Patents

Literature

64results about How to "Reduce the use of manpower and material resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

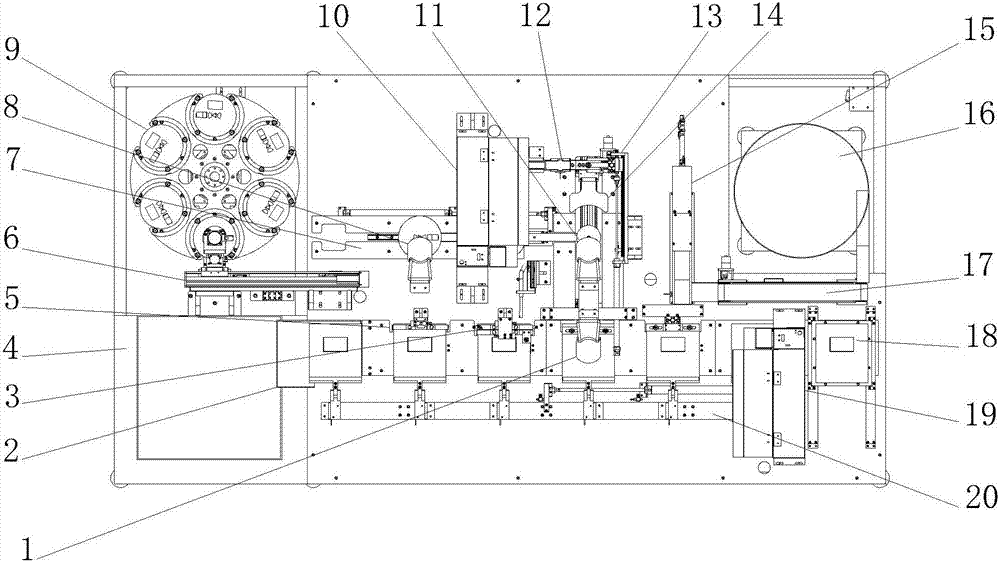

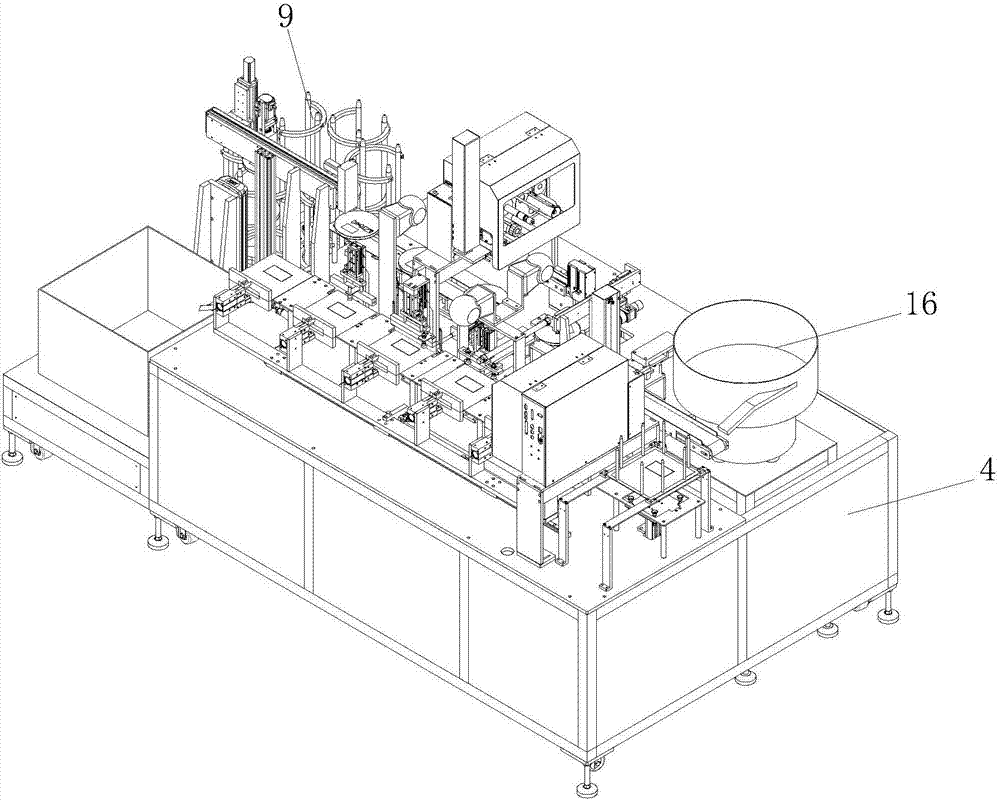

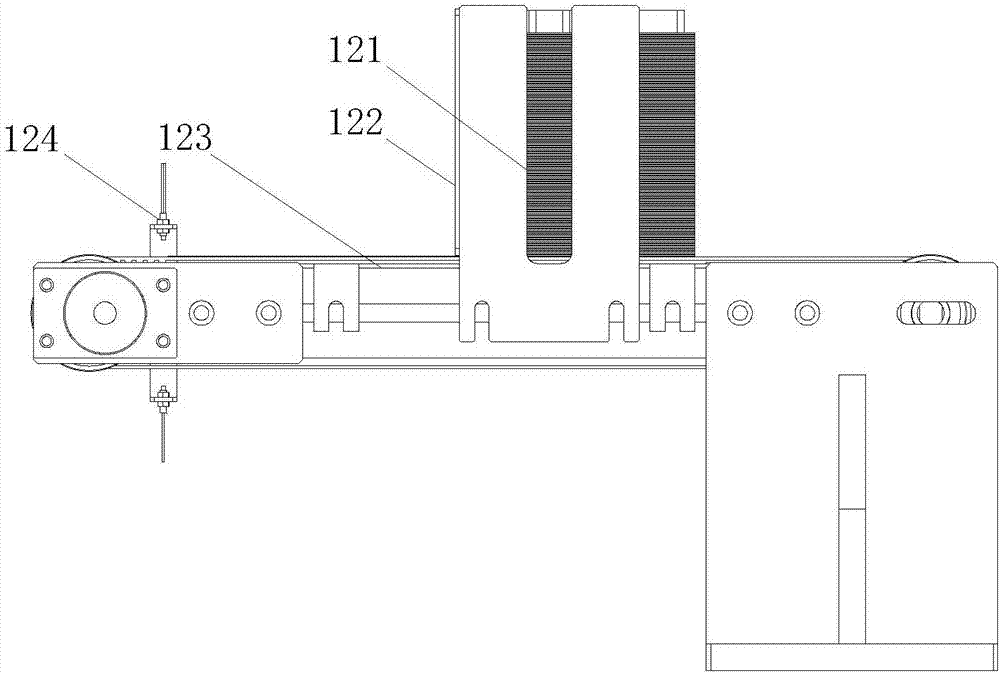

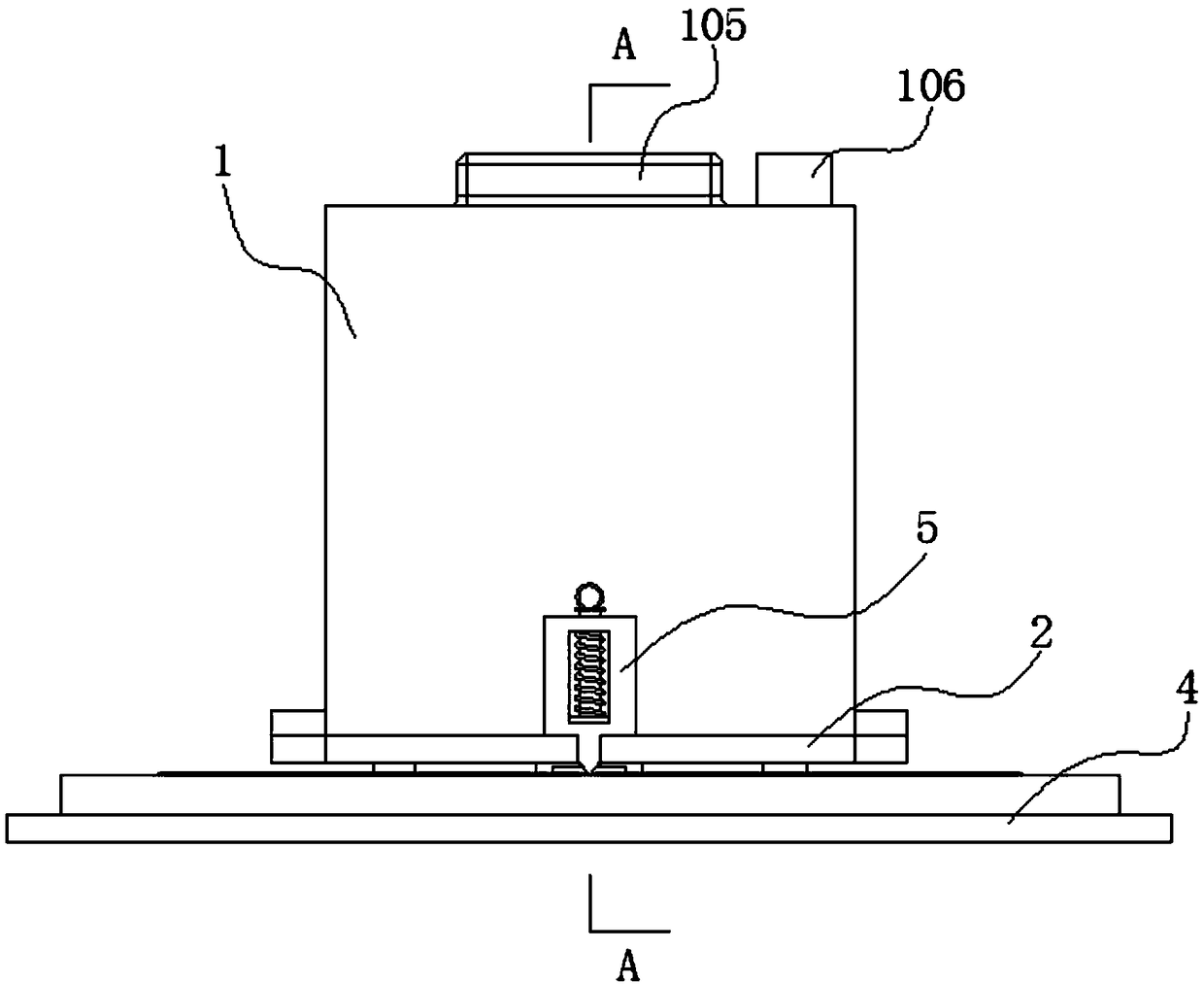

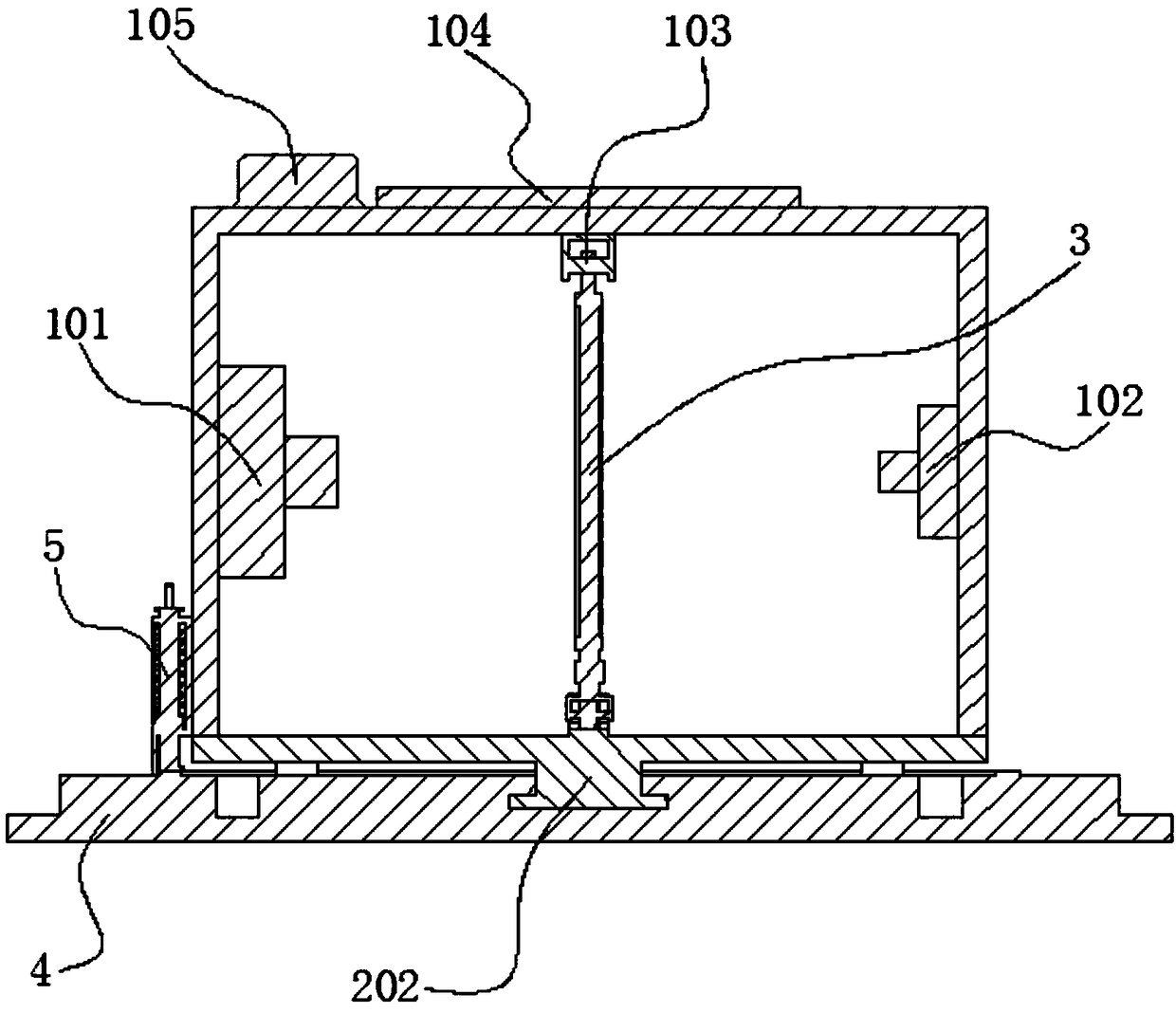

Intelligent packaging machine

PendingCN107985669AReduce volumeEasy to adjustPackaging by pressurising/gasifyingWrapper twisting/gatheringHuman–machine interfaceMan machine

The invention discloses an intelligent packaging machine. The intelligent packaging machine comprises a worktable, an electronic warehouse is fixedly arranged on one side of the top of the worktable,a vacuum sealing mechanism is arranged on one side of a cooling embossing mechanism, and a lower heating block is arranged at the bottom of a first glue bag. According to the intelligent packaging machine, an electronic material disc transplanting mechanism jacks up and puts down a disc through rising and falling actions of a lifting air cylinder, after the lifting air cylinder rises, the electronic material disc is jacked up, the electronic material disc transplanting air cylinder moves the electronic material disc, the material disc can reach the next station, the lifting air cylinder descends, the electronic material disc is put down and returns to the original position, and overloading is achieved; according to customer product characteristics, a function unit assembly is achieved, one-step operation from raw materials to products is achieved, use of manpower and material resources is reduced, unit cooperation is optimized, the automation degree is high, workshop space occupying issmall, the pollution source is small, power consumption is little, the cost is low, maintaining is easy, and unit matching can be finished through man-machine interface communication operation by oneperson.

