Environmental-friendly foamed insole material, and preparation method thereof

An environmentally friendly and brewing technology, applied in shoe soles, applications, clothing, etc., can solve the problems of white pollution, high degree of polymerization, and difficulty in breaking and decomposing polymer chains, and achieve the effect of reducing emissions and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Embodiments of the present invention provide a method for preparing an environmentally friendly foam midsole material as described above, comprising the following steps:

[0051] The EVA composite material is sequentially mixed and granulated, and then foamed to obtain an environmentally friendly foam midsole material.

[0052] The process flow of the embodiment of the present invention mainly includes: weighing→mixing→granulation→foaming→baking. In the embodiment of the present invention, first group and weigh: according to the dosage of the formula, the main plastic materials such as EVA / POE / EPDM / PLA / PBAT are weighed as the first group, and the plant fiber powder is weighed as the second group, stearic acid, Zinc stearate and zinc oxide are named for the third group; DCP and blowing agent are named for the fourth group.

[0053] In the embodiment of the present invention, the weighed components are mixed: first, pour the first group of materials into the internal mix...

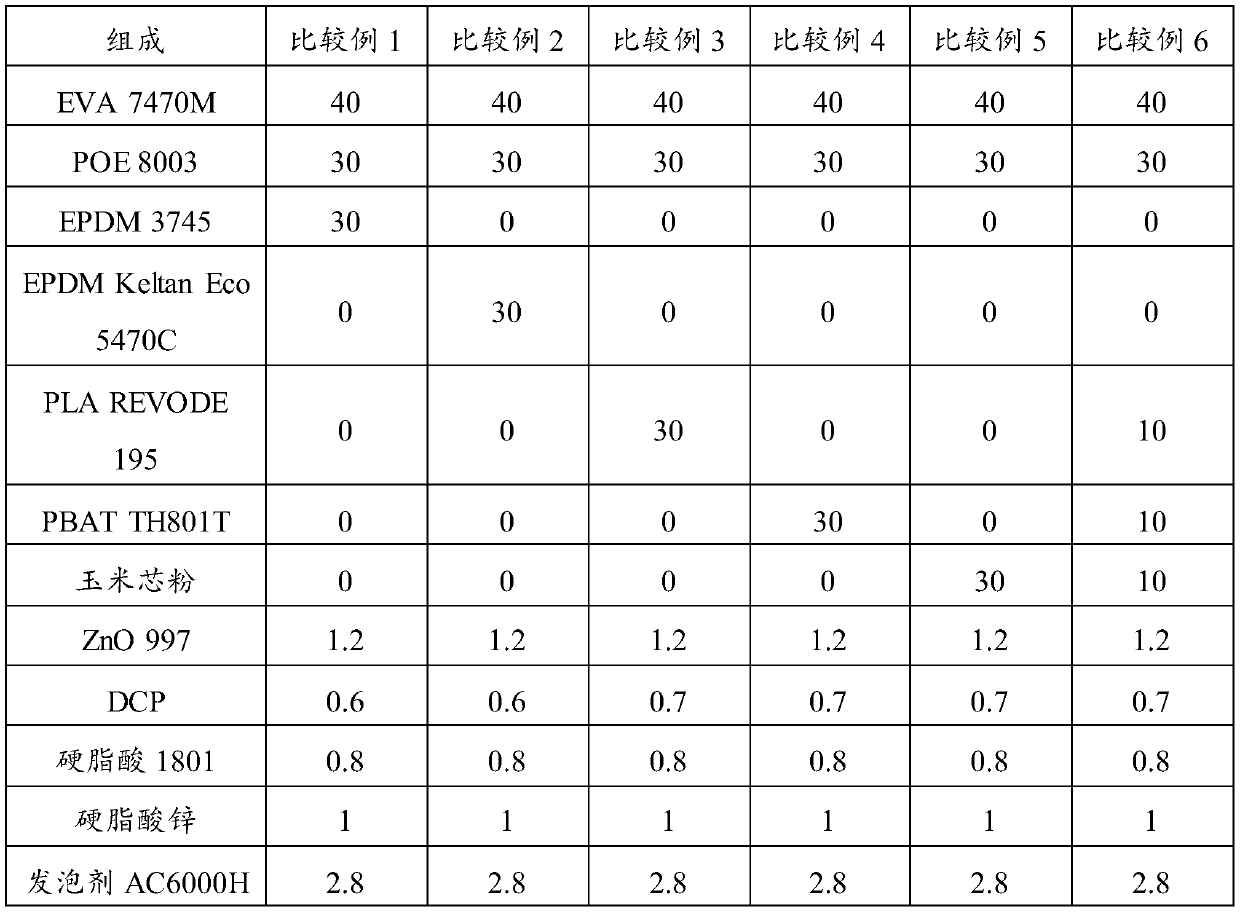

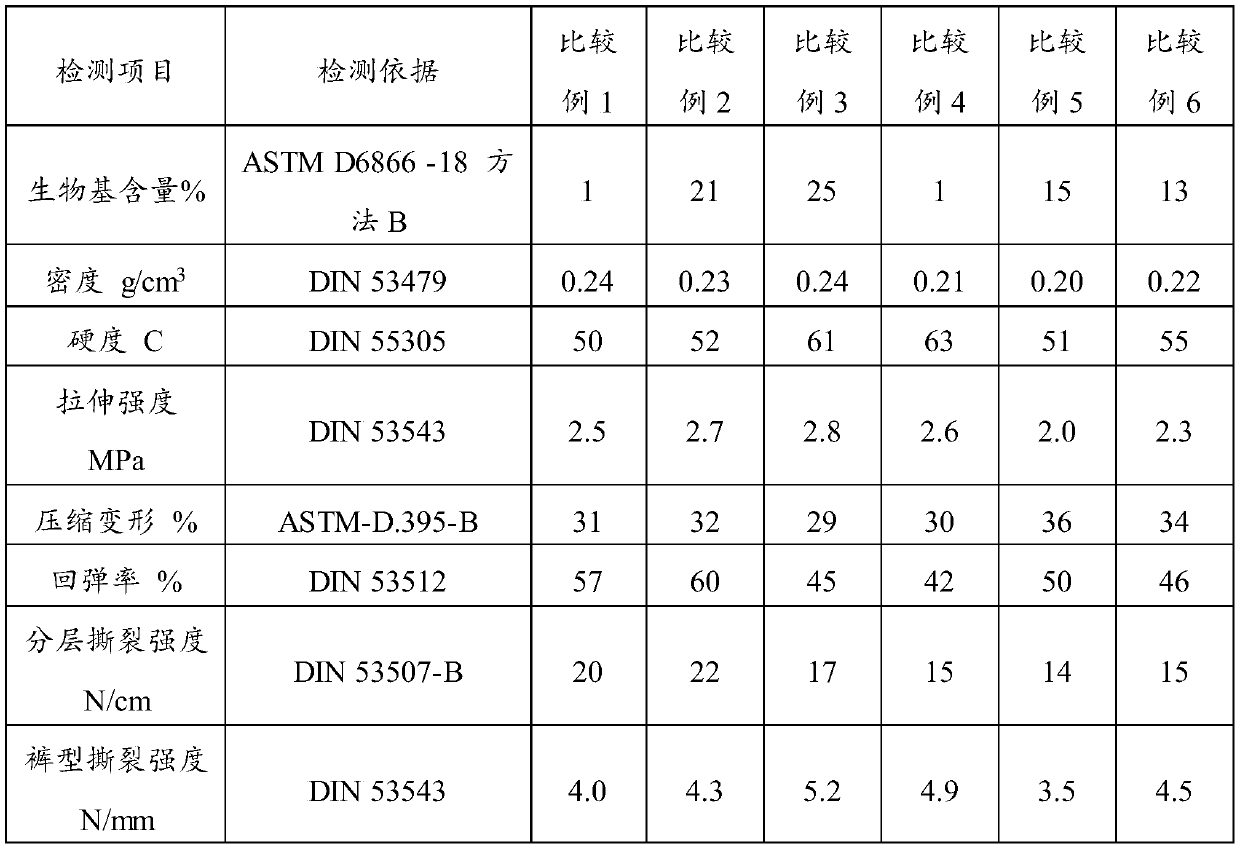

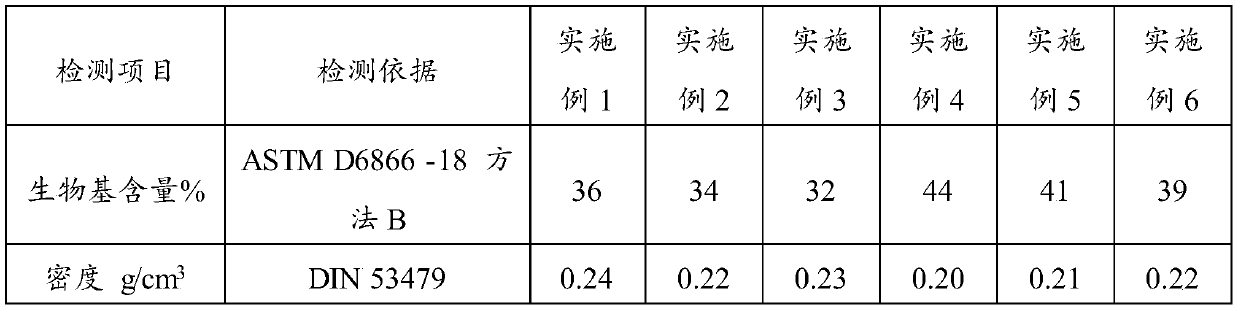

Embodiment 1

[0060] Weighing: According to the dosage of the formula in Table 1, the main plastic materials such as EVA / POE / EPDM / PLA / PBAT are weighed as the first group, and the plant fiber powder is weighed as the second group. Stearic acid, zinc stearate , Zinc oxide is called the third group; DCP and foaming agent are called the fourth group.

[0061] Mixing: first pour the first group of materials into the internal mixer, and start the machine, when the temperature rises to 80-85 ° C, then pour the second group of materials; when the temperature rises to 90-95 ° C, pour The third group of materials; when the temperature rises to 100-110°C, pour in the fourth group of materials, and after mixing for 5 minutes, pour out the mixed materials.

[0062] Material making: Pour the mixed material into the material making machine, and adjust the temperature of the first, second, third, and fourth zones to 75, 80, 85, and 90°C respectively. And, the screw speed is adjusted to 40-50 rpm, and the ...

Embodiment 2-6

[0066] According to the steps of Example 1, the formulations are shown in Table 1, and environmentally friendly foam midsole materials were prepared respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com