Photosensitive resin based on vegetable oil and citric acid as well as preparation method and application thereof

A photosensitive resin and vegetable oil technology, applied in the preparation of organic compounds, the preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of low functionality, low bio-based content, insufficient rigidity, etc. The effect of high bio-based content, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

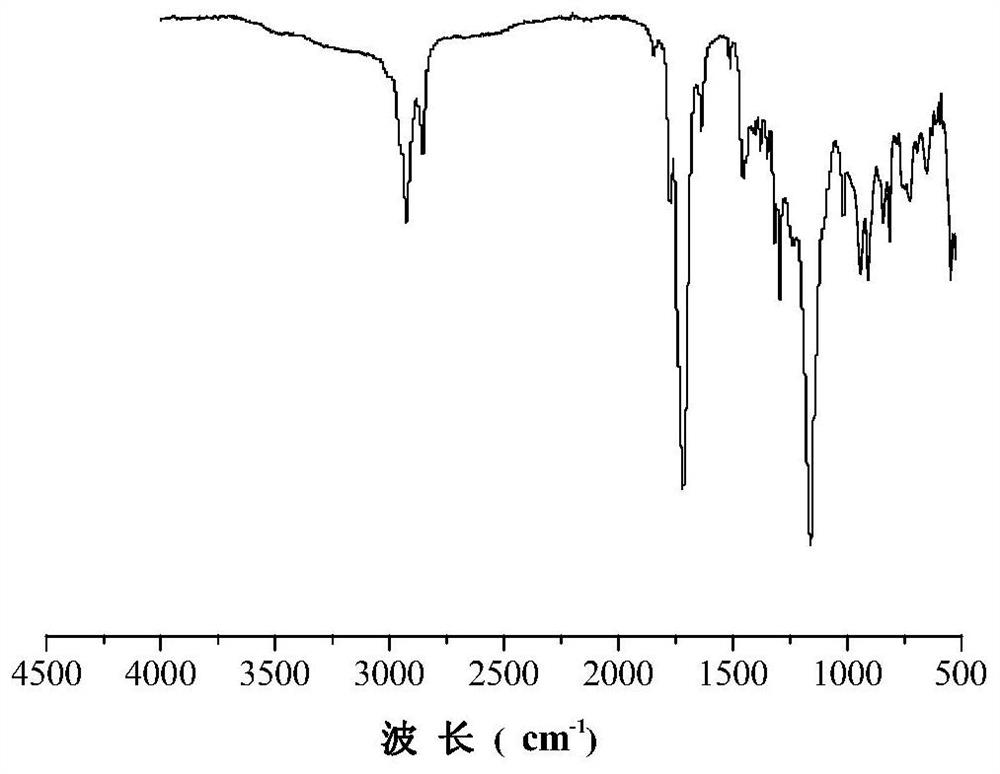

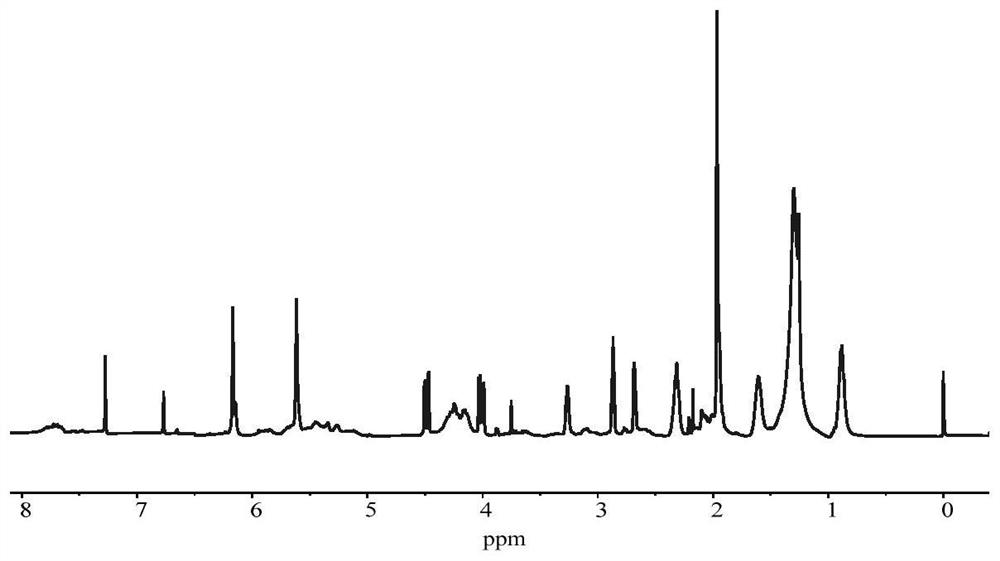

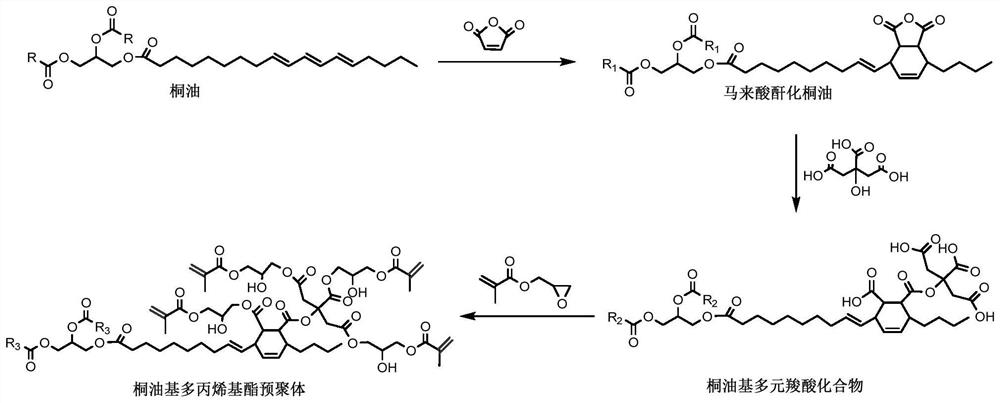

[0019] (1) Add tung oil, maleic anhydride (the molar ratio of maleic anhydride to tung oil is 2:1) and catalyst hydroperoxide (catalyst consumption is 1% of the total weight of the reaction mass) in the reactor, stir evenly and heat React at 200°C for 2 hours to obtain maleic anhydrided vegetable oil;

[0020] (2) Add citric acid (the molar ratio of citric acid to maleic anhydride is 1:1) and catalyst 4-dimethylaminopyridine (catalyst consumption is 3% of the total weight of raw materials) to the above reactor, and heat to 150°C Reaction for 3 hours, followed by purification by water washing and extraction to obtain bio-based polycarboxylic acid compounds;

[0021] (3) Add carboxyglyceryl methacrylate (the molar ratio of carboxyl groups in glycidyl methacrylate to bio-based polycarboxylic acid is 1:1) to the above-mentioned purified bio-based polycarboxylic acid compound, catalyst triphenyl Phosphine (the amount of catalyst is 1% of the total weight of the raw materials) and ...

Embodiment 2

[0024] (1) Add tung oil, maleic anhydride (the molar ratio of maleic anhydride to tung oil is 2:1) and catalyst hydroperoxide (catalyst consumption is 1% of the total weight of the reaction mass) in the reactor, stir evenly and heat React at 200°C for 2 hours to obtain maleic anhydrided vegetable oil;

