Multifunctional membrane coating liquid suitable for ink-jet and laser printing, and preparation method thereof

A laser printing and multi-functional technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of single function and inability to be widely used in different products, and achieve the effect of smooth surface, good antistatic effect and avoiding paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

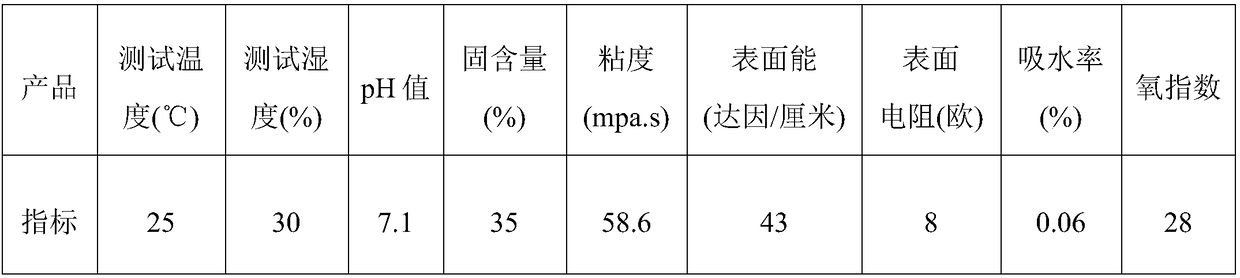

Embodiment 1

[0060] Add 15g of polycarbonate diol into a 500ml four-necked flask, raise the temperature to 85°C, then vacuum-dry for 1 hour, cool down to 55°C, add 40g of isophorone diisocyanate, and then gradually raise the temperature to 80°C. After reacting for 1.5 hours, lower the temperature to 45°C, add 0.015g of bismuth-zinc composite catalyst, 8.20g of hydrophilic chain extender dimethylol butyric acid, 5.10g of crosslinking agent 1,4-butanediol, trimethylolpropane 2.75g, 4.05g of 4-hydroxybutyl acrylate, gradually raise the temperature to 63°C, then add 10.52g of acetone, and continue the reaction for 4 hours. Cool down to 20°C, add 3.21g of triethylamine for neutralization, and continue the reaction for 15 minutes. 68.16g of ionized water, after stirring for 15min, slowly add 1.10g of chain extender ethylenediamine for secondary chain extension and last for 15min, the rate of dropping ethylenediamine is controlled between 0.10g / min, and the modified waterborne polyurethane is obt...

Embodiment 2

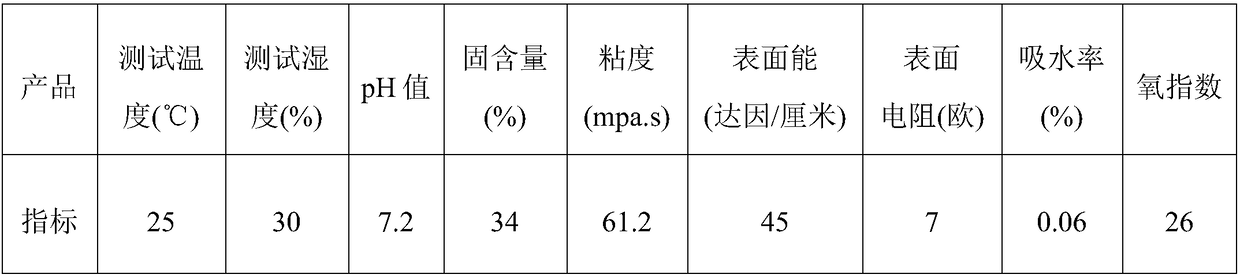

[0073] Add 12g of polycarbonate diol into a 500ml four-necked flask, raise the temperature to 85°C, then vacuum-dry for 1.5 hours, cool down to 60°C, add 40g of isophorone diisocyanate, and then gradually raise the temperature to 85°C. After reacting for 2 hours, lower the temperature to 55°C, add 0.016g of bismuth-zinc composite catalyst, 7.80g of hydrophilic chain extender dimethylol butyric acid, 5.20g of crosslinking agent 1,4-butanediol, trimethylolpropane 2.60g, 4.68g of 4-hydroxybutyl acrylate, gradually raise the temperature to 65°C, then add 11.20g of acetone, and continue the reaction for 5 hours. Cool down to 20°C, add 3.01g of triethylamine for neutralization, and continue the reaction for 15 minutes. 71.20g of ionized water, after stirring for 15min, slowly add 1.08g of chain extender ethylenediamine for secondary chain extension and last for 15min, the rate of dropping diamine is controlled between 0.15g / min, and the modified waterborne polyurethane is obtained ...

Embodiment 3

[0086] Add 16g of polycarbonate diol into a 500ml four-necked flask, raise the temperature to 83°C, then vacuum-dry for 1.5 hours, cool down to 58°C, add 40g of isophorone diisocyanate, and then gradually raise the temperature to 85°C. After reacting for 2 hours, lower the temperature to 55°C, add 0.020g of bismuth-zinc composite catalyst, 5.60g of hydrophilic chain extender dimethylol butyric acid, 4.48g of crosslinking agent 1,4-butanediol, trimethylolpropane 1.68g, 3.92g of 4-hydroxybutyl acrylate, the temperature was gradually raised to 65°C, and then 10.80g of acetone was added, and the reaction was continued for 5 hours. Cool down to 20°C, add 2.90g of triethylamine for neutralization, and continue the reaction for 15 minutes. 75.10g of ionized water, after stirring for 15min, slowly add 1.12g of chain extender ethylenediamine for secondary chain extension and last for 15min, the rate of dropping diamine is controlled between 0.09g / min, and the modified waterborne polyur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com