Owner:广东金昇智能数控有限公司

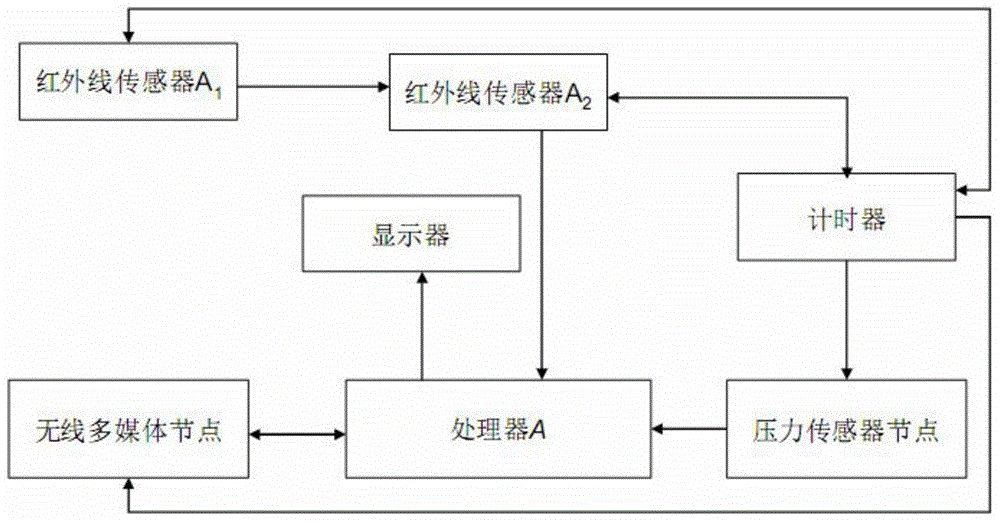

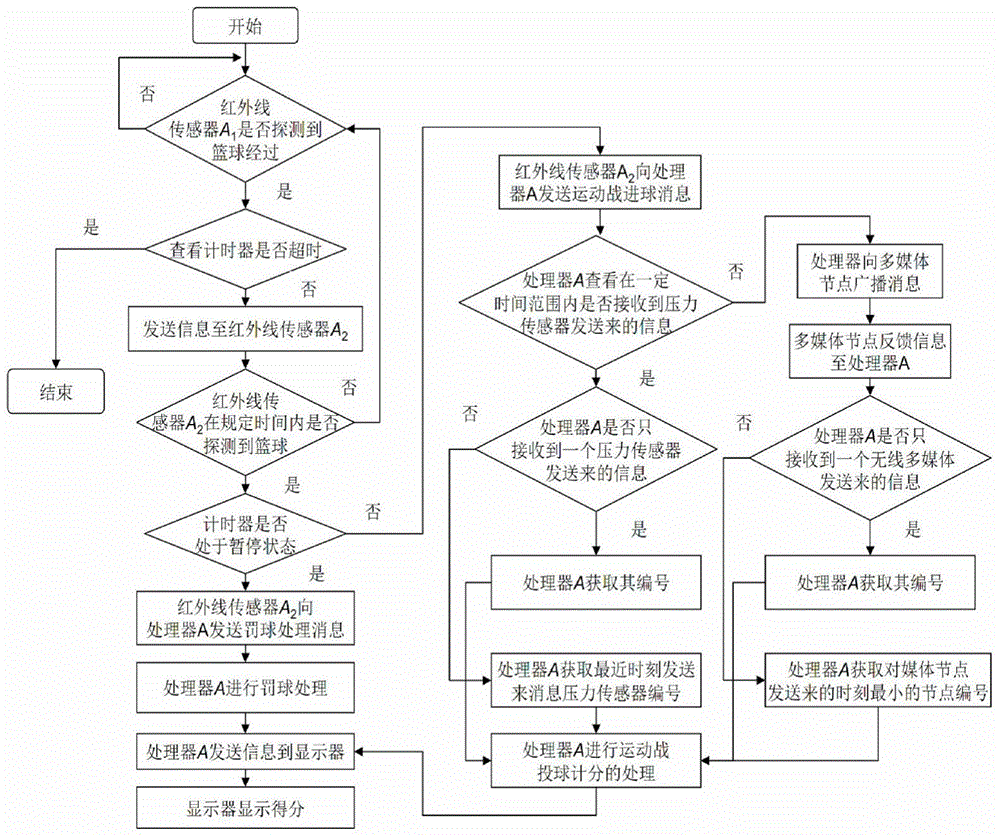

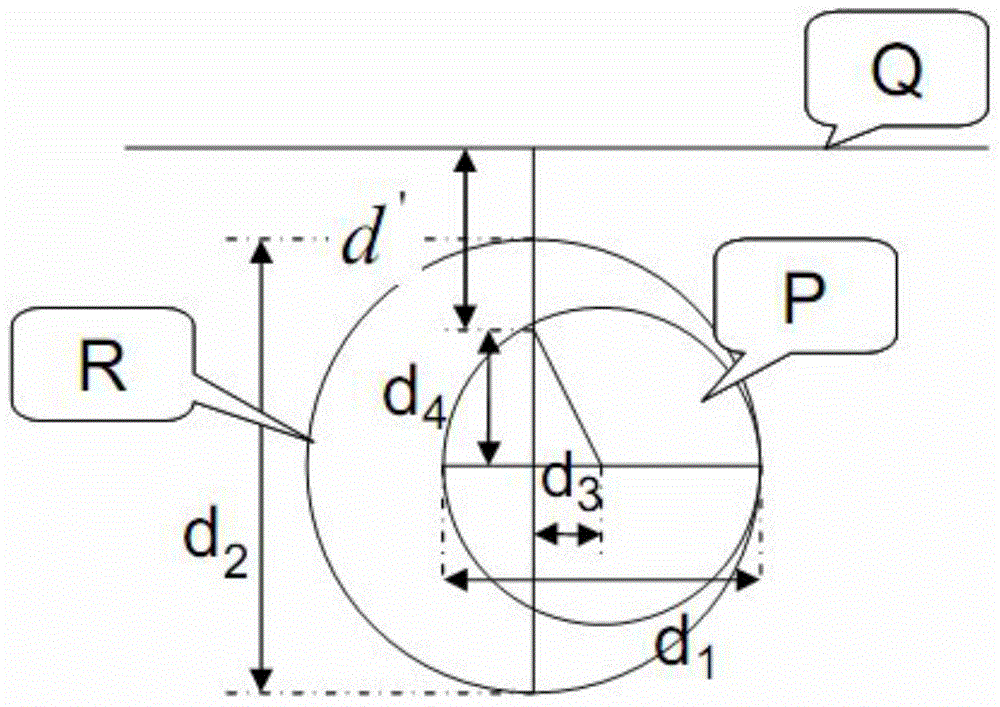

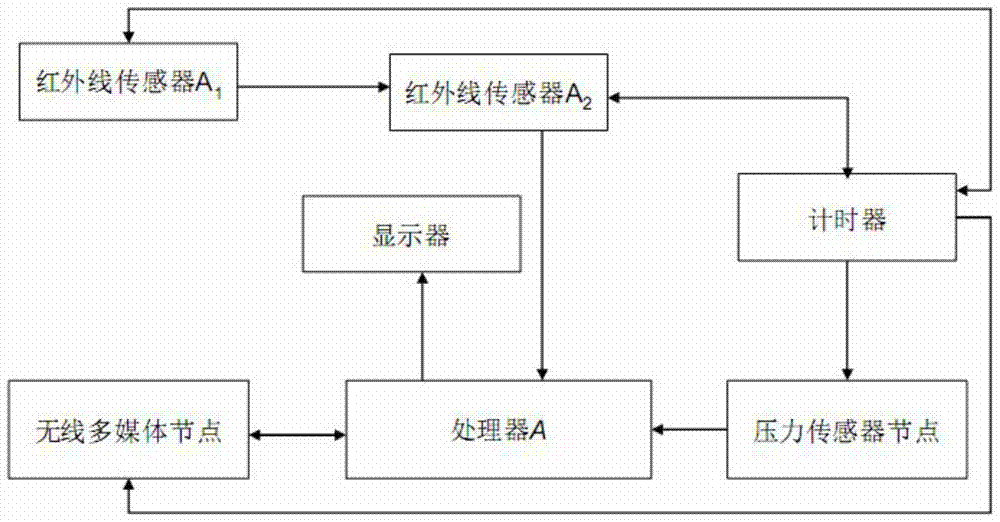

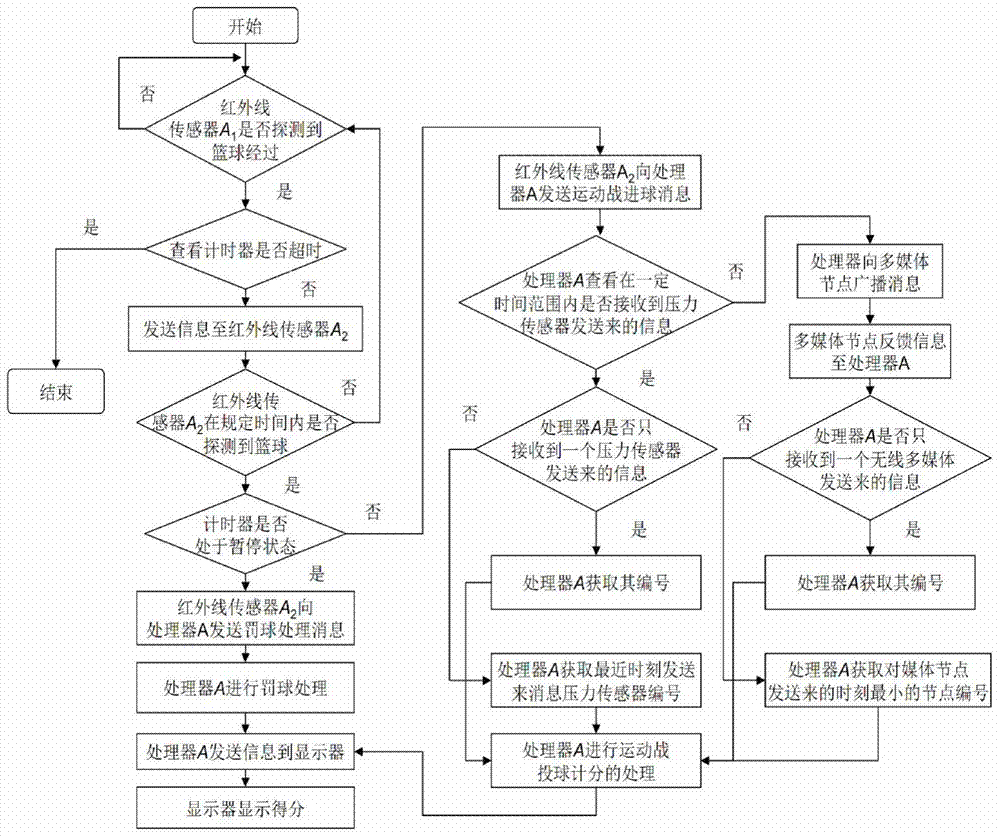

Auxiliary basketball shooting scoring system based on wireless sensing technology

InactiveCN104689550AReduce the use of manpower and material resourcesAvoid controversySport apparatusComputer scienceScoring system

The invention provides an auxiliary basketball shooting scoring system based on an infrared technology and a wireless sensing technology. The auxiliary basketball shooting scoring system utilizes infrared sensors, a pressure sensor and a wireless multi-media node to collect data and submit information to a miniature processor which processes the information and finishes the analysis and processing of the data so as to finish a scoring function. In the basketball shooting process, first, the variation of force is sensed by the pressure sensor, and the serial number of the pressure sensor and the moment that the sensor senses the variation of the force are submitted to the processor; then, when the upper and lower infrared sensors mounted on the same basket board sequentially detect that a basketball passes in a specified time range, information is transmitted to the processor, and corresponding scoring processing is carried out by the processor according to the information submitted by the infrared sensors, the pressure sensor and the wireless multi-media node. The method provides a novel thought for the research and development of the scoring system in a basketball match process, and effectively solves dispute problems caused by labor waste and manual scoring.

Owner:NANJING UNIV OF POSTS & TELECOMM

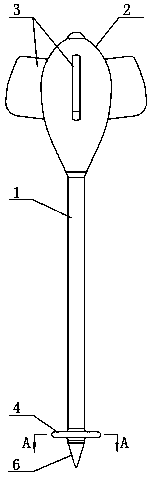

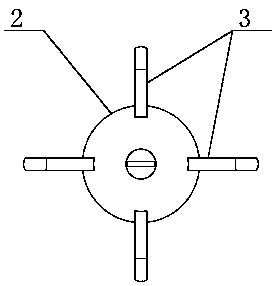

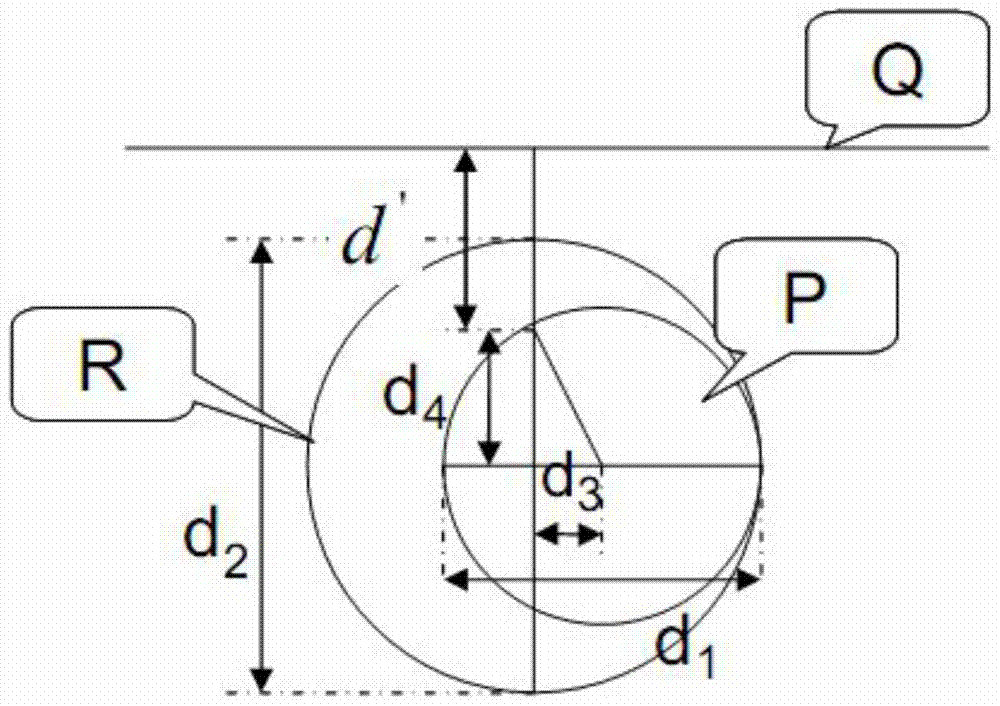

Method for measuring liquefaction resistance of offshore submarine sediments in situ

The invention discloses a method for measuring liquefaction resistance of offshore submarine sediments in situ. In the method, a measuring device is provided. The measuring process comprises a layingstep and a data acquisition step, in the laying step, S1, transporting the measuring device to a research target point position by an auxiliary boat, enabling a data module to work, connecting a lifting device with the measuring device through a mooring rope and a controllable hook, lifting the measuring device to a position above the research site position and keeping the measuring device to be vertical; S2, opening the controllable hook to enable the measuring device to penetrate into the offshore submarine sediments under the action of free gravity; in the recovering step, S3, after the measuring device penetrates into and is stable, recovering the measuring device through the lifting device; S4, acquiring penetration depth data and accelerated speed data. According to the method, the advantages of in-situ measuring methods such as SPT and CPT are synthesized, the liquefaction resistance of the offshore submarine sediments can be measured and evaluated effectively, and accurate dataand research basis are provided for prevention and control of coastal zone geological disaster.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

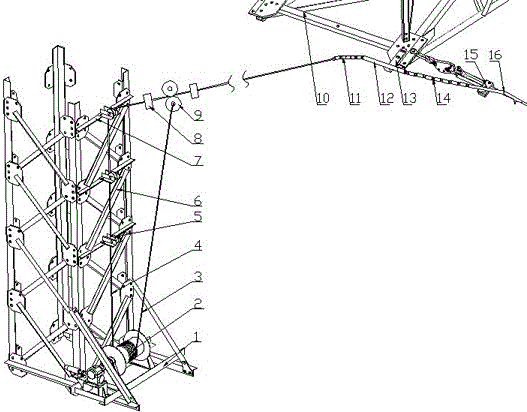

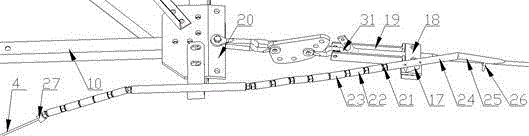

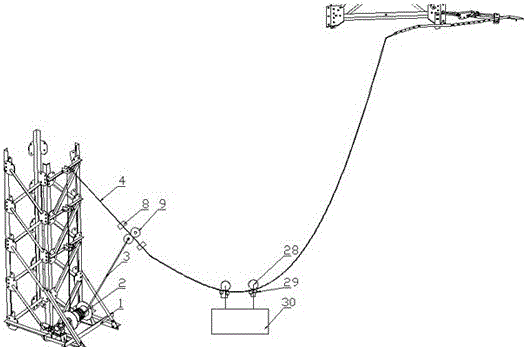

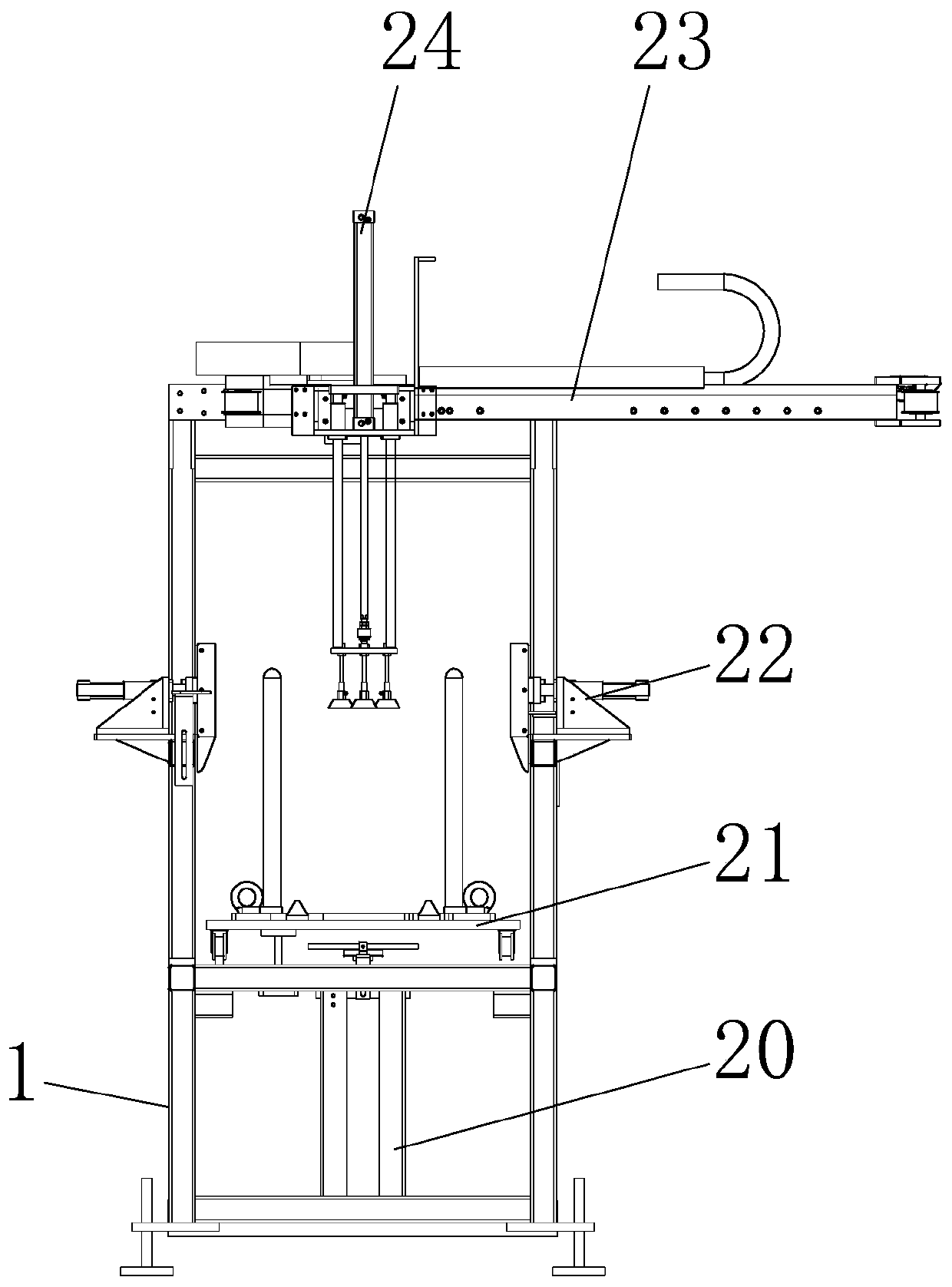

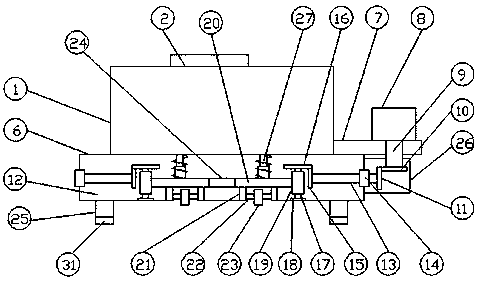

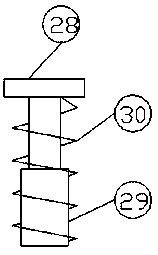

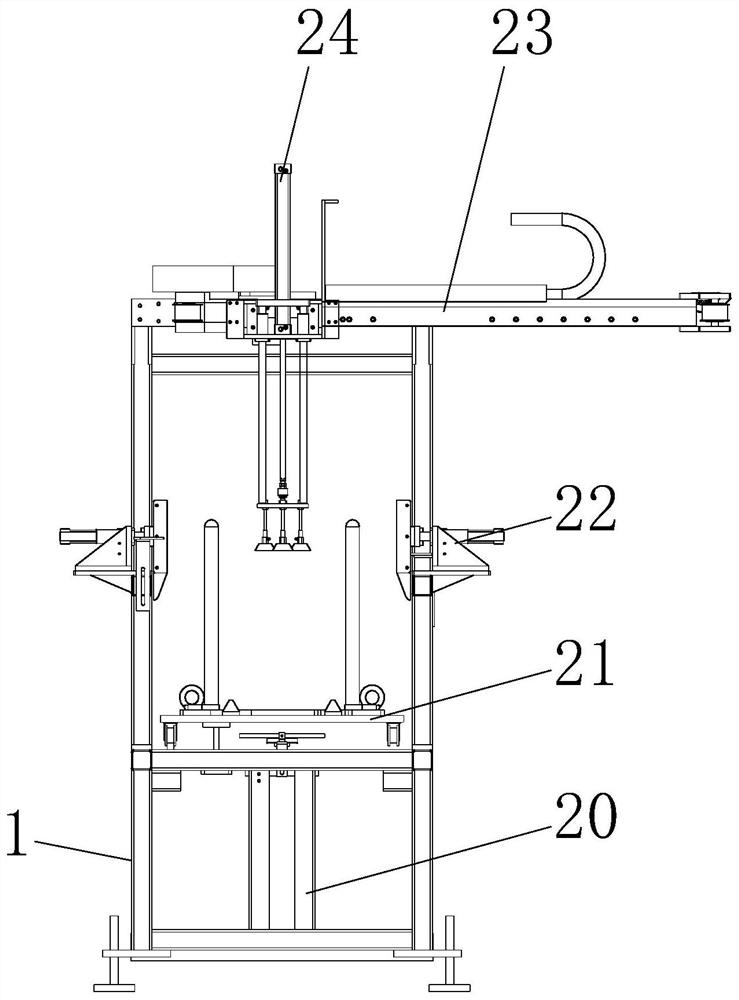

Automatic up-and-down device of line patrol robot of strain tower

ActiveCN105048336AReduce labor intensityEnsure personal safetyCranesApparatus for overhead lines/cablesPersonnel safetyEngineering

The invention relates to an automatic up-and-down device of a line patrol robot of a strain tower. The device comprises a foundation pile, a hoist, a stay wire and a guiding wire, the foundation pile includes a tower welded by angle iron, and is fixedly arranged on the ground separate from the head of the strain tower for certain distance, the hoist is fixed under the foundation pile, the stay wire and the guiding wire are wound at the two ends of a steel strand of the hoist respectively, the stay wire is led out of the side, close to the foundation pile, of the hoist, guided upwardly via fixed pulleys mounted on the foundation pile, and connected to the ground wire of the strain tower via a tower head bridging device mounted on the head of the strain tower, the guiding wire is led out of the other side of the hoist and fixed on a shaft of a group of movable pulleys, the movable pulleys is hung on the stay line outside the fixed pulley at the topmost end, and the stay wire at each side of the movable pulleys is provided with one stopper. According to the device, up and down of the line patrol robot does not need climbing the iron tower manually, labor and material are reduced, the labor intensity is reduced, the personnel safety is ensured, and the work efficiency is improved.