[0025] (2) Add citric acid (the molar ratio of citric acid to maleic anhydride is 1:1) and catalyst 4-dimethylaminopyridine (catalyst consumption is 3% of the total weight of raw materials) to the above reactor, and heat to 150°C Reaction for 3 hours, followed by purification by water washing and extraction to obtain bio-based polycarboxylic acid compounds;

[0026] (3) Add carboxyglyceryl methacrylate (the molar ratio of carboxyl groups in glycidyl methacrylate to bio-based polycarboxylic acid is 1:1) to the above-mentioned purified bio-based polycarboxylic acid compound, catalyst triphenyl Phosphine (the amount of catalyst is 1% of the total weight of the raw materials) and ...

Embodiment 3

[0029] (1) Add tung oil, maleic anhydride (the molar ratio of maleic anhydride to tung oil is 2:1) and catalyst hydroperoxide (catalyst consumption is 1% of the total weight of the reaction mass) in the reactor, stir evenly and heat React at 200°C for 2 hours to obtain maleic anhydrided vegetable oil;

[0030] (2) Add citric acid (the molar ratio of citric acid to maleic anhydride is 1:1) and catalyst 4-dimethylaminopyridine (catalyst consumption is 3% of the total weight of raw materials) to the above reactor, and heat to 150°C Reaction for 3 hours, followed by purification by water washing and extraction to obtain bio-based polycarboxylic acid compounds;

[0031](3) Add carboxyglyceryl methacrylate (the molar ratio of carboxyl groups in glycidyl methacrylate to bio-based polycarboxylic acid is 1:1) to the above-mentioned purified bio-based polycarboxylic acid compound, catalyst triphenyl Phosphine (the amount of catalyst is 1% of the total weight of the raw materials) and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com