Full-biodegradable balloon bottom support and preparation method thereof

An all-biological and balloon technology, applied in the field of balloon support, can solve problems such as white pollution, and achieve the effects of low equipment requirements, strong product market competitiveness, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Correspondingly, the embodiment of the present invention provides a method for preparing a fully biodegradable balloon base as described above, including the following steps:

[0037] According to parts by mass, blend polylactic acid, toughening agent, filler, lubricant and compatibilizer to obtain a material;

[0038] The material is passed through extrusion and injection molding processes to obtain a fully biodegradable balloon base.

[0039] In the embodiment of the present invention, raw material components such as polylactic acid, toughening agent, filler, etc. are put into a blender in proportion to mix to obtain materials; the content of each component's dosage ratio, type selection, etc. are as described above.

[0040] In the embodiment of the present invention, the obtained material is put into a twin-screw extruder for melt extrusion, granulated to obtain a special material, and the temperature of extrusion melting may be 160-200°C.

[0041] In the embodiment of the pr...

Embodiment 1

[0049] According to the mass ratio of 80 parts of PLA, 18 parts of PBAT, 1 part of EBS, 0.5 part of KH550, 0.5 part of talc (particle size greater than 100 mesh), the raw material components are put into the mixer for blending to obtain the material; Said material is put into the twin-screw extruder to enter into the melt extrusion, granulated to obtain the special material, the extrusion melting temperature is 160-200℃;

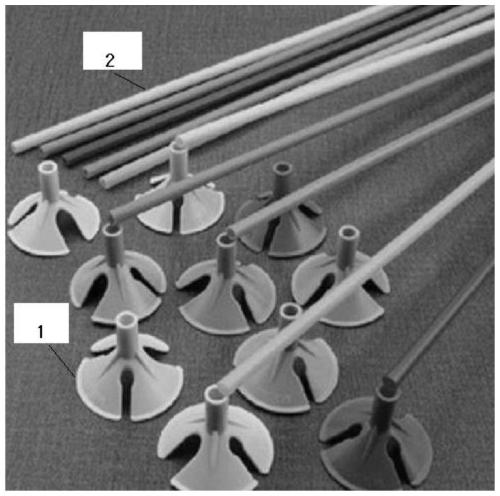

[0050] Then, put the special material into the injection molding machine for melt injection molding, the injection temperature is 160-200℃, and the finished balloon bottom support is prepared, the structure is as figure 1 Midsole support 1.

[0051] In addition, the special material is made into a standard sample, and the performance test is performed. The result is: the tensile strength is 35 MPa, and the elongation at break is 168%.

Embodiment 2

[0053] According to the mass ratio of 75 parts of PLA, 10 parts of PCL, 12.5 parts of calcium carbonate (particle size greater than 100 mesh), 2 parts of EBS, and 0.5 parts of KH550, the raw material components are put into the mixer for blending to obtain materials; Said material is put into the twin-screw extruder to enter into the melt extrusion, granulated to obtain the special material, the extrusion melting temperature is 160-200℃;

[0054] Then, put the special material into the injection molding machine for melt injection molding, and the injection temperature is 160-200°C to prepare the finished balloon bottom support. The structure is as figure 1 Midsole support 1.

[0055] In addition, the special material was made into a standard sample, and the performance test was performed. The result was that the tensile strength was 29 MPa and the elongation at break was 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com