Owner:WUHAN UNIV +1

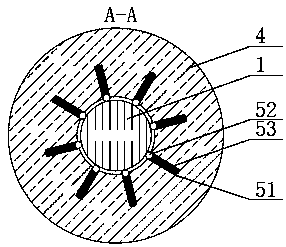

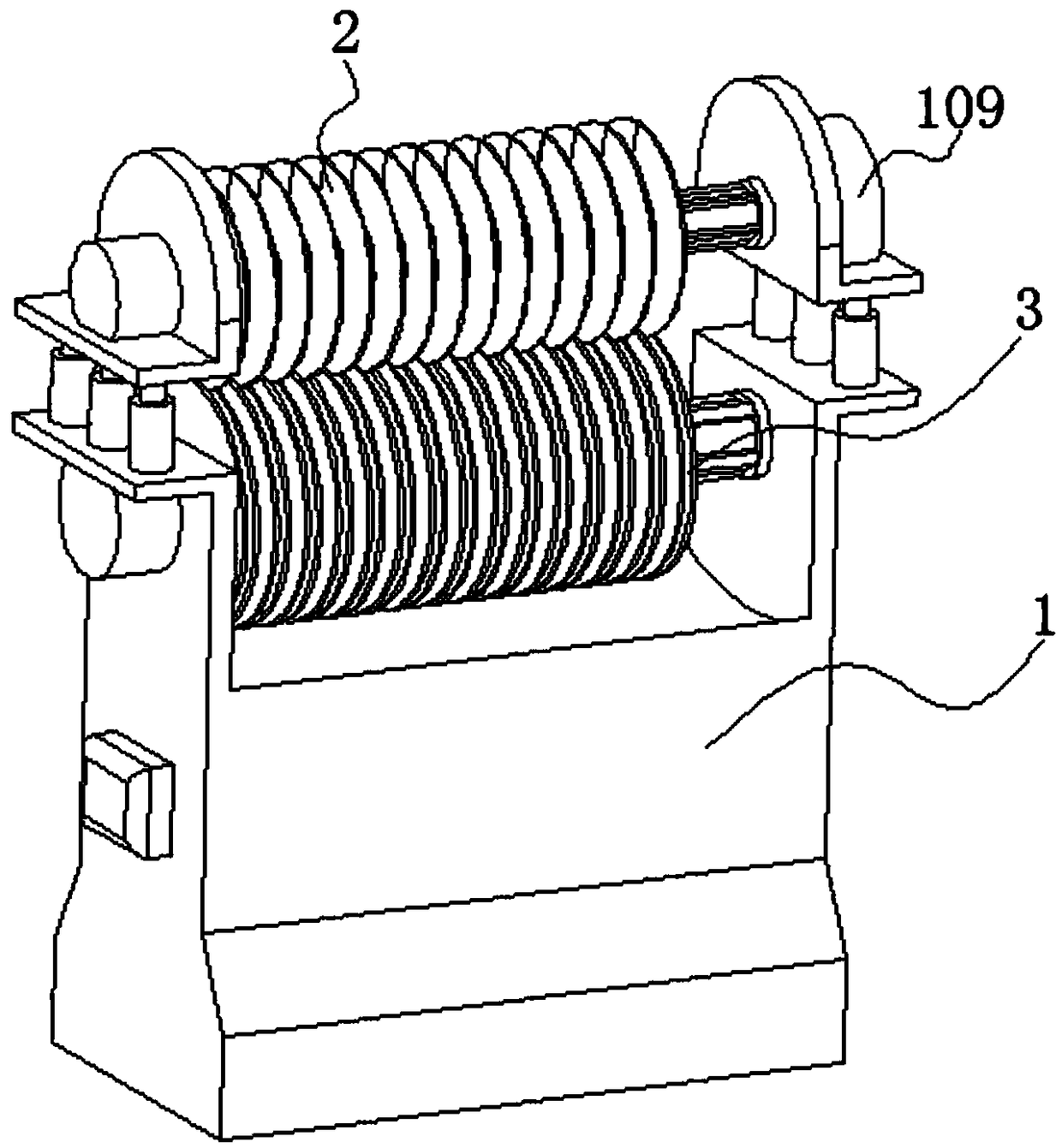

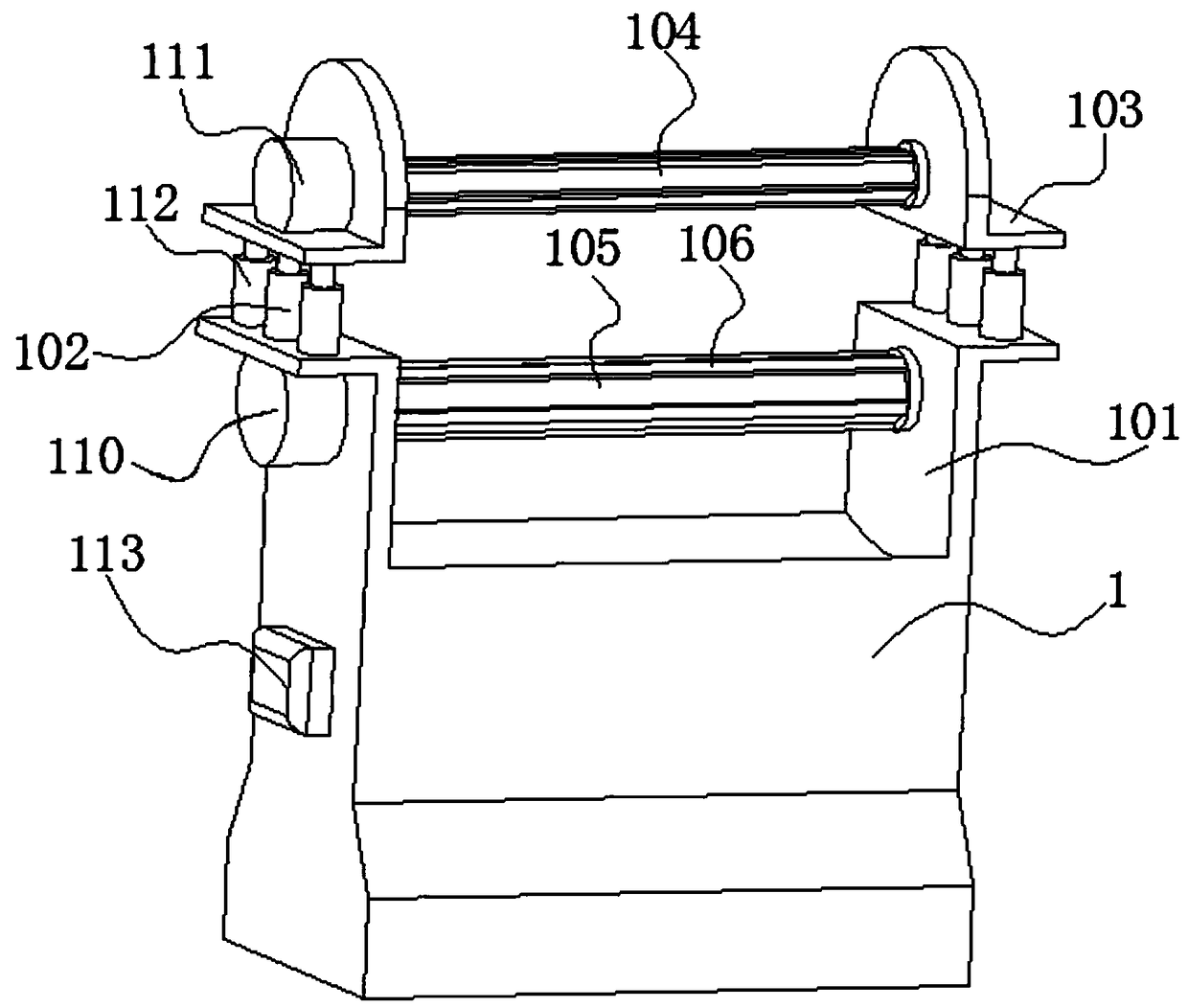

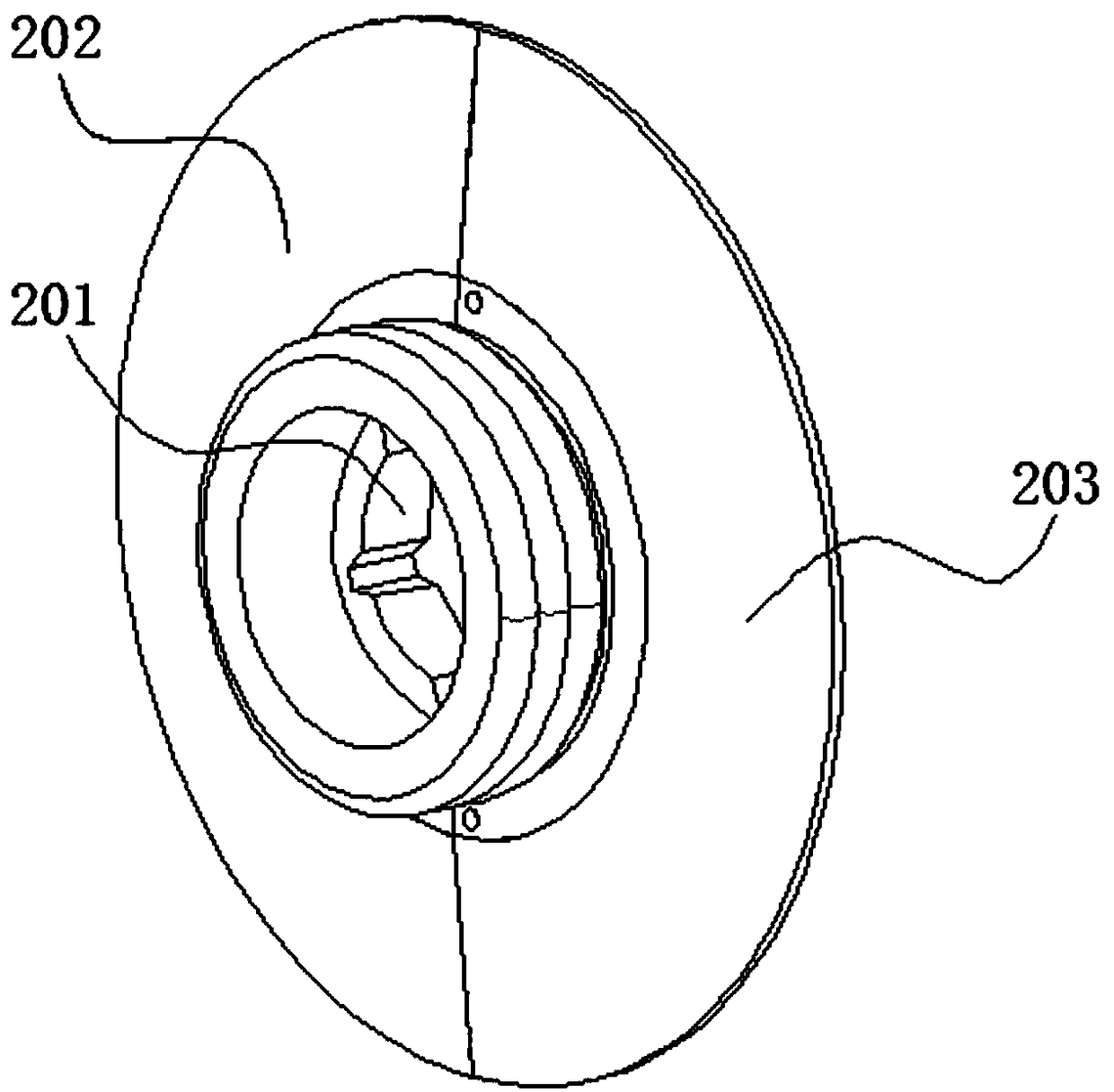

Longitudinal cutting slitting machine

The invention discloses a longitudinal cutting slitting machine and relates to the technical field of longitudinal cutting slitting machines. The machine includes a base, a group of first L-shaped plates are fixed to one surface of the base, a second L-shaped plate is fixed to one surface of each first L-shaped plate through an air cylinder, a first rotating shaft is rotatably connected between the two first L-shaped plates, and a second rotating shaft is rotatably connected between the two second L-shaped plates; five guiding strips are fixed to the circumferential side faces of the first andsecond rotating shafts. First blades and second blades are inserted into annular groove openings through running of the air cylinder, and gas is introduced into a retractable gasbag by separately utilizing an air pump, a diversion pipe and hoses; the gas feeding amount of the hoses is controlled through an electric flow valve to maintain the amount of the gas in the retractable gasbag uniform, and therefore the distance between base rings is adjusted; when the base rings move, a cutter groove disc moves along with the movement of a cutter disc, and the problems that the distance among bladesis inconvenient to adjust by existing longitudinal cutting slitting machines and the blades are inconvenient to install and dismantle are solved.

