Internal insulation spool and manufacturing method thereof

A production method and internal insulation technology, applied in the direction of insulators, insulators, coatings, etc., can solve problems such as poor dispersion of titanium dioxide, and achieve the effects of enhanced wear resistance, wide application, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An inner insulating wire tube, comprising a metal tube, the inner wall of the metal tube is provided with an insulating layer, and the insulating layer includes the following components in parts by weight:

[0032] 25 parts of nano-silica, 25 parts of polycarbonate resin, 0.2 part of polyvinyl chloride, 1.6 parts of carbon fiber, 5 parts of alkyd resin, 1 part of silane coupling agent, 0.1 part of zinc oxide, 4 parts of bamboo leaf residue.

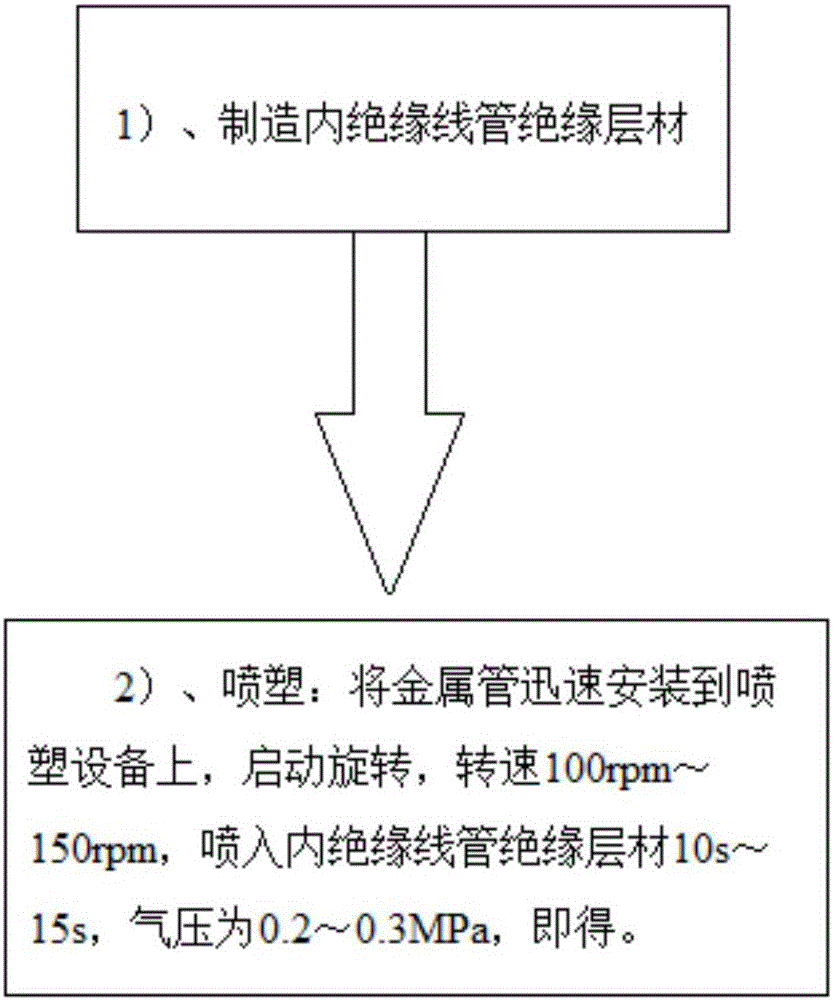

[0033] figure 1 As shown, the manufacturing method of the inner insulating wire tube includes the following steps:

[0034] 1) Fully mix polycarbonate resin, alkyd resin, nano-silica, and bamboo leaf residue in an ultrasonic generator for 3-5 minutes, and pass through a 200-250-mesh sieve;

[0035] 2) Add carbon fiber to deionized water, stir evenly at 40-50°C at a speed of 900-1500r / min;

[0036] 3) Add polyvinyl chloride, coupling agent and zinc oxide in sequence, and heat up to 60°C for 1.5-2 hours;

[0037] 4) Use a Buchner ...

Embodiment 2

[0044] An inner insulating wire tube, comprising a metal tube, the inner wall of the metal tube is provided with an insulating layer, and the insulating layer includes the following components in parts by weight:

[0045] 40 parts of nano-silica, nano-silica is calcite-type cube-shaped nanoparticles, and its particle size

[0046] ≤50nm,

[0047] 15 parts of polycarbonate resin, 0.6 part of polyvinyl chloride, 0.8 part of carbon fiber, 2 parts of alkyd resin, 3 parts of borate coupling agent, 0.5 part of zinc oxide, 8 parts of bamboo leaf residue.

[0048] The manufacturing method of the inner insulating wire tube includes the following steps:

[0049] 1) Fully mix polycarbonate resin, alkyd resin, nano-silica, and bamboo leaf residue in an ultrasonic generator for 3-5 minutes, and pass through a 200-250 mesh sieve; the power of the ultrasonic generator is 1.2KW, and the time 15 minutes, the working method is intermittent work, every 30 seconds of work, 30 seconds of pause; ...

Embodiment 3

[0059]An inner insulating wire tube, comprising a metal tube, the inner wall of the metal tube is provided with an insulating layer, and the insulating layer includes the following components in parts by weight:

[0060] 30 parts of nano-silica, nano-silica is calcite-type cubic nanoparticles, and its particle size is ≤ 50nm;

[0061] 22 parts of polycarbonate resin, 0.4 parts of polyvinyl chloride, 1.2 parts of carbon fiber, 3.5 parts of alkyd resin,

[0062] 2 parts of silane coupling agent, titanate coupling agent and aluminate coupling agent with a mass ratio of 2:3 to 5:1, 0.3 parts of zinc oxide, and 6 parts of bamboo leaf residue.

[0063] The manufacturing method of the inner insulating wire tube includes the following steps:

[0064] 1) Fully mix polycarbonate resin, alkyd resin, nano-silica, and bamboo leaf residue in an ultrasonic generator for 3-5 minutes, and pass through a 200-250-mesh sieve; the power of the ultrasonic generator is 1.5KW, and the time 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com