Device and method for continuously synthesizing poly (propylene carbonate) polyols

A polypropylene carbonate and polyol technology, applied in the chemical industry, can solve the problems of low gas-liquid two-phase mass transfer rate, non-continuous production, and low product quality, so as to improve CO2 utilization rate, reduce raw material consumption, and improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

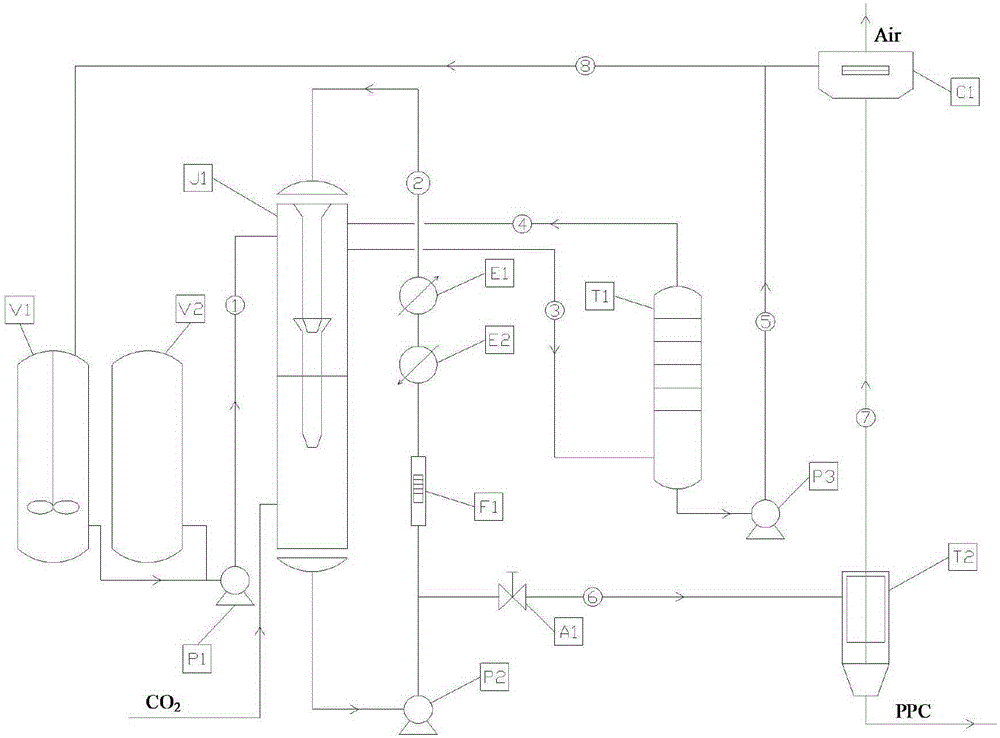

[0043] The present embodiment provides a kind of device of continuous synthesis polypropylene carbonate polyol, such as figure 1 As shown, the device comprises a dual-stage jet reactor J1 and a scraped thin film evaporator T2;

[0044] Wherein, the upper part of the two-stage jet reactor J1 is provided with liquid-phase material inlets respectively connected to the propylene oxide and catalyst storage tank V1 and the molecular weight regulator storage tank V2, and the bottom is provided with a gas-phase raw material inlet;

[0045] The two-stage jet reactor J1 is also provided with an exhaust port on the upper part and a liquid phase product output port on the bottom. The exhaust port is connected to the gas-liquid separator T1 through a gas delivery pipeline, and the liquid phase product output port is connected through a pipeline. To the feed port of the scraped film evaporator T2; the bottom of the scraped film evaporator T2 is connected to the polypropylene carbonate polyo...

Embodiment 2

[0050] This embodiment provides a method for continuously synthesizing polypropylene carbonate polyols using the device described in Example 1. The synthesis process of polypropylene carbonate polyols is as follows figure 1 Shown:

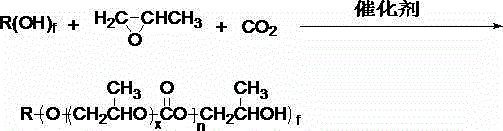

[0051] (1) Mix propylene oxide (PO) with catalyst, store in propylene oxide and catalyst storage tank V1, and keep stirring; add molecular weight regulator R(OH) f Stored in Molecular Weight Regulator Storage Tank V2. After starting up, the two storage tanks output raw materials at a certain ratio, and are sent to the dual-stage jet reactor J1 from the top by the delivery pump P1 through the pipeline 1. CO 2 The gas is passed into the dual-stage jet reactor J1 from the bottom.

[0052] (2) After a certain amount of raw materials are accumulated in the dual-stage jet reactor J1, the circulation pump P2 is turned on, and the mixed material is sent to the dual-stage jet reactor J1 from the top through the pipeline 2 to form a circulation. At this ...

Embodiment 3

[0057] This embodiment provides a method for continuously synthesizing polypropylene carbonate polyols using the device described in Embodiment 1. Compared with Embodiment 2, the only difference is: in this embodiment, the dual-stage jet reactor is high 16m, inner diameter 0.8m. Molecular weight regulator is glycerol, the mass dosage ratio of propylene oxide and catalyst is 1000:1; The molar dosage ratio of propylene oxide and molecular weight regulator is 8:1; CO 2 The molar dosage is 1 / 4 of that of propylene oxide, the reaction temperature is 60°C, the residence time is 4h, and the yield is 91%. Compared with loop reactors of the same scale, the reaction energy consumption is reduced by 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com