Owner:FOSHAN UNIVERSITY

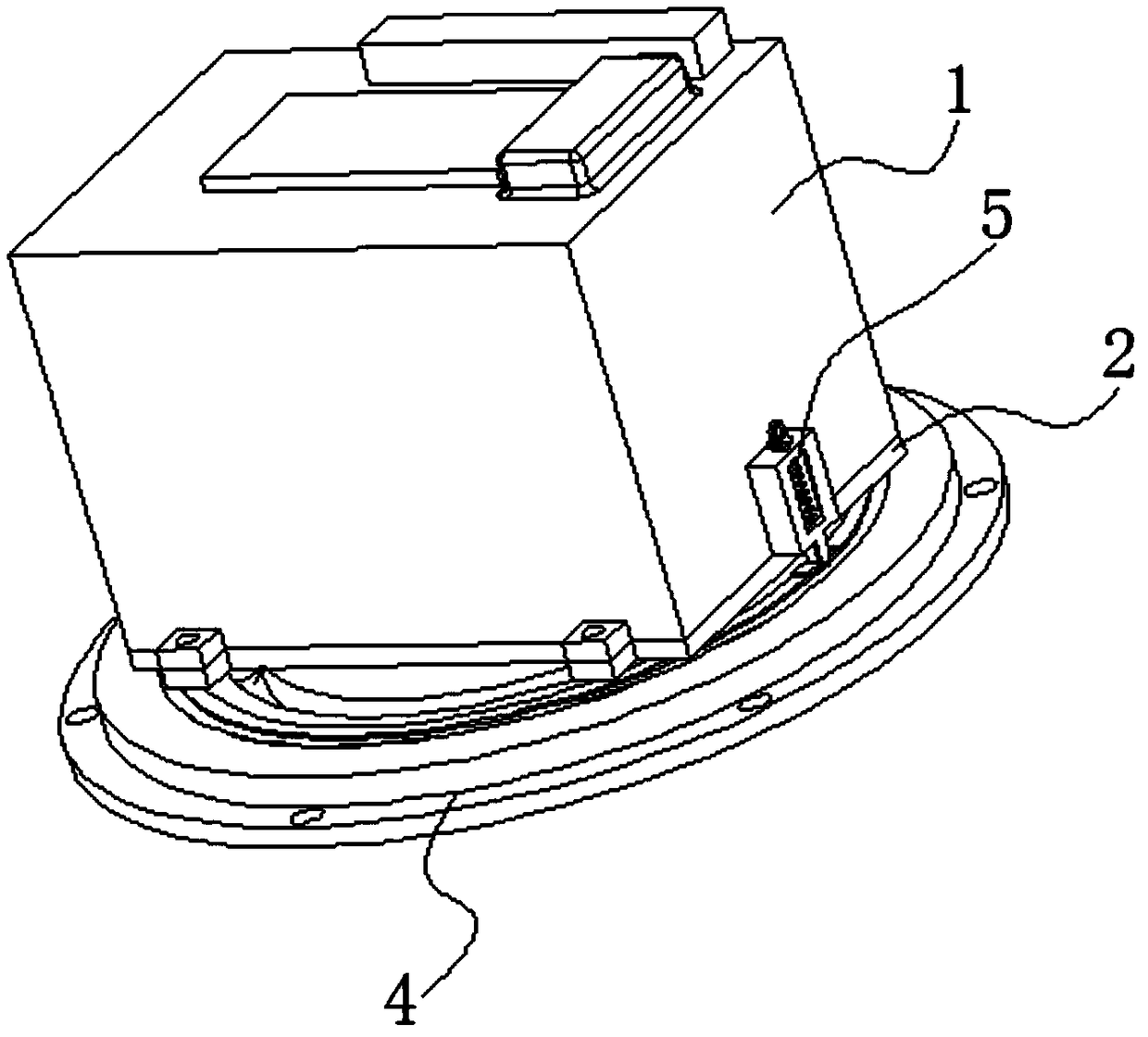

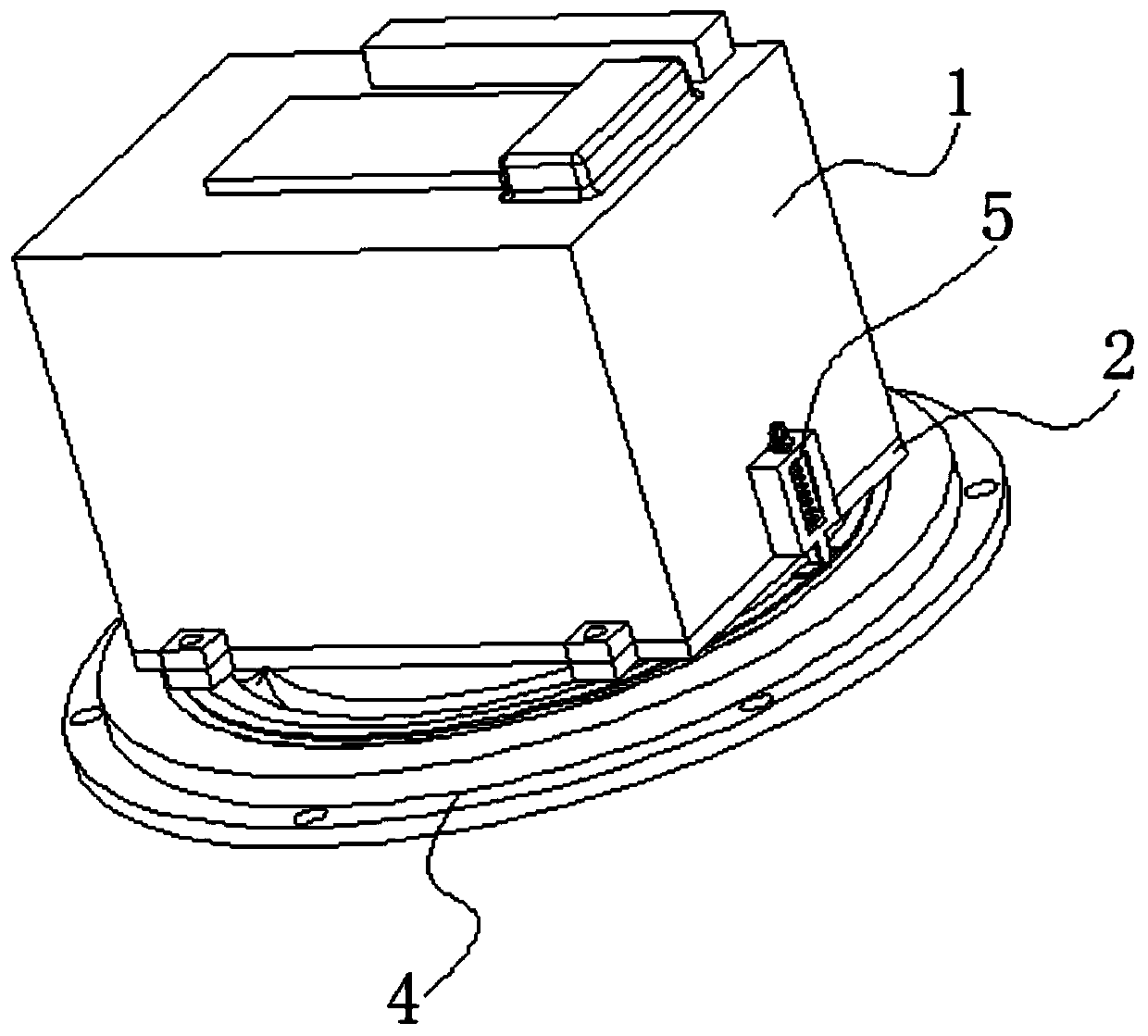

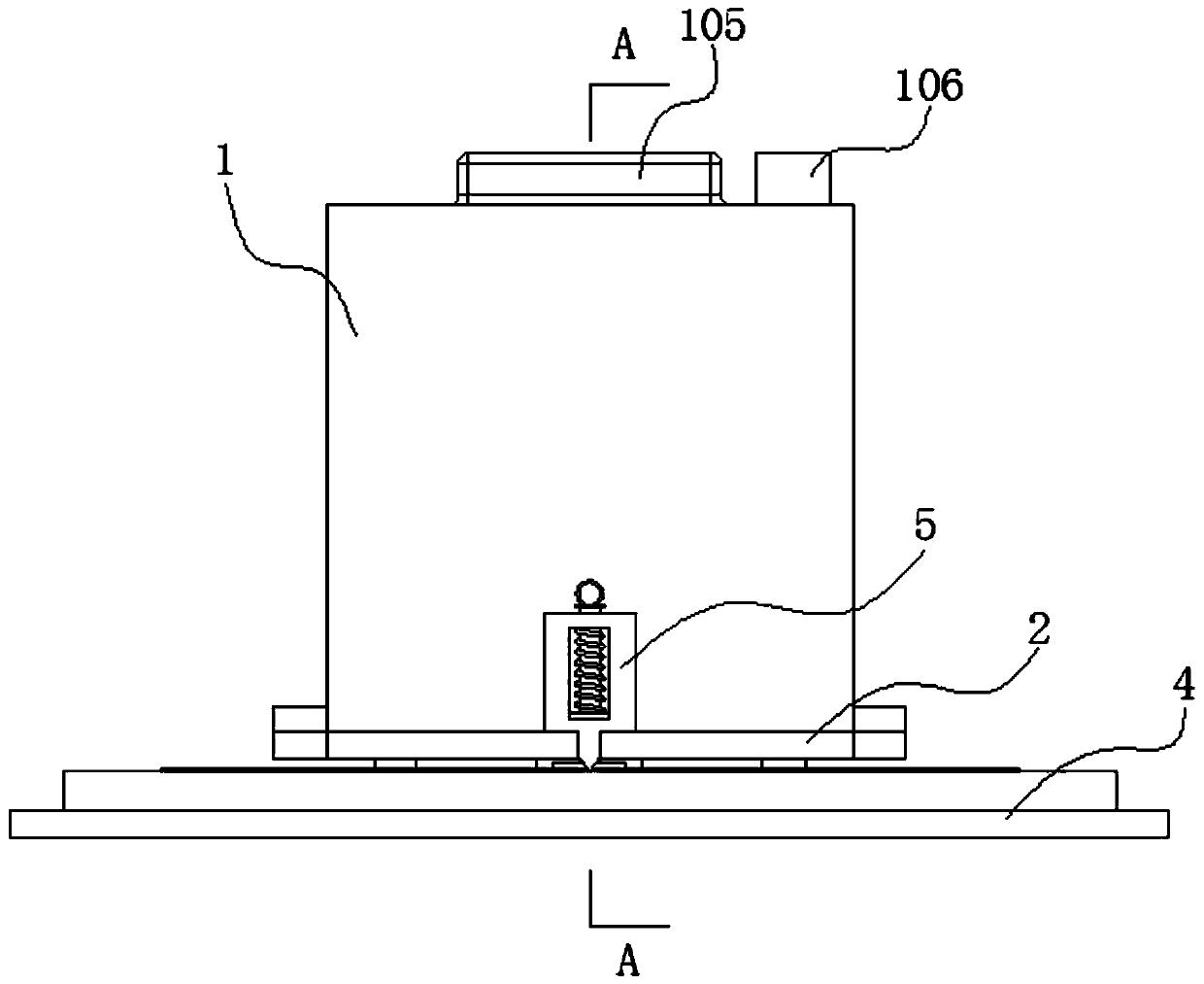

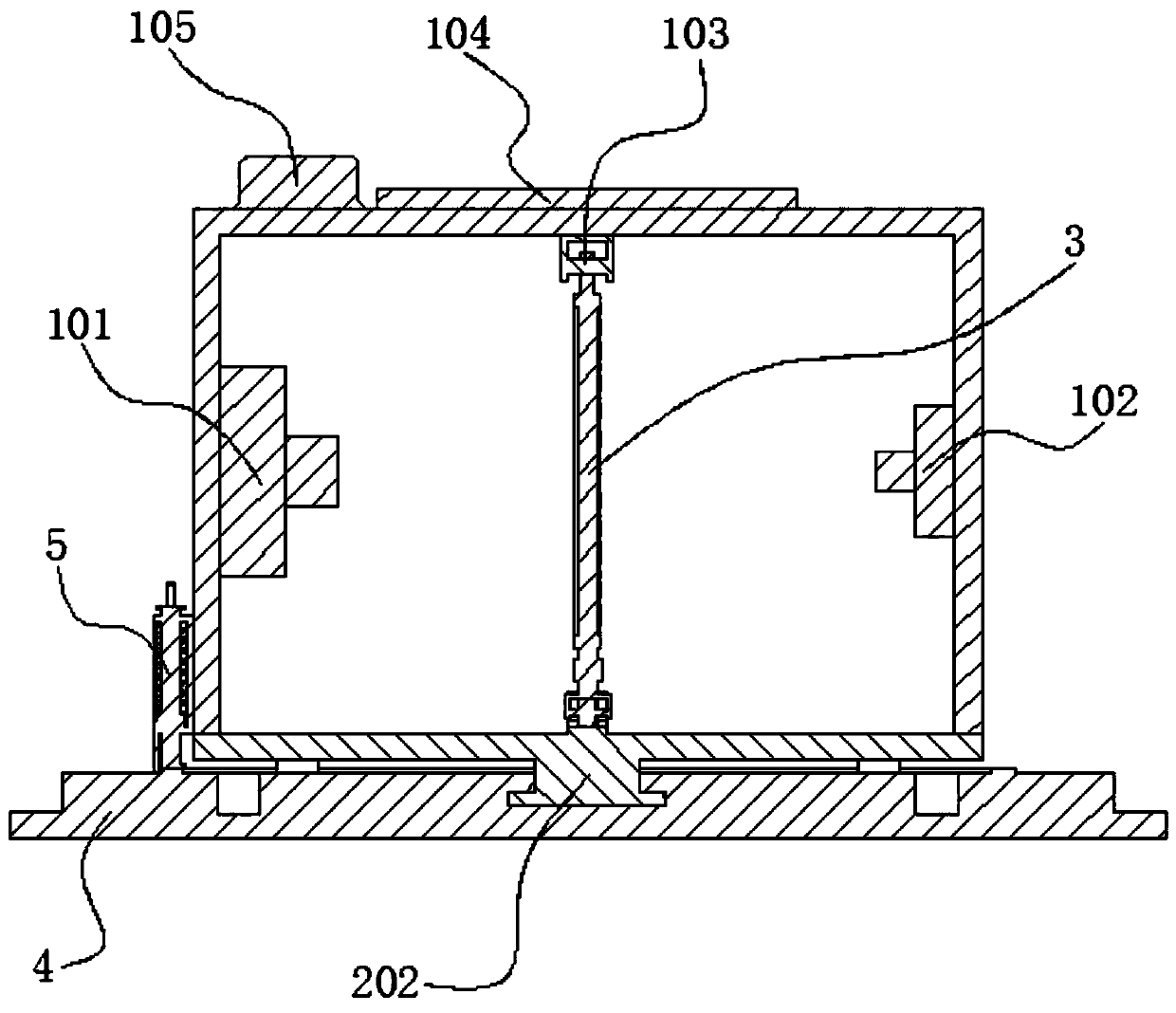

Photoelectric type angle measuring device

The invention discloses a photoelectric type angle measuring device, and relates to the technical field of angle measurement. The photoelectric type angle measuring device comprises a box body and a bottom cover. The bottom of the bottom cover is rotatably connected with an annular base, and a positioning device is fixed to the peripheral side surface of the box body. A lase emitter and a luminometer are separately fixed to one opposite inner wall of the box body, and an optical filter assembly is rotatably connected to the top of the inner wall of the box body through a hinge seat. The optical filter assembly comprises a optical filter, and a fixing ring is fixed to the peripheral side surface of the optical filter. According to the photoelectric type angle measuring device, the box bodyis rotated through the cooperation of a limiting block, a limiting notch, a sliding rod and an annular notch, the angle to be measured again is selected through the relative positions of a scale ringand a scale, the relative positions of the bottom cover and the annular base are limited through the positioning device, angle values of different angles of an object can be quickly and accurately measured, and the problem that the measurement is inaccurate after the measurement angle of an existing angle measuring device is changed is solved.

Owner:李成山

Novel textile washing equipment

InactiveCN108330635AImprove washing effectImprove washing efficiencyMechanical cleaningSucessive textile treatmentsIntegrated operationsMaterial resources

The invention discloses novel textile washing equipment. The novel textile washing equipment comprises a machine body and a pedestal which is arranged at the bottom of the machine body and is arrangedin a bilaterally symmetrical mode; compressing and transmitting assemblies are symmetrically arranged on the left end face and the right end face of the machine body; each compressing and transmitting assembly comprises an opening cavity with an outward opening; two transmitting rolling wheels which are bilaterally symmetrical are rotatably arranged at the lower part of the opening cavity througha first rotating shaft; and a lifting and sliding groove is formed in the end wall of the inner side of the upper part of the opening cavity. The novel textile washing equipment can realize clamping,tensioning, transmitting, washing and drying integrated operation of textile cloth, realizes automatic washing operation of the textile cloth, greatly improves the washing effect and the washing efficiency of the textile cloth, has a good washing effect, avoids the phenomenon that the textile cloth is wrinkled in the washing process, is simple in structure, convenient and rapid in operation and low in production cost, greatly reduces use of manpower and material resources, simplifies the washing step of the textile cloth and reduces the washing time of the textile cloth.

Owner:陈李月

Combined-type ecological floating bed suitable for environmental restoration of urban riverway environment

InactiveCN108361141AReduce consumptionAchieve self-sufficiencyWater resource protectionWaterborne vesselsExternal energyBiological filter

The invention discloses a combined-type ecological floating bed suitable for environmental restoration of the urban riverway environment. The combined-type ecological floating bed structurally comprises two or more upper plant growing basins, an upper floating plate, two floating buckets, an algae-inhibiting filter material plate, two biological filter material plates, a connecting plate, illumination lamps, connecting columns, an autonomous power generation device and lower plant growing basins. The upper plant growing basins are evenly distributed on the upper surface of the upper floating plate at equal intervals; the two floating buckets are connected to the left and right ends of the upper floating plate in a glued mode; the algae-inhibiting filter material plate is buckled on the lower portions of the floating buckets through buckles; the two biological filter material plates are horizontally fixed to the lower portion of the algae-inhibiting filter material plate and are mutually parallel; and the connecting plate is fixed to the lower portions of the biological filter material plates through screws. The water pressure can be converted into driving energy of equipment by thearranged autonomous power generation device, mechanical energy of water is converted into electric energy to be stored, self-sufficiency of the equipment is achieved, consumed external energy is less, use of manpower and material resources is reduced, and resources and the cost are more saved.

Owner:谢幼环

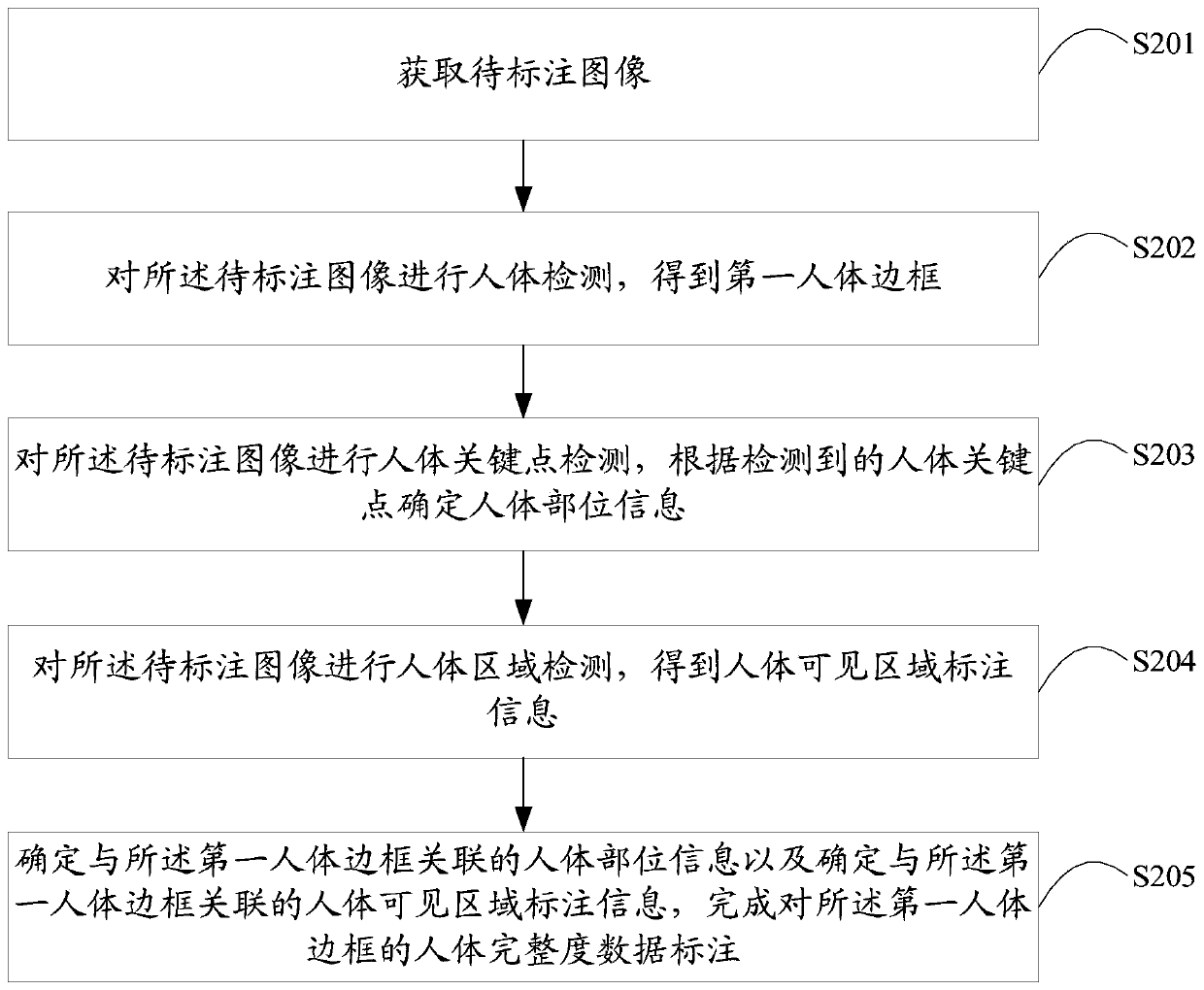

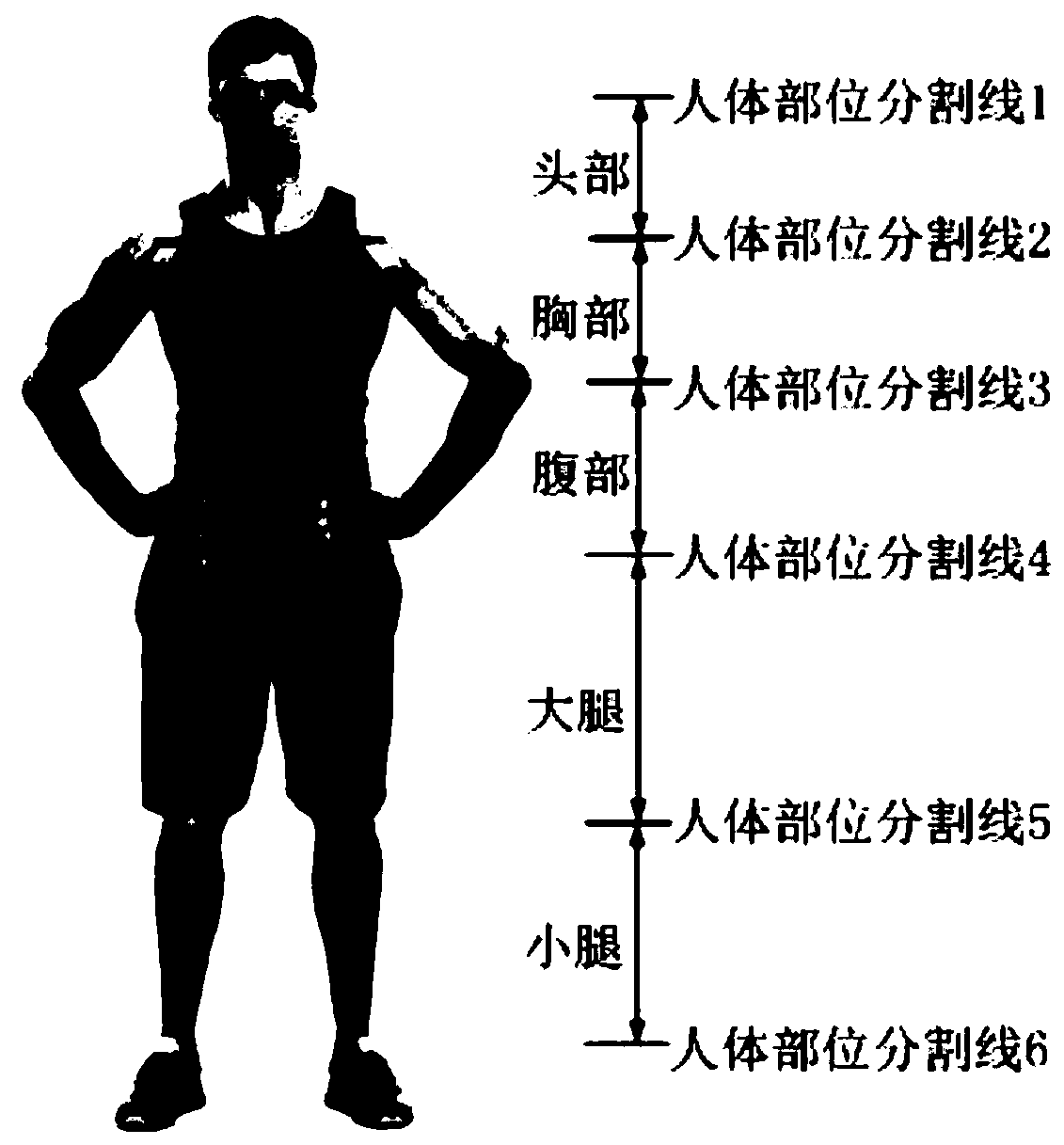

Human body integrity data labeling method and device and terminal equipment

ActiveCN110852162AReduce the use of manpower and material resourcesReduce usageImage enhancementImage analysisHuman bodyRadiology

