Eugenol methacrylate, preparation method thereof, eugenol-based epoxy vegetable oil acrylate UV curing system and application of eugenol-based epoxy vegetable oil acrylate UV curing system

A clove methacrylate, eugenol-based epoxy technology, applied in the application, sulfide preparation, ink and other directions, can solve the problems of high production conditions, limited use of epoxy acrylates, poor biodegradability, etc. Improve anti-corrosion performance and tensile strength, reduce the time of light curing, and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of eugenol methacrylate of the present implementation, comprises the steps:

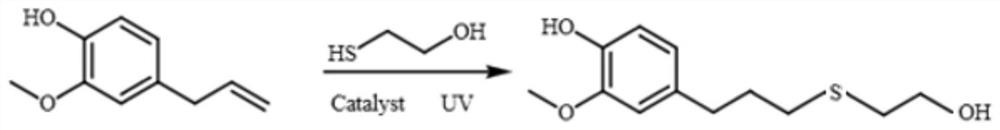

[0044] (1) Add 16.42g eugenol (purity 99%), 8.59g 2-mercaptoethanol and 0.73g photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone (eugenol) into a quartz test tube The molar ratio with 2-mercaptoethanol is 1:1.1, and the amount of photoinitiator is 3% of the sum of the mass of eugenol and 2-mercaptoethanol), react for 6h under the irradiation of 365nm ultraviolet light, wash the reaction product three times, Then, it was dried with anhydrous magnesium sulfate to obtain eugenol polyol. The reaction scheme of this step is as follows figure 1 shown.

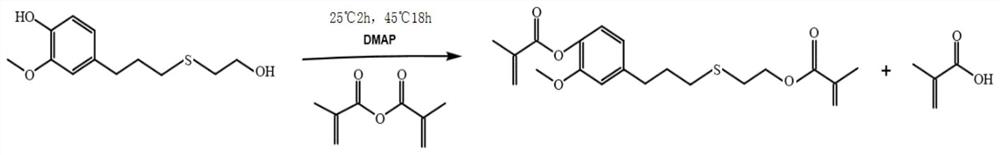

[0045](2) 10g of eugenol polyol obtained in step (1), 0.25g of 4-dimethylaminopyridine were added to the flask with a thermometer, then 15.90g of methacrylic anhydride was slowly added with a dropping funnel under an ice-water bath (The molar ratio of eugenol polyol and methacrylic anhydride is 1:2.5, and the amount of 4...

Embodiment 2

[0049] The preparation method of the epoxidized soybean oil acrylate of the present embodiment comprises the following steps:

[0050] In a three-necked flask with a thermometer, add 20.00g epoxidized soybean oil (ESO), 4.56g acrylic acid (AA) (purity 99%), 0.25g triphenylphosphine and 0.06g hydroquinone (epoxidized soybean oil and The molar ratio of acrylic acid is 1:3, the amount of triphenylphosphine is 1 wt % of the sum of the mass of epoxidized soybean oil and acrylic acid, and the amount of hydroquinone is 1 wt % of the mass of acrylic acid), mechanically stirred at 80 ° C for 0.5 wt % h, then the temperature was raised to 120 °C and the reaction was continued for 2 h to obtain epoxidized soybean oil acrylate (AESO). The reaction scheme of this step is as follows Figure 4 shown.

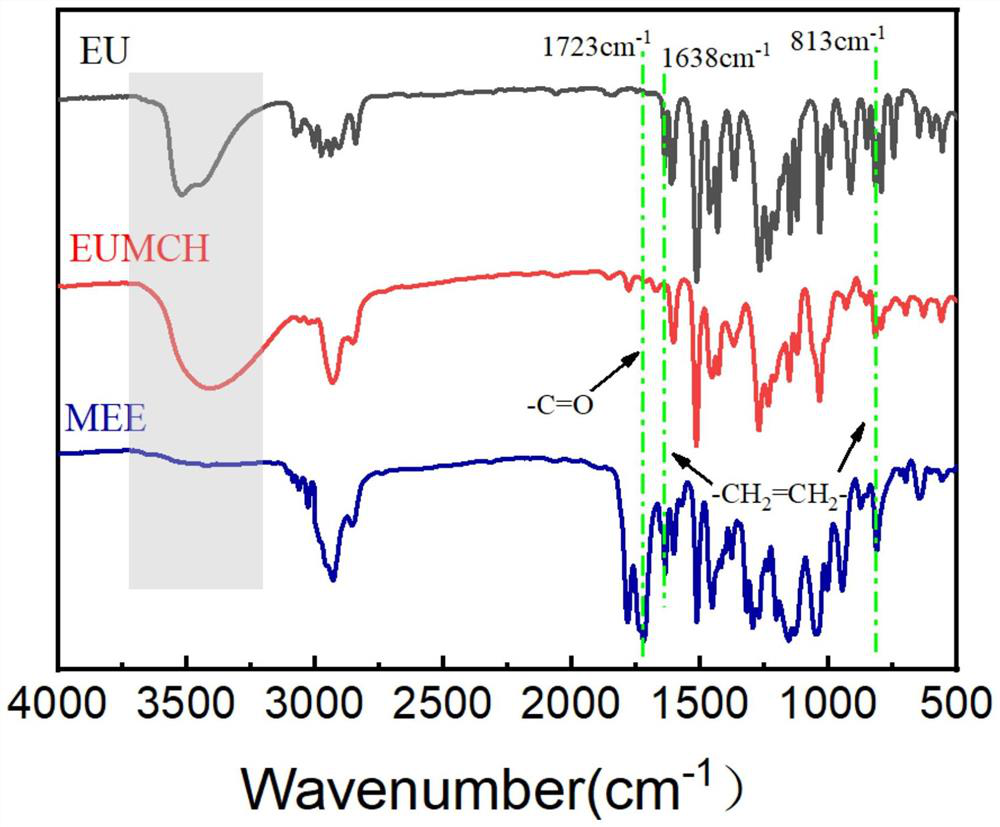

[0051] The Fourier transform infrared spectrogram of the epoxidized soybean oil of the present embodiment and the epoxidized soybean oil acrylate is as follows Figure 5 shown. from Figu...

Embodiment 3

[0054] The epoxidized soybean oil acrylate UV curing system of this embodiment includes the epoxidized soybean oil acrylate prepared according to the preparation method of Example 2 and the photoinitiator 2-hydroxy-2-methyl-1-phenyl-1- acetone. When preparing the photocurable film, 10 g of epoxidized soybean oil acrylate was used as a prepolymer, and then 0.3 g of photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com