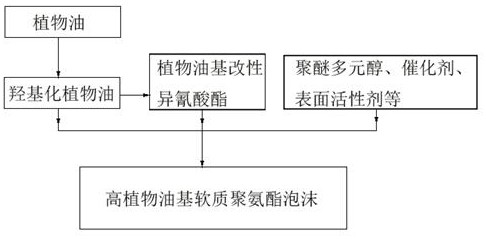

Synthesis process and application of vegetable oil-based modified isocyanate

A vegetable oil-based and isocyanate technology, which is applied in the field of vegetable oil-based modified isocyanate, can solve the problems of out-of-shape products, the inability to further increase the content of bio-based materials, and the difficulty of degrading flexible polyurethane foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The first step is the preparation of hydroxylated vegetable oil:

[0031] Modification of epoxy vegetable oil into hydroxylated vegetable oil, hydroxyl value 50-120mgKOH / g, refer to CN101186694 (CN101186694B);

[0032] The second step is the vegetable oil modified isocyanate:

[0033] Reaction of isocyanate and hydroxylated vegetable oil, modified TDI isocyanate content 30-42%, modified MDI isocyanate content 15-25%, modified TDI / MD mixed isocyanate content 18-35% %.

[0034] Isocyanates include: TDI, MDI, or a mixture of TDI and MDI.

[0035] The third step is the technology of flexible polyurethane foam:

[0036] Use hydroxylated vegetable oil, petroleum-based polyether polyol and petroleum-based polymer polyol, add catalyst, silicone oil surfactant, foaming agent, and react with vegetable oil-based isocyanate to obtain a high-vegetable oil-based soft gel containing 30%-50%. quality polyurethane foam.

[0037] Specific production steps:

[0038] 1. Preparation o...

Embodiment 1

[0047]Use a 500ml three-necked flask with a dropping funnel, add TDI: 350g into the three-necked flask, add 100g of hydroxylated vegetable oil A to the dropping funnel, heat the three-necked flask to 90-95°C, turn on the switch of the dropping funnel, and slowly add hydroxyl Add vegetable oil A in one hour, keep the temperature at 85-95°C, after adding, raise the temperature to 95-100°C, keep it warm for 2-4 hours, cool down to 40-60°C and discharge. The vegetable oil-based modified isocyanate JS-01 was obtained, the tested isocyanate content: 36.4%, viscosity (cps): 471 / 25°C, and vegetable oil-based content 21.1%.

Embodiment 2

[0049] Use a 500ml three-necked flask with a dropping funnel, add TDI: 200g into the three-necked flask, add 100g of hydroxylated vegetable oil A to the dropping funnel, heat the three-necked flask to 90-95°C, turn on the switch of the dropping funnel, and slowly add hydroxyl Vegetable oil A is added in one hour, and the temperature is maintained at 85-95°C. After the addition, the temperature is raised to 95-100°C, kept for 2-4 hours, cooled to 40-60°C and discharged to obtain vegetable oil-based modified isocyanate JS- 02. Tested isocyanate content: 30.4%, viscosity (cps): 556 / 25 degrees, vegetable oil base content 31.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com