The invention is suitable for the technical field of data processing, and provides a human body integrity data labeling method and device and terminal equipment. The method comprises the steps of acquiring a to-be-labeled image; performing human body detection on the to-be-labeled image to obtain a first human body frame; performing human body key point detection on the to-be-labeled image, and determining human body part information according to the detected human body key points; performing human body region detection on the to-be-labeled image to obtain human body visible region labeling information; and determining human body part information associated with the first human body frame and human body visible region labeling information associated with the first human body frame, and completing human body integrity data labeling of the first human body frame. The human body integrity data labeling method and device can solve the problems that in the prior art, human body integrity data labeling is conducted in a manual labeling mode, a large number of manpower and material resources are consumed, labeling time is long, errors are prone to occurring, and rapid iteration of products is not facilitated.

Owner:SHENZHEN INTELLIFUSION TECHNOLOGIES CO LTD

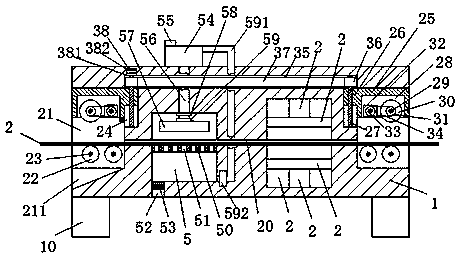

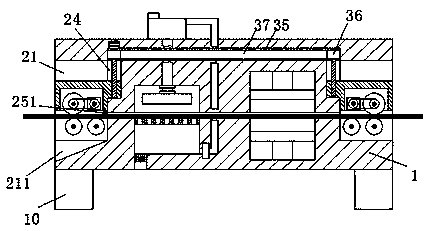

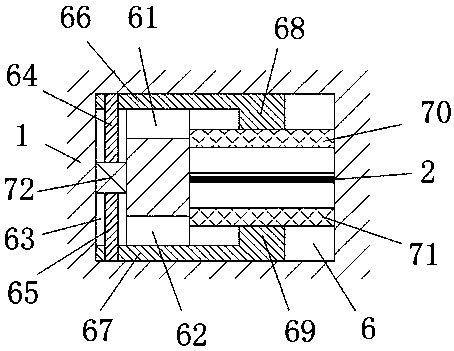

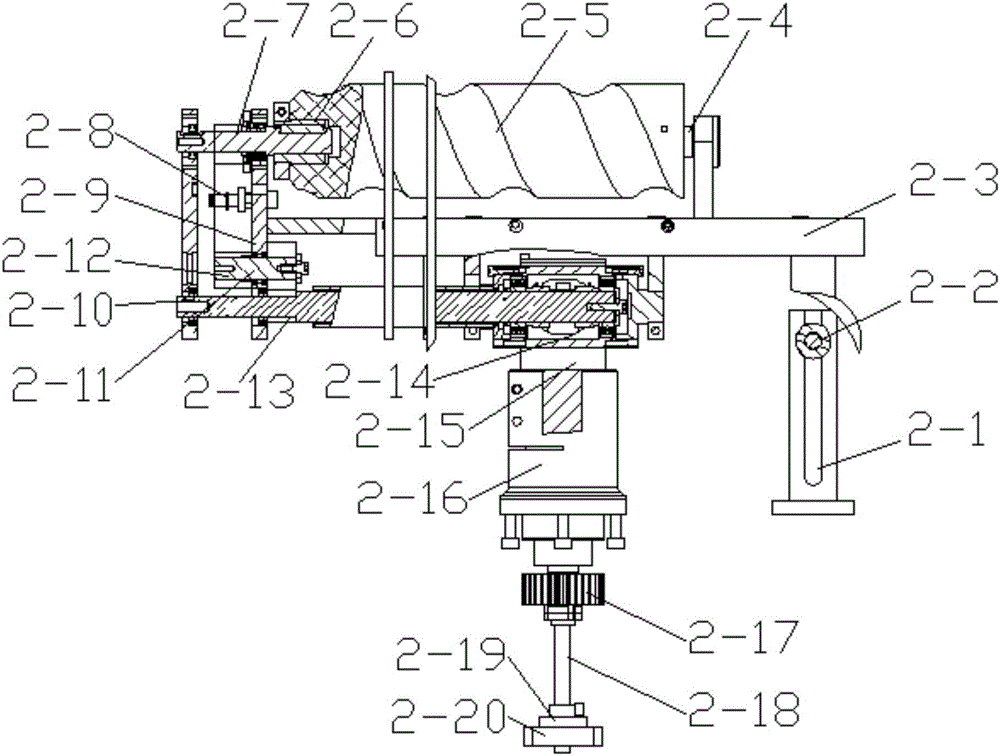

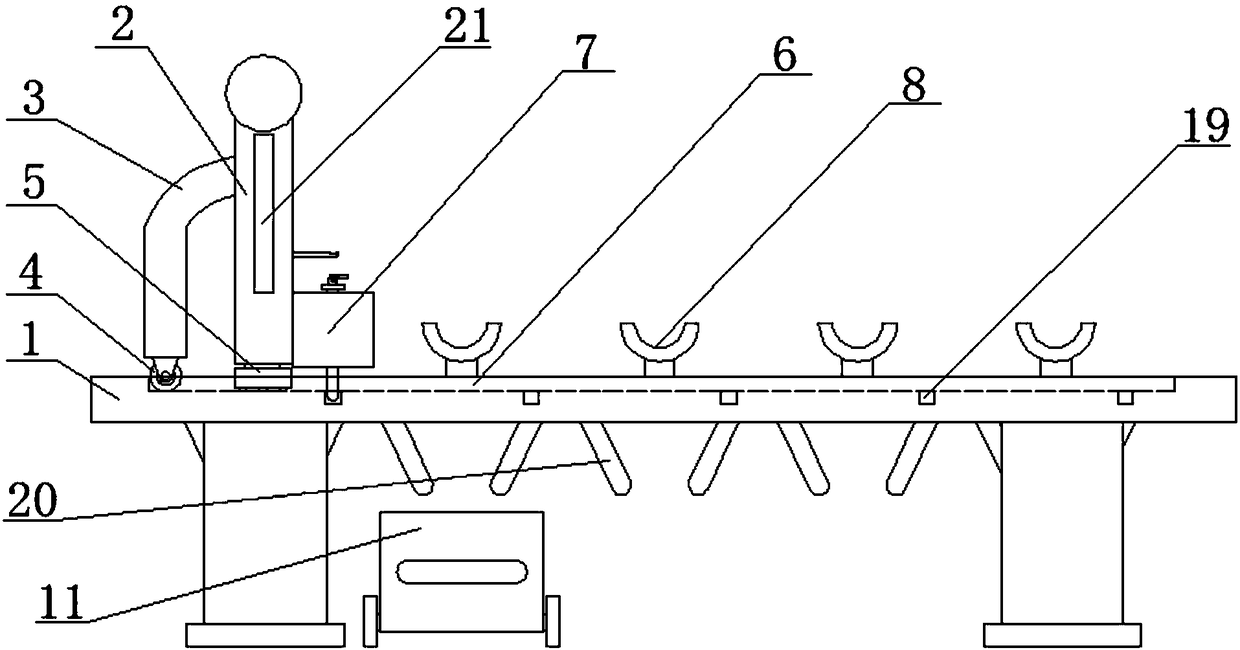

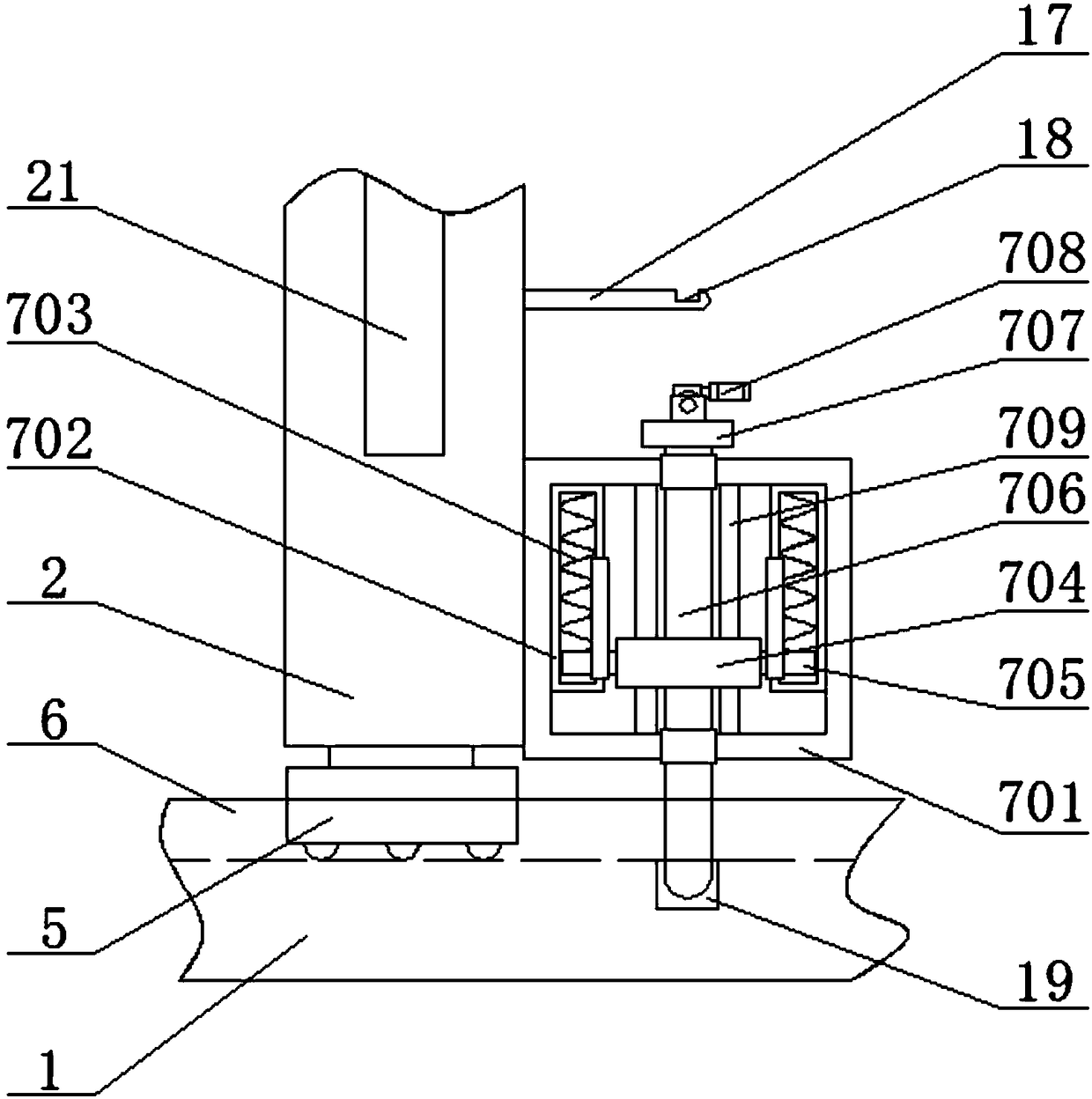

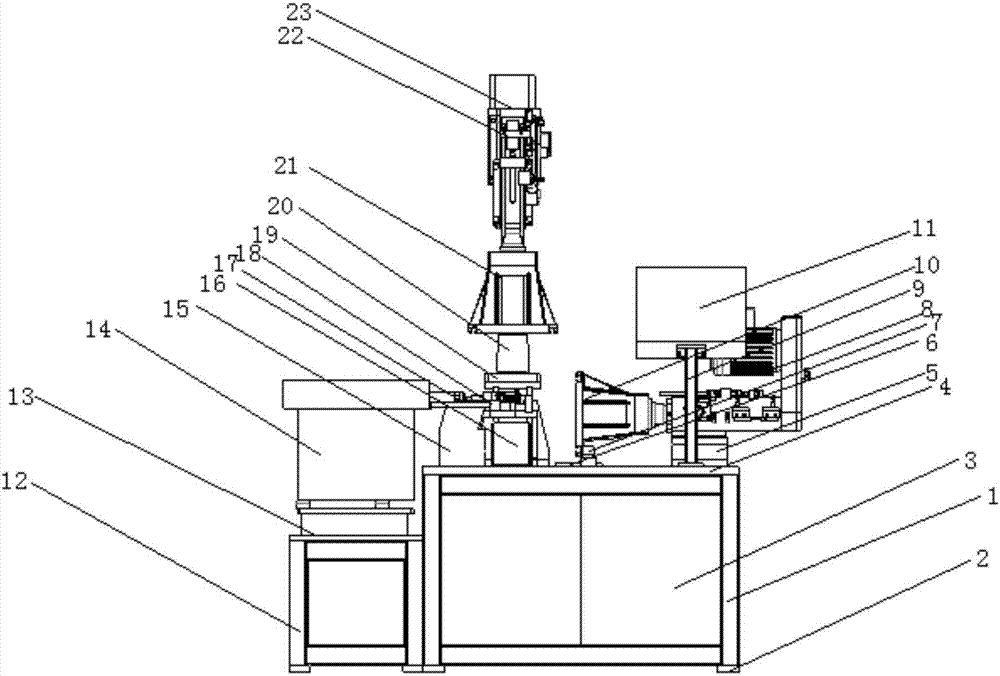

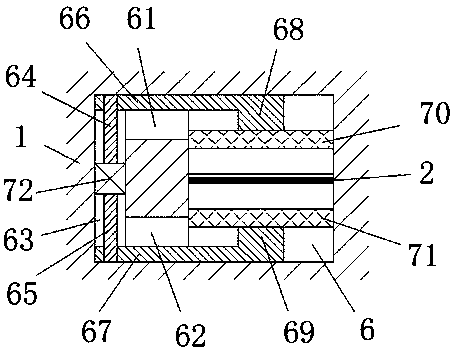

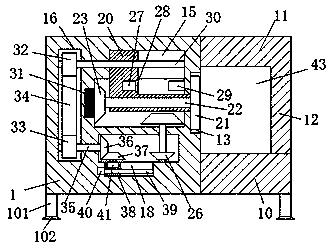

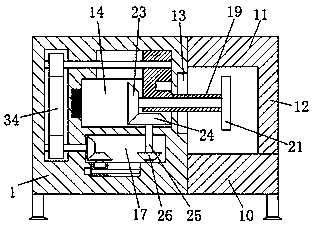

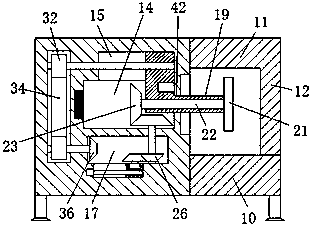

Inner-stopper screw cap production device for press wood stoppers

InactiveCN106698289ASave manpower and material resourcesHigh degree of automationThreaded caps applicationStopper securingEngineeringMaterial resources

