and memory technology, which is applied in the field of new polymer material synthesis, can solve the problems of harshness, weak reversibility, rare and expensive raw material recovery conditions, etc., and achieve the effects of excellent mechanical properties, cheap and easy-to-obtain reagents, and excellent tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Trimethylolpropane tris(3-mercaptopropionate) is used as polythiol, 1,3-bis(1-isocyanato-1-methylethyl)benzene is used as dibasic isocyanate, and N,N - Diisopropylethylamine as a catalyst as an example.

[0058] A recyclable shape-memory polythiourethane thermosetting resin comprising trimethylolpropane tris(3-mercaptopropionate) and 1,3-bis(1-isocyanato-1-methylethyl ) The reaction product of benzene component, the structure of described polythiourethane is:

[0059]

[0060] The synthetic method of above-mentioned recyclable shape-memory polythiourethane thermosetting resin comprises the steps:

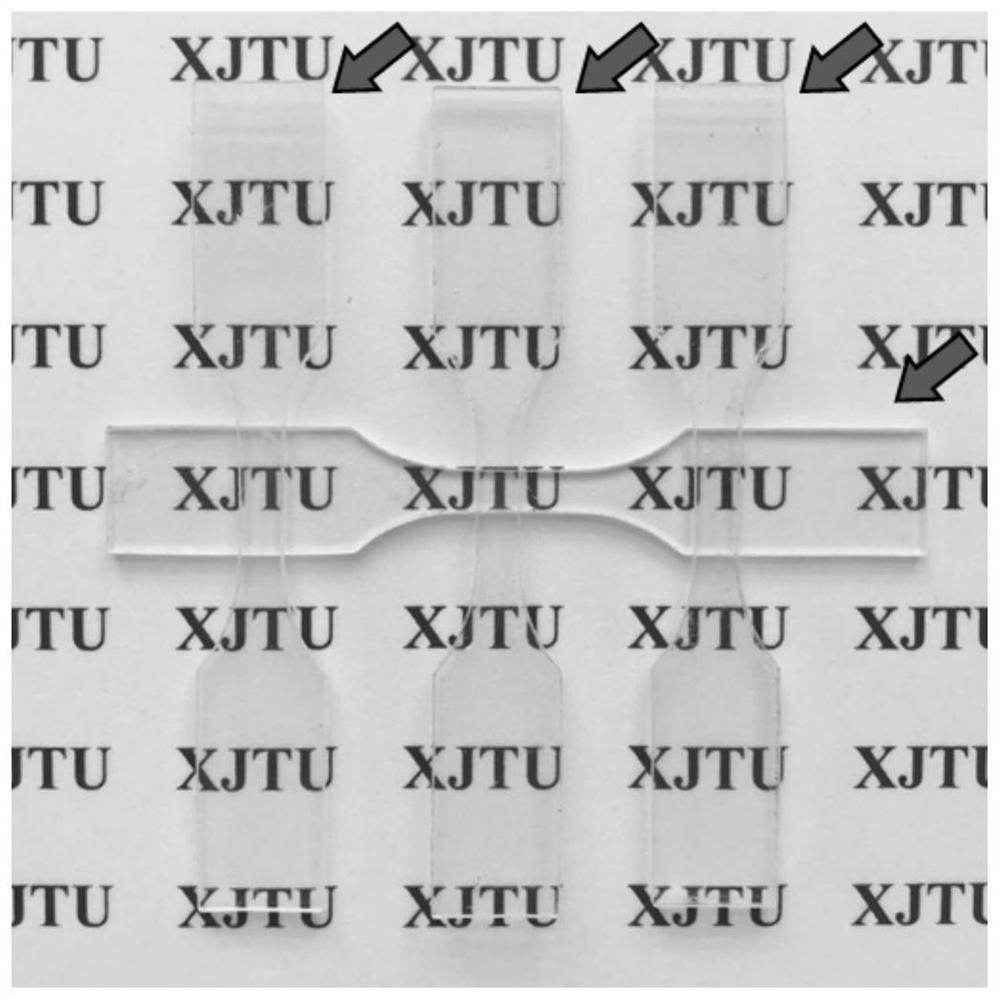

[0061] Add 20.84 g of trimethylolpropane tris(3-mercaptopropionate) and 19.16 g of 1,3-bis(1-isocyanato-1-methylethyl)benzene into a beaker equipped with a stirring bar , after mixing evenly, add 40 mg of N,N-diisopropylethylamine and stir evenly, pour the mixture into a polytetrafluoroethylene mold, react at room temperature for 2 hours, and peel the material from the m...

Embodiment 2

[0063] Use trimethylolpropane tris(3-mercaptopropionate) as polythiol, 4,4'-dicyclohexylmethane diisocyanate as diisocyanate, and N,N-diisopropylethylamine as catalyst as an example.

[0064] A recyclable shape-memory polythiourethane thermosetting resin, which is a reaction product comprising trimethylolpropane tris(3-mercaptopropionate) and 4,4'-dicyclohexylmethane diisocyanate components, the The structure of polythiourethane is:

[0065]

[0066] The synthetic method of above-mentioned recyclable shape-memory polythiourethane thermosetting resin comprises the steps:

[0067] Add 31.88g of trimethylolpropane tris(3-mercaptopropionate) and 31.48g of 4,4'-dicyclohexylmethane diisocyanate into a beaker equipped with a stirring bar, mix well, then add 63mg of N , Stir N-diisopropylethylamine evenly, pour the mixture into a polytetrafluoroethylene mold, react at room temperature for 2 hours, peel the material from the mold, and obtain high-strength, colorless and transparen...

Embodiment 3

[0069] Trimethylolpropane tris(3-mercaptopropionate) is used as polythiol, isophorone diisocyanate is used as dibasic isocyanate, and N,N-diisopropylethylamine is used as a catalyst.

[0070] A recyclable shape-memory polythiourethane thermosetting resin, which is a reaction product comprising trimethylolpropane tris (3-mercaptopropionate) and isophorone diisocyanate components, the polythiourethane The structure is:

[0071]

[0072] The synthetic method of above-mentioned recyclable shape-memory polythiourethane thermosetting resin comprises the steps:

[0073] Add 20.84g of trimethylolpropane tris(3-mercaptopropionate) and 17.44g of isophorone diisocyanate into a beaker equipped with a stirring bar. After mixing evenly, add 38mg of N,N-diisocyanate Stir the propylethylamine evenly, pour the mixed solution into a polytetrafluoroethylene mold, react at room temperature for 2 hours, and peel the material from the mold to obtain a high-strength, colorless and transparent sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com