3D printing inorganic salt reinforced palm oil-based high-performance elastomer

A 3D printing, palm oil technology, applied in additive processing, fatty acid production, fatty acid chemical modification, etc., can solve the problems of difficult photo-curing printing of thermoplastic materials, poor mechanical properties of vegetable oil elastomers, and complex preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

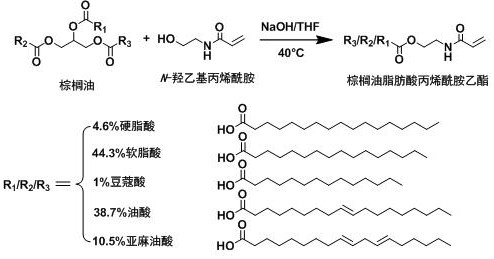

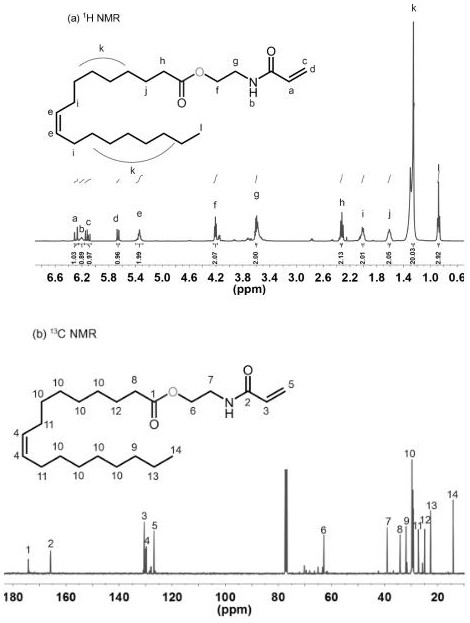

Method used

Image

Examples

Embodiment 1

[0031] 3D printing inorganic salt reinforced palm oil-based high-performance elastomer:

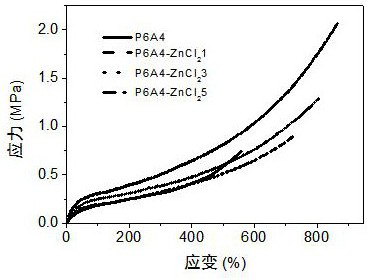

[0032] Elastomer preparation method: 12g palm oil propylene-based monomer, 8g acrylic acid, 0.2g ZnCl 2 and 0.4g of photoinitiator were poured into a round-bottomed flask and magnetically stirred in a water bath at 60°C for 1h, and then the mixed solution was poured into a digital light processing 3D printer. h for printing.

[0033] In the preparation process, the amount ratio of palm oil propylene-based monomer to acrylic acid is 6:4 by mass ratio; the inorganic salt reinforcement ZnCl 2 1% of the mass of the elastomer, and the amount of the initiator is 2% of the mass of the elastomer.

Embodiment 2

[0035] 3D printing inorganic salt reinforced palm oil-based high-performance elastomer:

[0036] Elastomer preparation method: 12g palm oil propylene monomer, 8g acrylic acid, 0.6g ZnCl 2 and 0.4g of photoinitiator were poured into a round-bottomed flask in a water bath at 60 °C for 1 h, and then the mixed solution was poured into a digital light processing 3D printer. h for printing.

[0037] In the preparation process, the amount ratio of palm oil propylene-based monomer to acrylic acid is 6:4 by mass ratio; the inorganic salt reinforcement ZnCl 2 3% of the mass of the elastomer, and the amount of the initiator is 2% of the mass of the elastomer.

Embodiment 3

[0039] 3D printing inorganic salt reinforced palm oil-based high-performance elastomer:

[0040] Elastomer preparation method: 12g palm oil propylene monomer, 8g acrylic acid, 1gZnCl 2 and 0.4g of photoinitiator were poured into a round-bottomed flask in a water bath at 60 °C for 1 h, and then the mixed solution was poured into a digital light processing 3D printer. h for printing.

[0041] In the preparation process, the amount ratio of palm oil propylene-based monomer to acrylic acid is 6:4 by mass ratio; the inorganic salt reinforcement ZnCl 2 5% of the mass of the elastomer, and the amount of the initiator is 2% of the mass of the elastomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile stress | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com