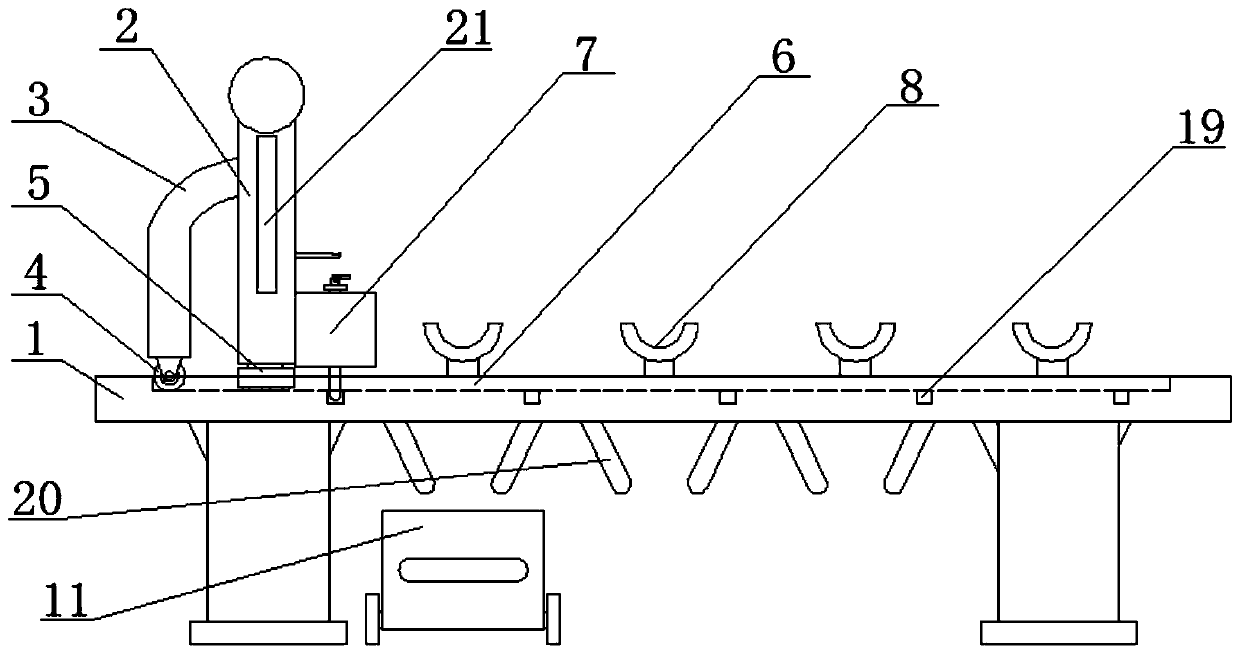

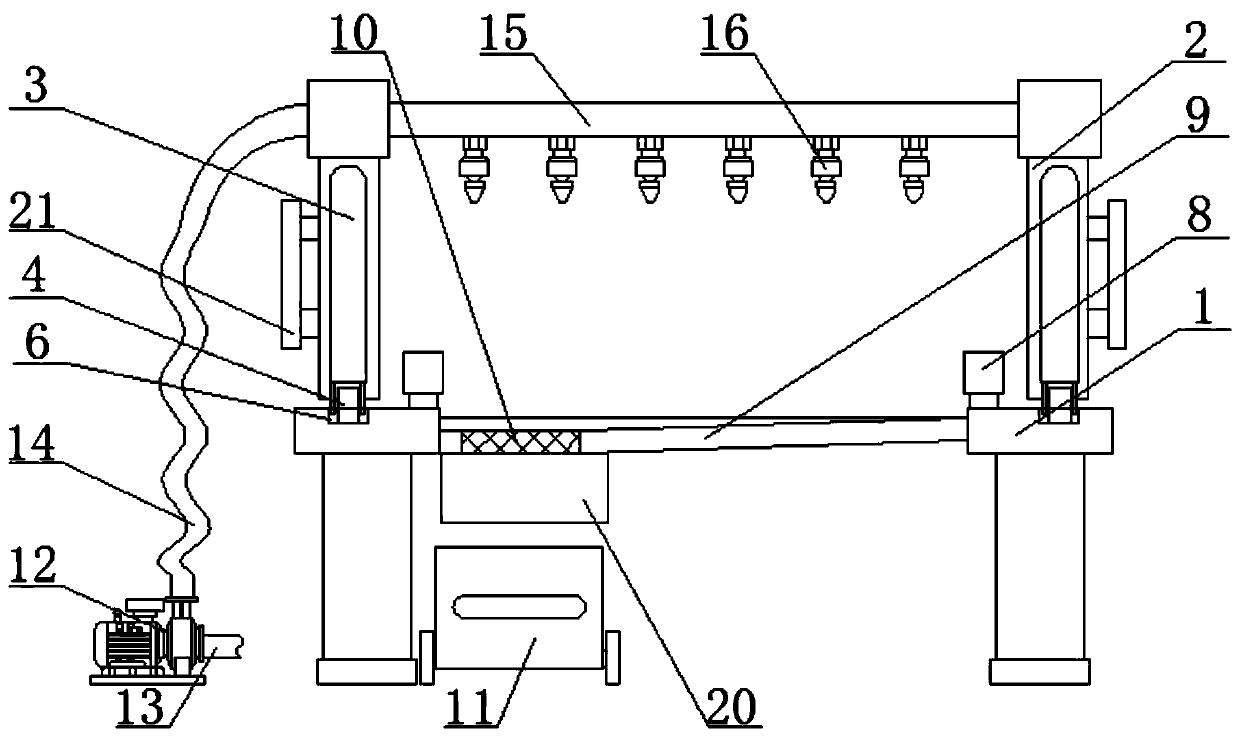

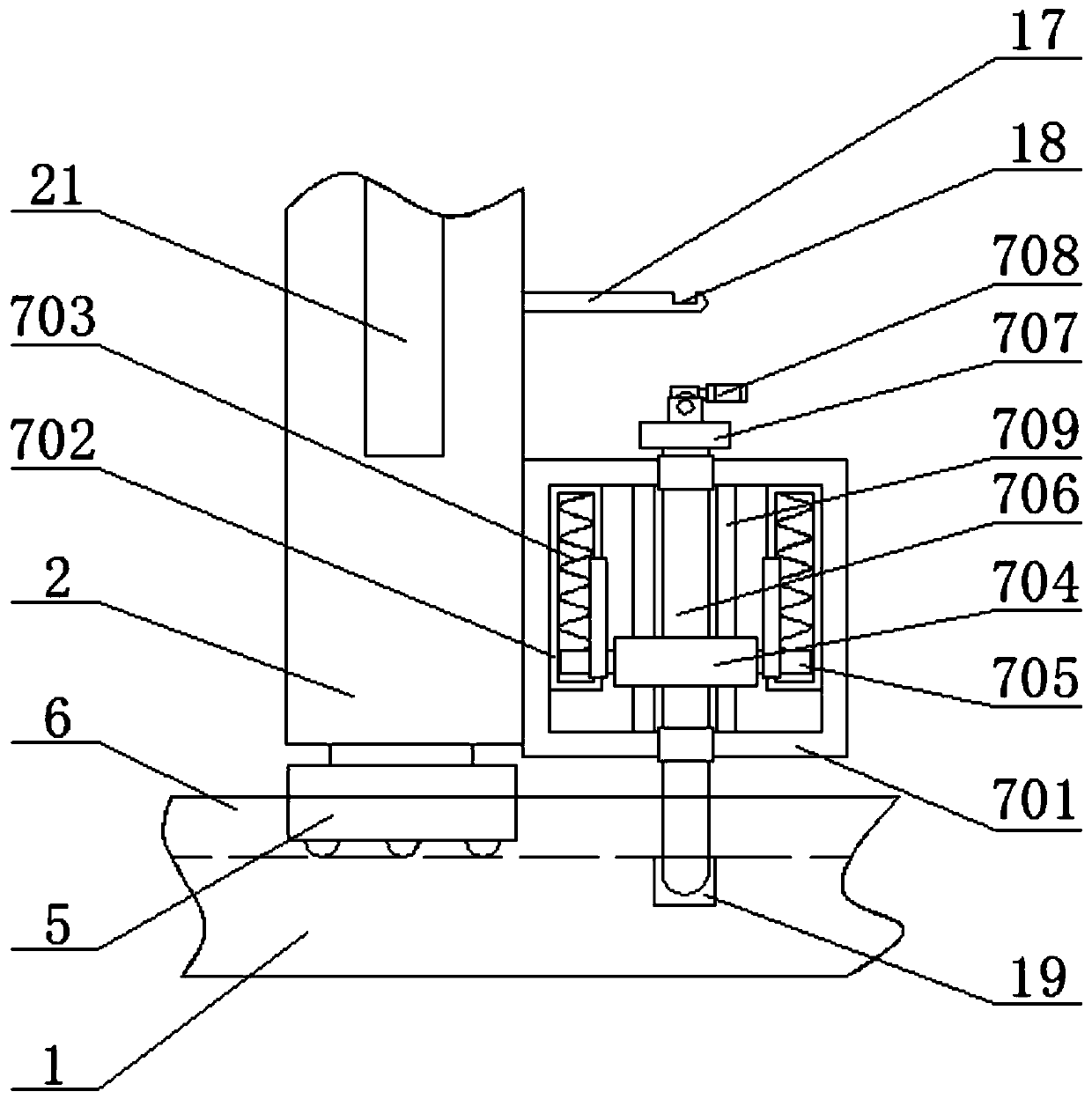

The invention discloses an inner-stopper screw cap production device for press wood stopper. The inner-stopper screw cap production device comprises a conveying belt and a bottle-dividing screw mechanism, the conveying belt is arranged in a working table, a driving gear on a motor output shaft of the conveying belt at the bottom of the working table is connected with a driven gear on a rotating shaft of the conveying belt in a meshed rotation manner, the bottle-dividing screw mechanism is mounted on one side of a rotating type press wood stopper mechanism, a star thumbwheel connected at the tail portion of the bottle-dividing screw mechanism is arranged under a gas claw gripper of a rotating disc type wood stopper screwing mechanism, the rotating disc type wood stopper screwing mechanism and a wood stopper dropping vibrating plate are connected through a guide rail, a press wood stopper machine is connected with an inner-stopper dropping vibrating plate through a guide rail, a bottle cap lifter is mounted on the right side of the inner-stopper dropping vibrating plate, and a bottle cap lifter seat fixed under the bottle cap lifter is located under the conveying belt. By the arrangement, wood stoppers can be pressed and screwed to be capped at one step, manpower and material resources are reduced, and the inner-stopper screw cap production device is high in automation degree, low in cost and easy to maintain.

Owner:GUANGZHOU BRUIM PACKAGING MACHINERY

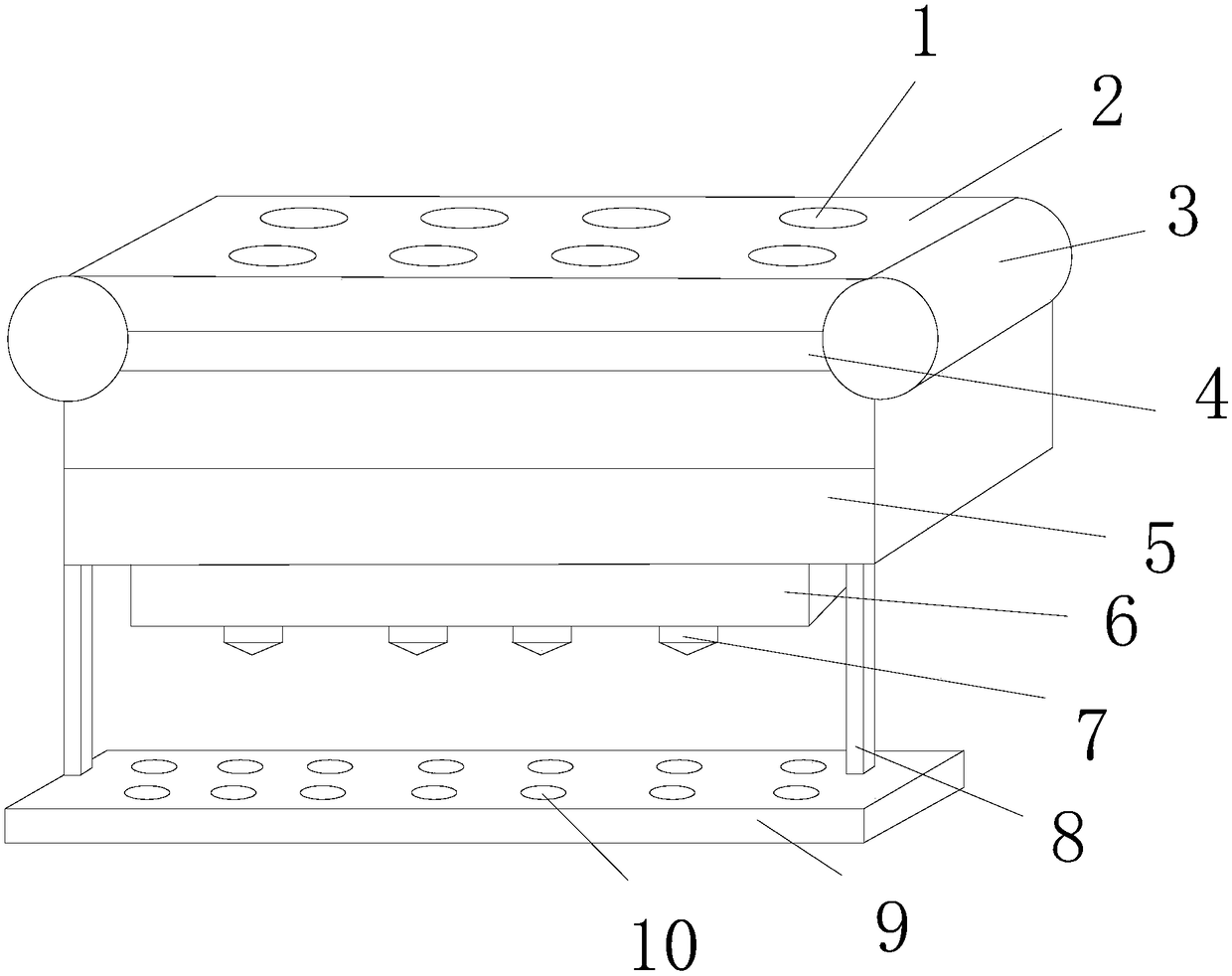

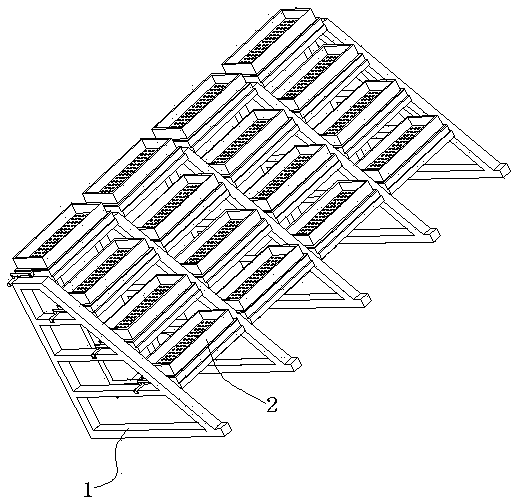

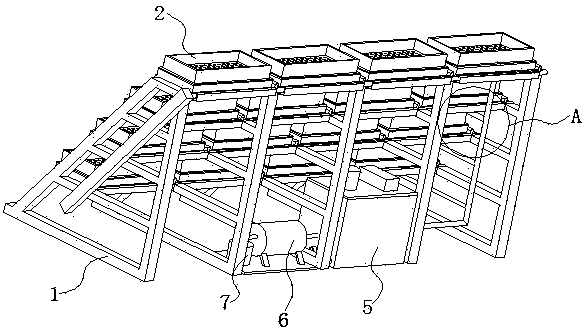

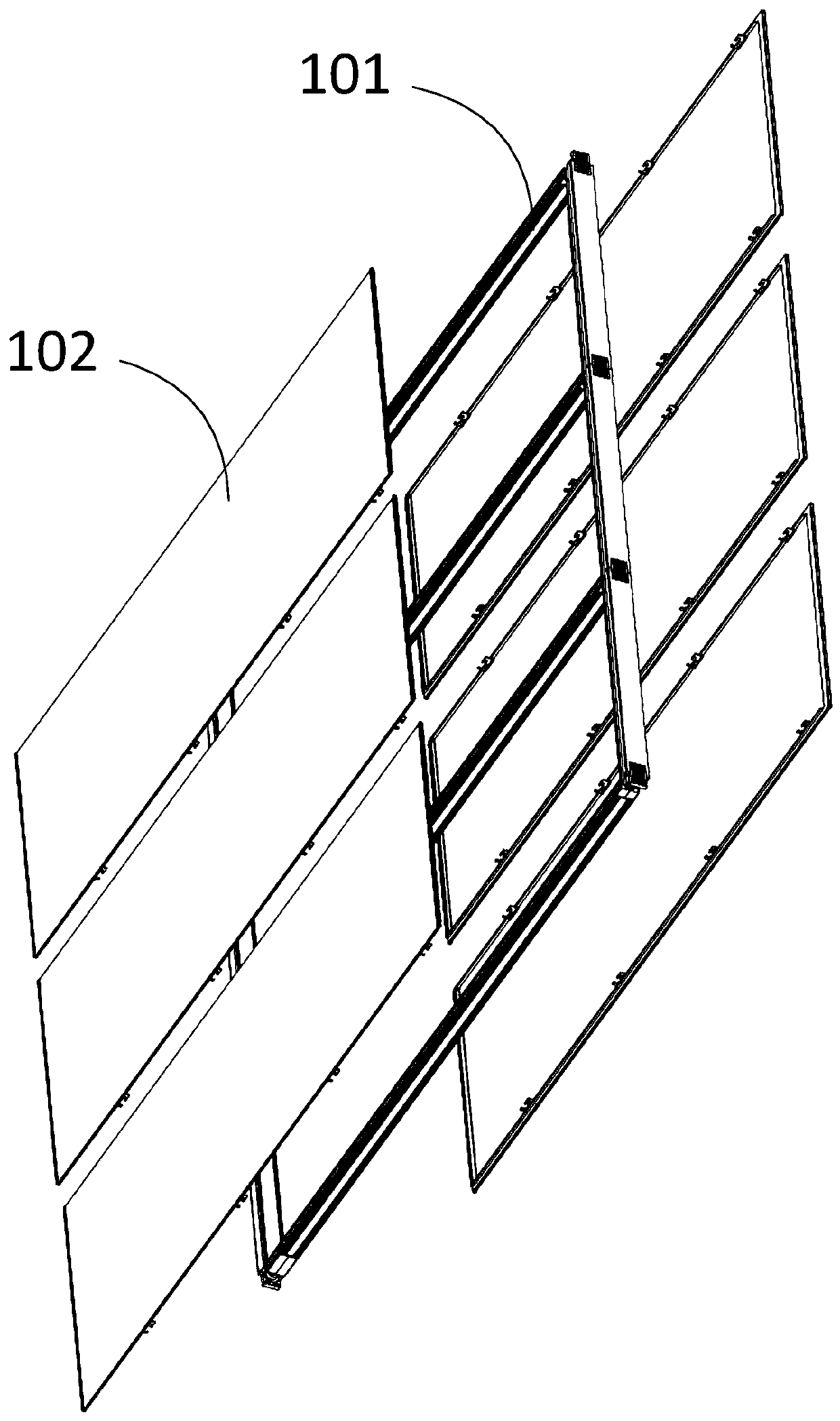

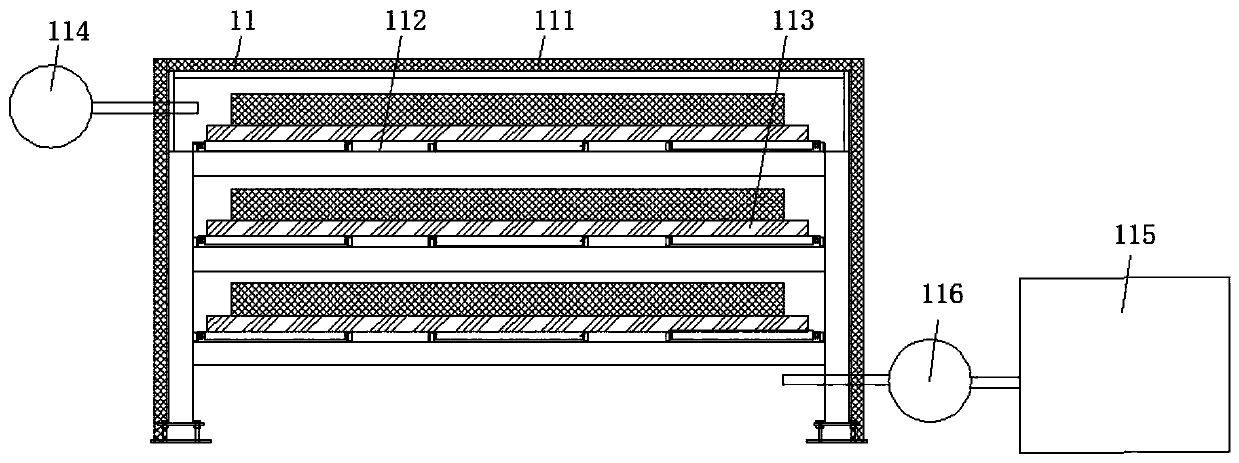

Water culture planting frame based on wheat culture

InactiveCN108575724AAvoid affecting the breeding effectReduce the use of manpower and material resourcesAgriculture gas emission reductionCultivating equipmentsFrame basedEngineering

The invention discloses a water culture planting frame based on wheat culture and relates to the technical field of wheat culture. The water culture planting frame disclosed by the invention comprisesa frame body and a culture device and also comprises a water pumping mechanism and a water inlet assembly, wherein the frame body comprises five support frames, the cross section of each support frame is of a right-angle trapezoidal structure, four groups of transverse rods are fixedly arranged on the five support frames in a penetrated mode, and the four groups of transverse rods are linearly arranged obliquely. The water pumping mechanism is used for pumping a nutrient solution inside each water culture box into a charging box, a water pumping pipeline is used for discharging the nutrient solution inside the charging box into each water culture box to form a circulation of the nutrient solution, simultaneously, an EC sensor inside the charging box is utilized for detecting the nutrientconcentration of the nutrient solution, and a control device is utilized for controlling a third electric flow valve on a discharging pipe of a liquid storing box to be opened and closed, thereby solving the problem that an existing water culture planting frame for wheat culture does not have a function of automatically adding the nutrient solution so that manpower and material resources are excessively wasted.

Owner:LIANYUNGANG ACAD OF AGRI SCI

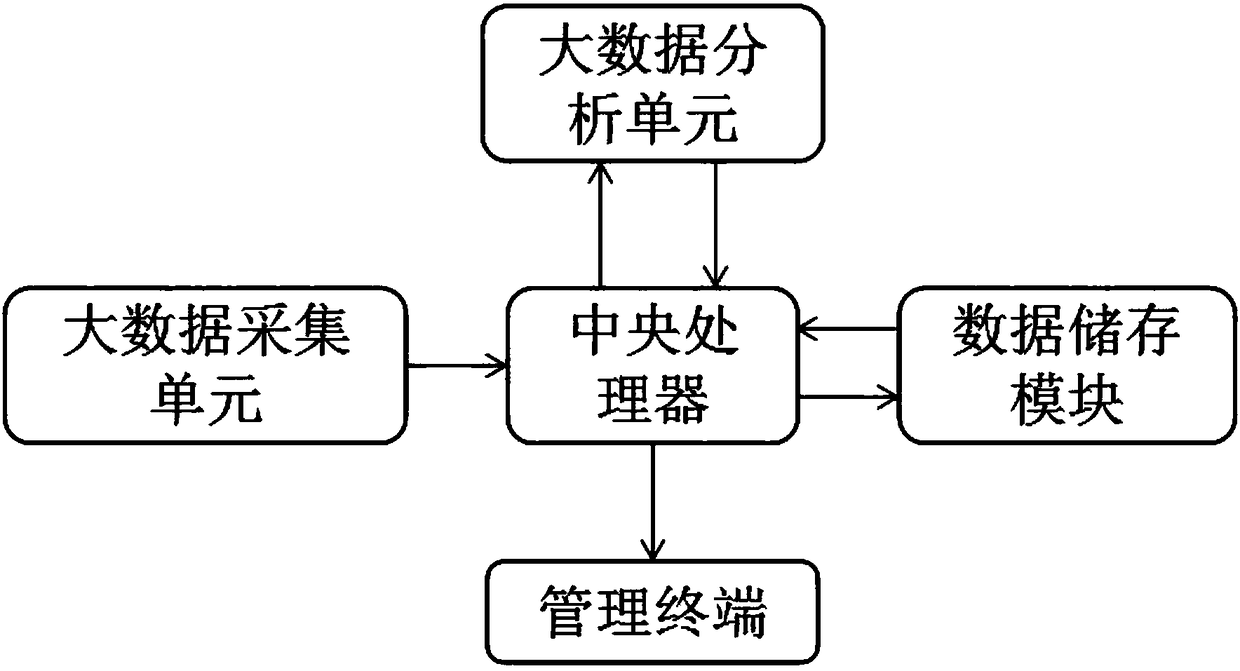

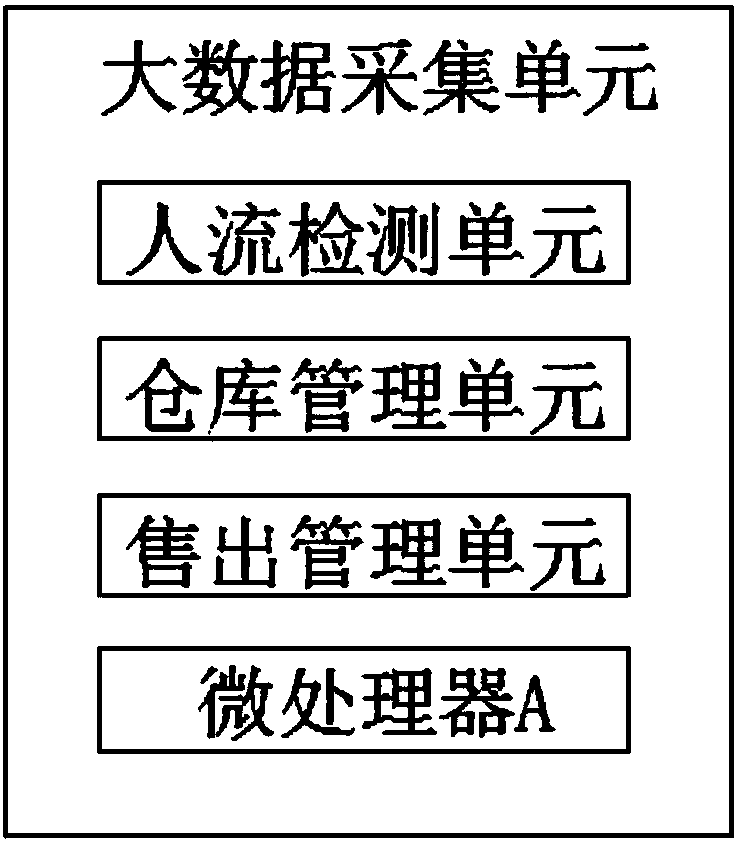

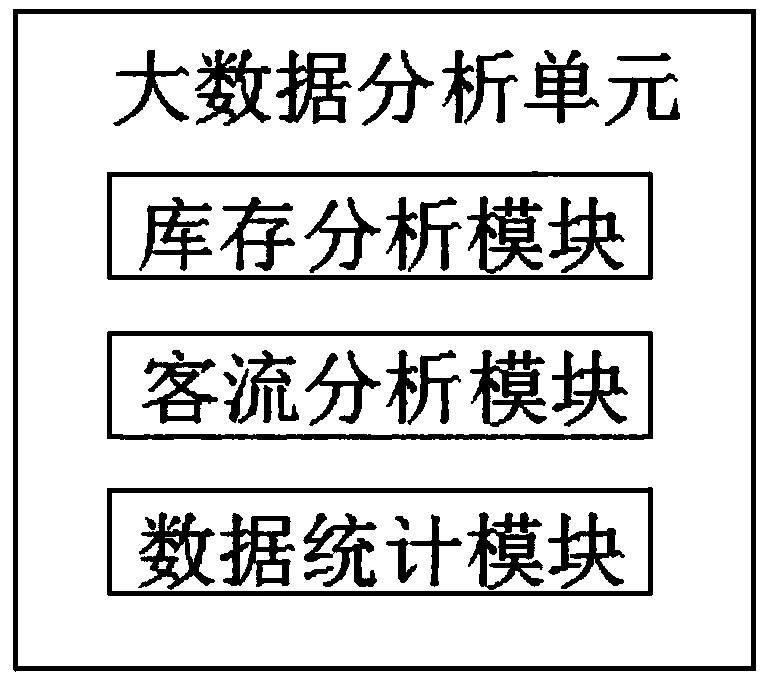

Shopping guiding automatic acquisition analysis system based on big data

InactiveCN108288142AGuaranteed reliabilitySatisfy the use effectLogisticsMarket data gatheringData informationInvoice

The invention discloses a shopping guiding automatic acquisition analysis system based on big data, wherein the system relates to the technical field of a shopping system. The system comprises a central processor and a big data acquisition unit. The big data acquisition unit performs information acquisition on shopping area visitor flowrate, warehouse entering and delivering-out data and selling-out data. The big data acquisition unit is in real-time connection with the central processor through a data information transmission module. According to the system of the invention, corresponding distribution of a plurality of visitor flowrate counters and cameras is utilized for detecting mobility and distribution of customers in a shopping area through a visitor flowrate detecting module. A warehouse management module records the number change of warehousing objects through a warehouse entering registering device and a delivering-out registering device. An invoice management module utilizesa cashier device, a selling-out barcode scanning device and an invoice recording device. The system settles problems of low reliability and excessive manpower and material resource wastage caused bydetermining according to experience and report data.

Owner:安徽千云度信息技术有限公司

Intelligent monitoring system and method for ship with tail gas exceeding standard

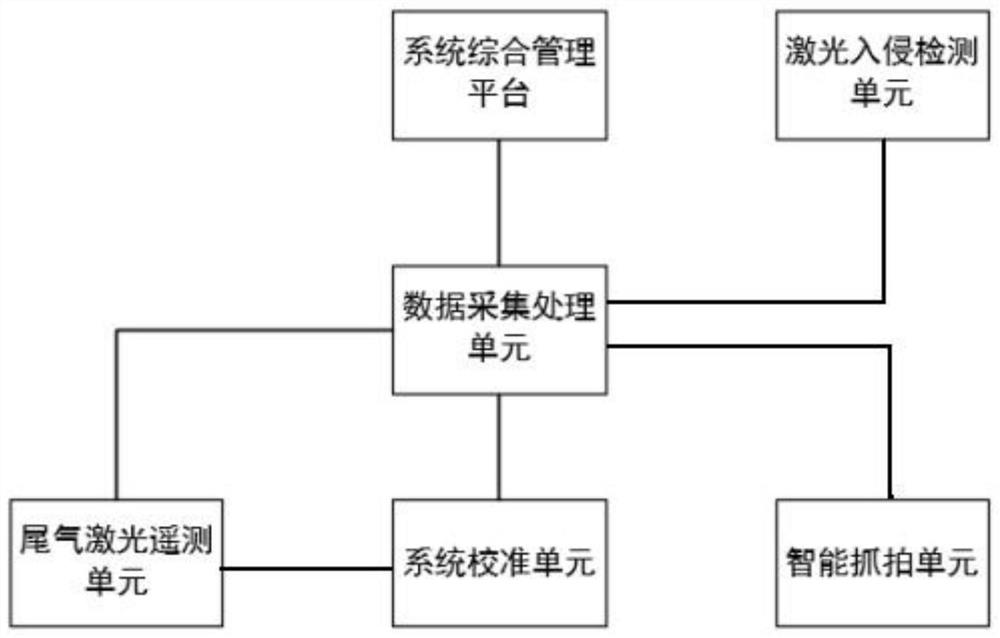

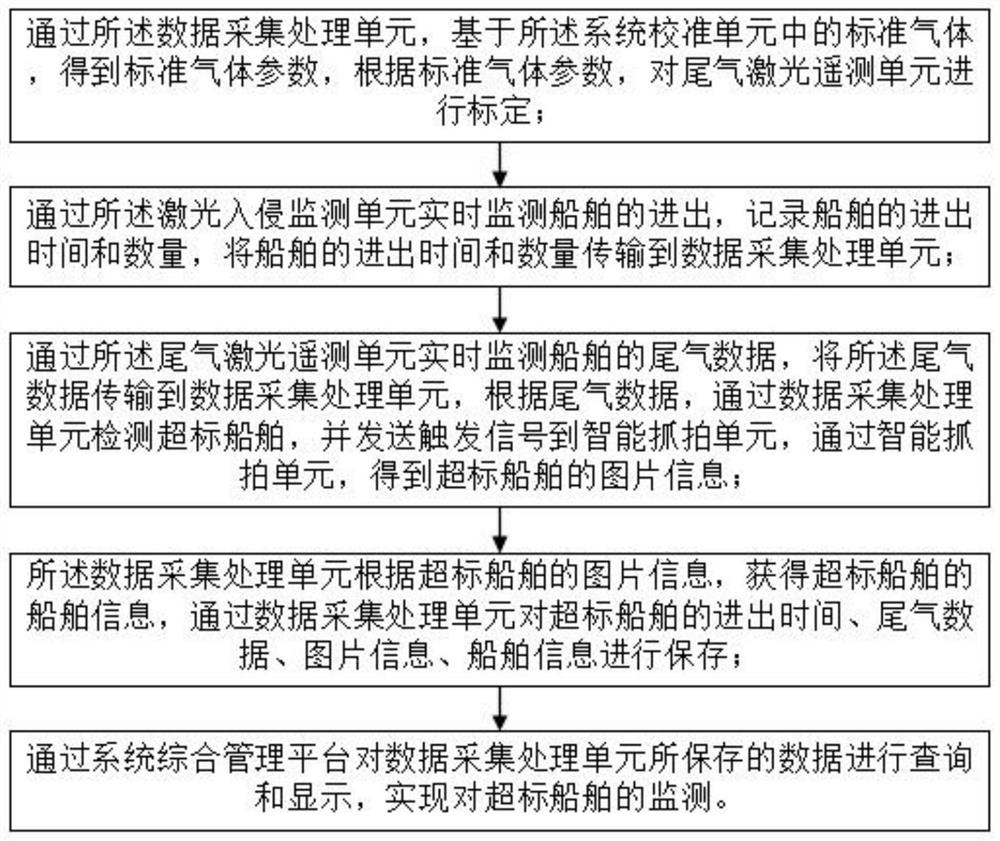

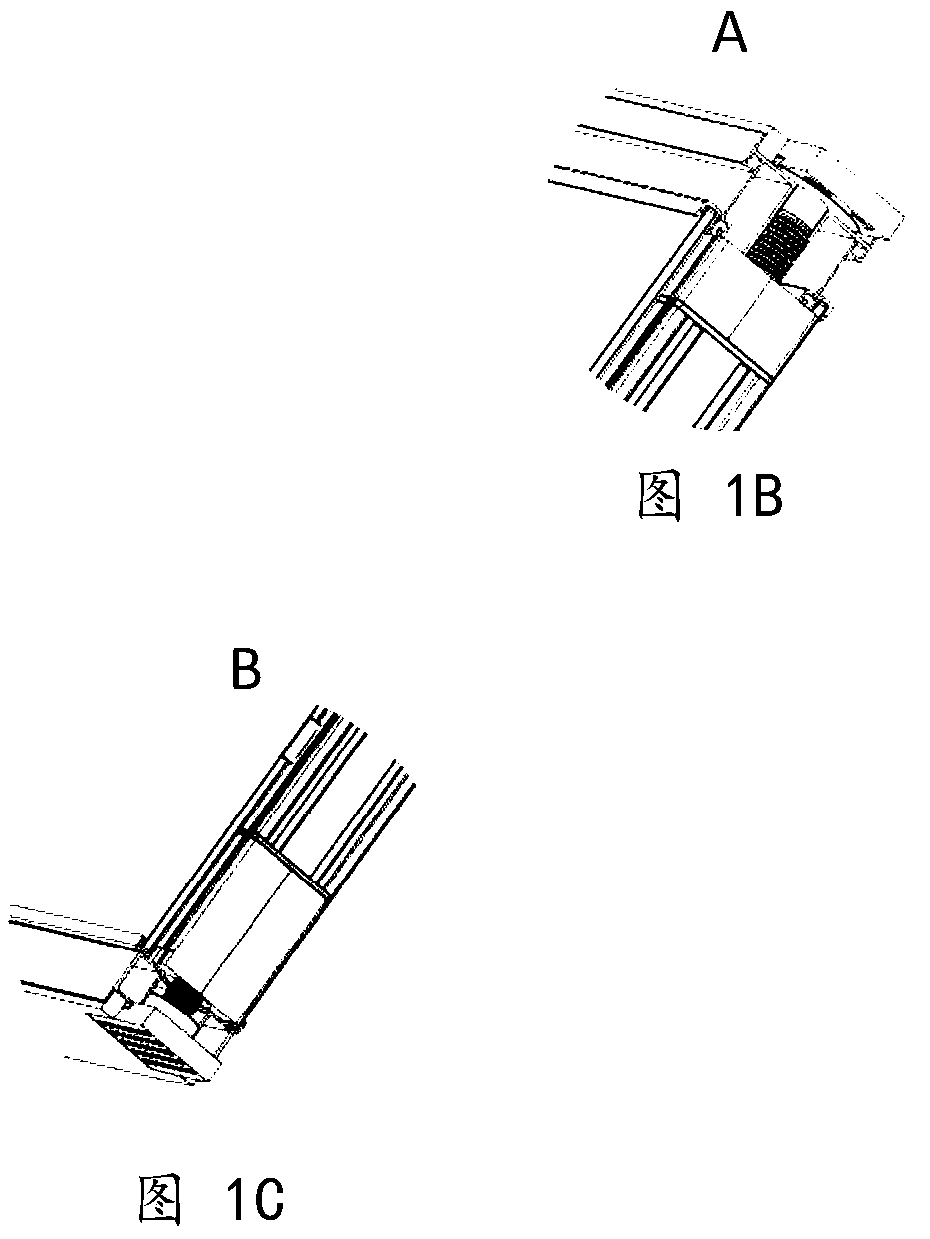

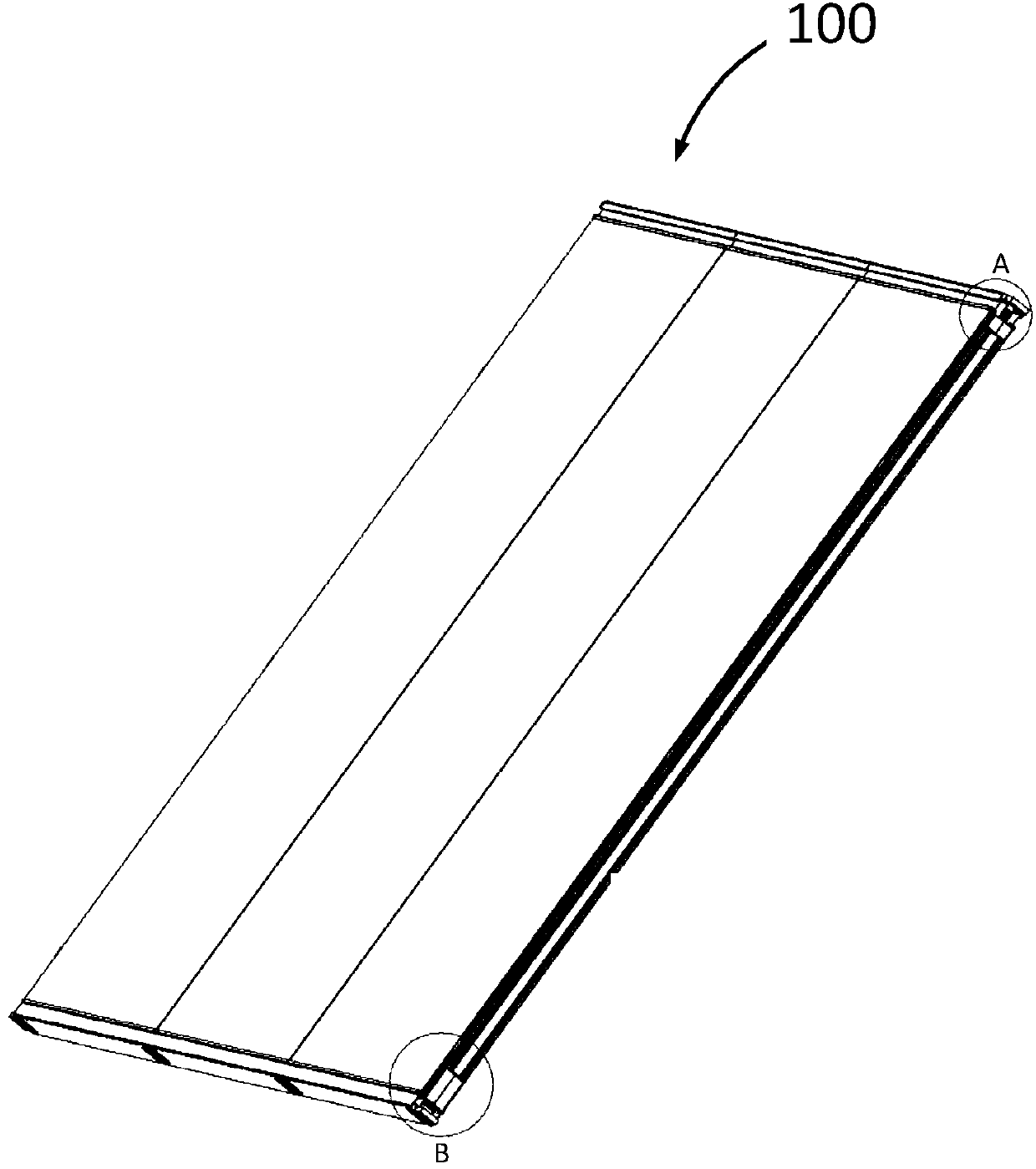

ActiveCN113049037AAvoid acquisition analysisImprove accuracyTelevision system detailsMeasurement devicesCollection analysisMetadata

The invention discloses an intelligent monitoring system and method for a ship with tail gas exceeding the standard. The intelligent monitoring system comprises a tail gas laser telemetering unit, a laser intrusion monitoring unit, an intelligent snapshot unit, a data collecting and processing unit, a system calibration unit and a system comprehensive management platform. The tail gas laser telemetering unit, the laser intrusion unit, the intelligent snapshot unit, the system calibration unit and the system comprehensive management platform are connected with the data acquisition and processing unit. According to the invention, direct collection and analysis of an oil sample are avoided, non-contact measurement is realized, detection blindness is reduced, accuracy of a detection target is improved, ship data collection is carried out on a ship exceeding the standard in a full-automatic manner, and a lot of manpower and material resources are reduced. And meanwhile, the collected standard-exceeding ship data provides an effective data basis for accurate sampling inspection of the maritime affair bureau.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

Inner tension wall

The invention relates to an inner tension wall which comprises a wall body and multiple tension parts located in the wall body. The multiple tension parts can be configured so as to abut against the position between environment objects. The inner tension wall is simple in structure and capable of being rapidly demounted and mounted, and therefore the decoration time can be greatly reduced, the decoration cost is saved, and use of labor and material resources is reduced.

Owner:深圳全景空间工业有限公司

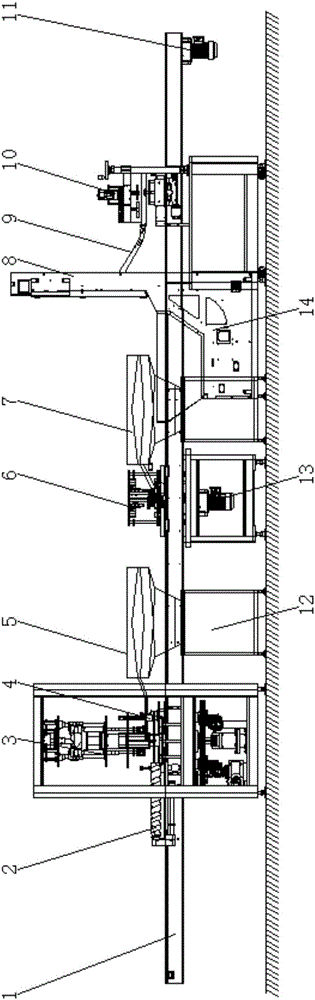

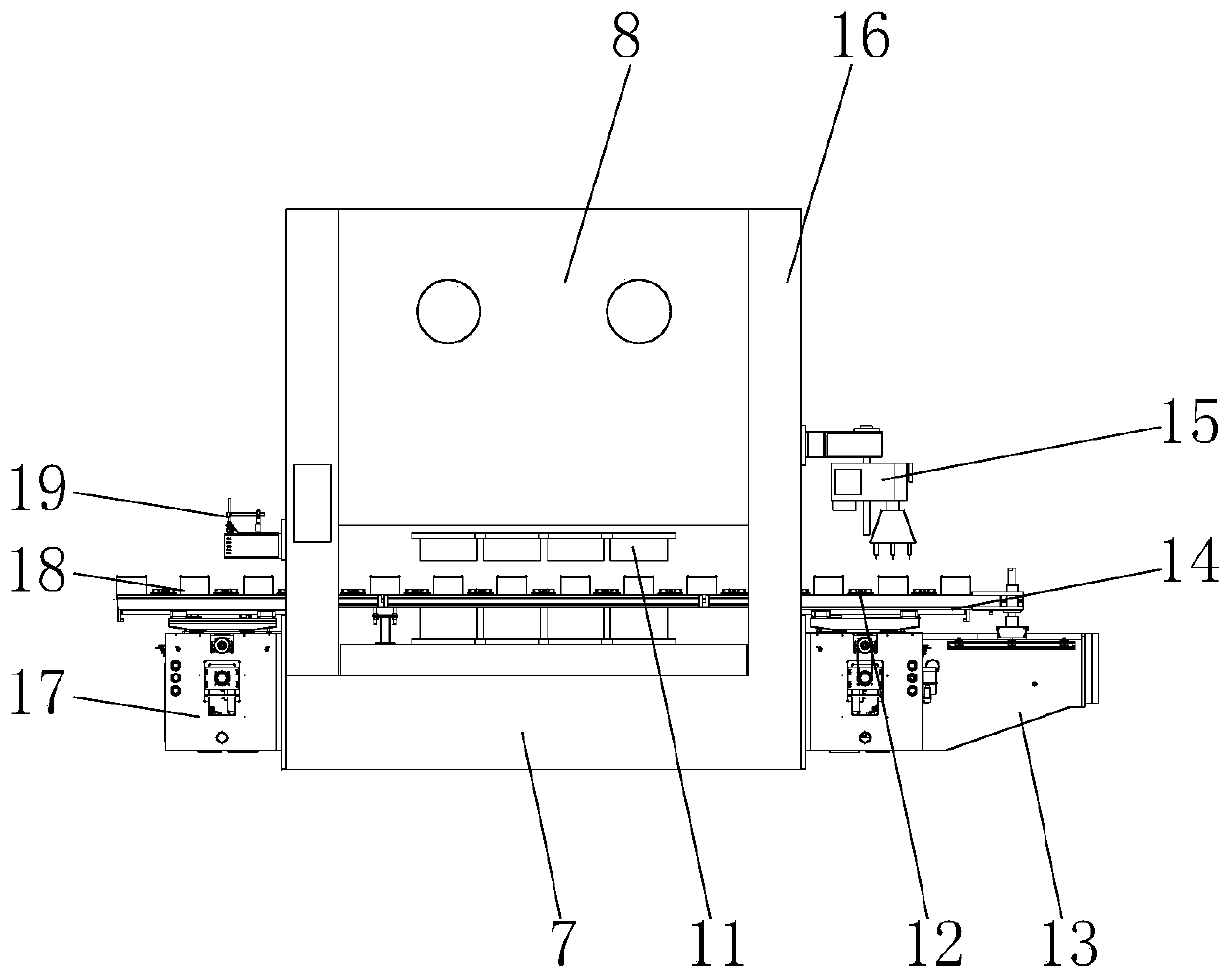

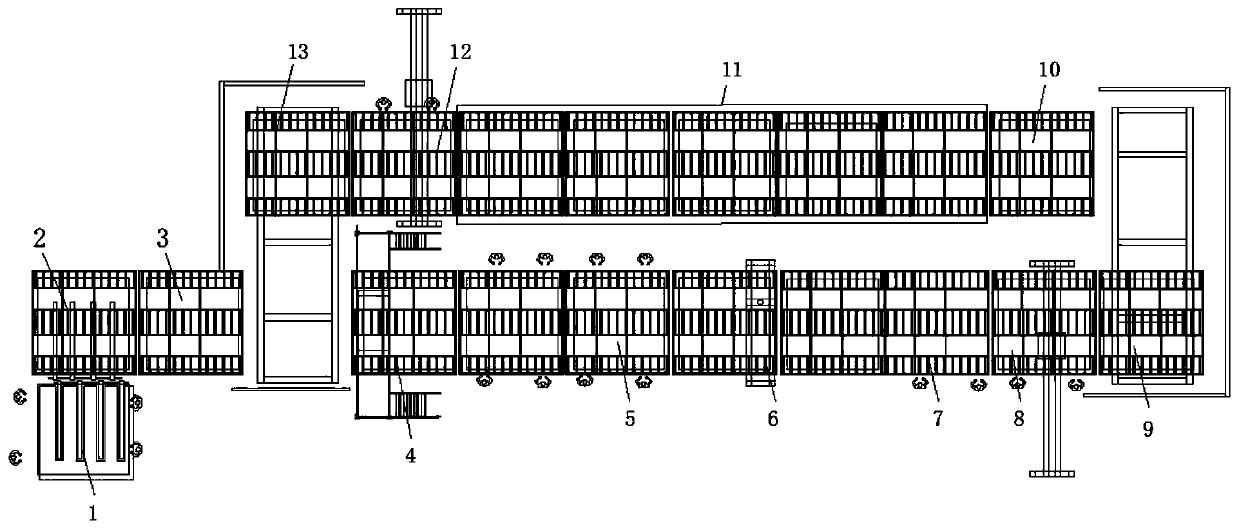

Electric pressure cooker automatic stamping production line

ActiveCN109732364AReasonable distributionNo accumulationOther manufacturing equipments/toolsHollow articlesProduction linePunch press

The invention discloses an electric pressure cooker automatic stamping production line. The production line comprises a slicing machine, two oil hydraulic machines, two free-standing mechanical arms,a conveyor belt, a three-dimensional mechanical arm and a palletizing robot, wherein an oil wiper is arranged on one end of the slicing machine; the other end of the oil wiper is connected with the two oil hydraulic machines; the slicing machine, the oil wiper and the oil hydraulic machines are on the same horizontal direction; a two-arm free standing mechanical arm is arranged between the two oilhydraulic machines; and one of the oil hydraulic machines is externally connected with the conveyor belt through the corresponding free-standing mechanical arm. According to the production line, theslicing machine, the oil wiper, the oil hydraulic machines, the two-arm free-standing mechanical arm, the free-standing mechanical arms, the conveyor belt, the three-dimensional mechanical arm, a punching machine, a servo positioning conveyor belt and the palletizing robot are arranged, so that the problems that manpower and material resources are wasted when a stamping production line is in working, efficiency is low and equipment is not environmentally friendly enough are solved.

Owner:佛山市佛沃机器人科技有限公司

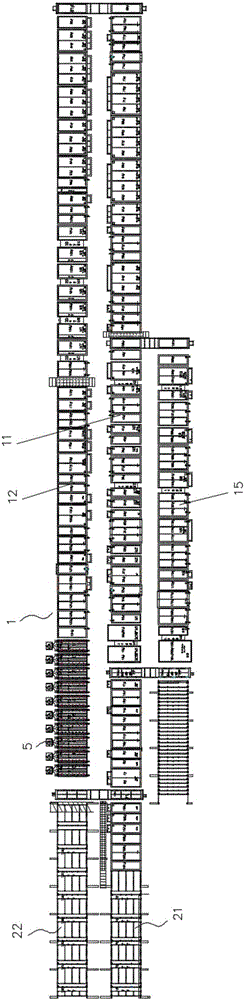

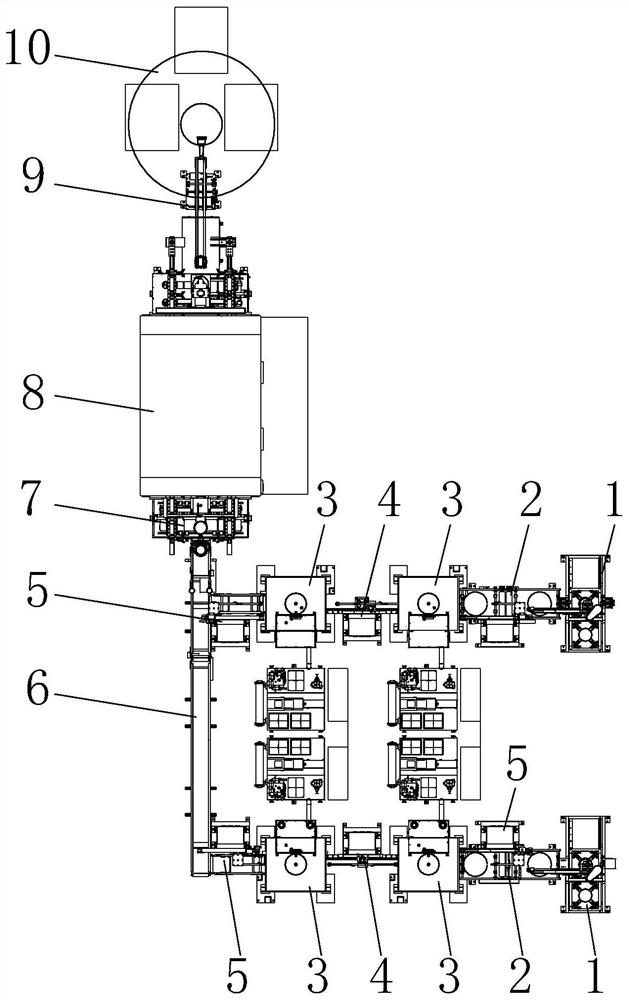

Fully-automatic high rail type ABS automobile part production line

ActiveCN105905556ASingle functionBig errorControl devices for conveyorsMetallic material coating processesProduction lineHuman–machine interface

The invention discloses a fully-automatic high rail type ABS automobile part production line which comprises a production line of a U-shaped structure, wherein a loading device, a transfer device and an unloading device are arranged on the production line; the production line comprises a rack; a transverse moving rail is arranged in the rack; a plurality of mechanical suspension arm lifting vehicles are arranged on the transverse moving rail in the rack; and a plurality of stations are further arranged in the rack. The fully-automatic high rail type ABS automobile part production line implements a functional unit assembly, so that one step is needed for obtaining a product from raw materials, and use of manpower and material resources is reduced. According to the fully-automatic high rail type ABS automobile part production line, the unit fit is optimized, the degree of automation is high, the occupied factory space is small, the pollution source is less, the power consumption is low, the cost is low and the maintenance is easy; the unit adopts transmission of a servo motor for precisely controlling and reducing starting-up and position-covering time, so that the product waste length is shortened; and communication of a human-computer interface is operated by one person, so that unit fit can be completed.

Owner:广州市中亚装饰设计工程有限公司

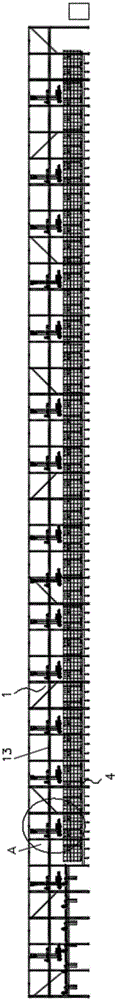

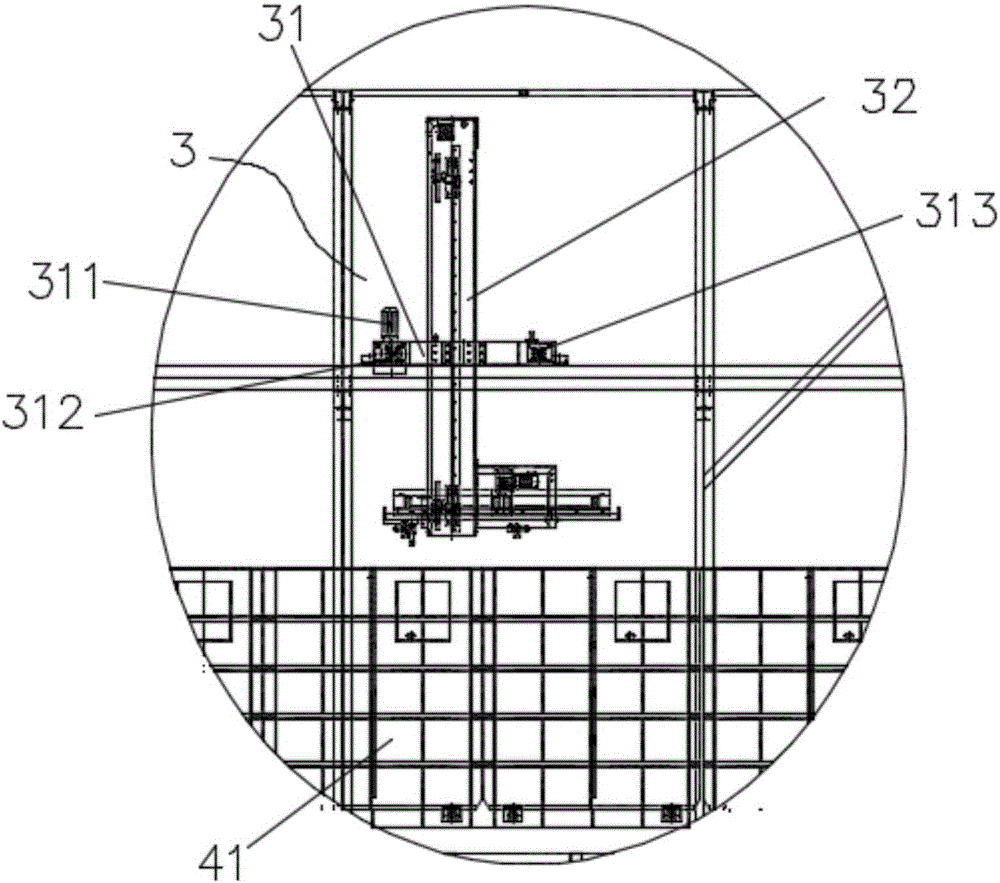

Automatic wall production line

InactiveCN110774438AReduce the use of manpower and material resourcesHigh degree of automationCeramic shaping plantsFlat articlesProcess engineeringWall plate

The invention relates to the technical field of wall production, in particular to an automatic wall production line. The automatic wall production line comprises a keel assembling station, a plate overturning and conveying station, a keel waiting station, a keel tool feeding station, a line and pipe placing station, a grouting station, a calcium carbonate plate installation station, a foamed wallplate offline station, a product transferring station, a product ascending curing box station, a three-layer curing conveying tunnel furnace, a product offline station and a tool plate return and transferring station. The keel assembling station and the plate overturning and conveying station are connected through a plate overturning plate and a roller conveying line. The automatic wall productionline achieves the purpose that the capability of automatically producing two kinds of wall plates is achieved, the operation from raw materials to products is conducted in one step, use of labor andmaterial resources is reduced, the automation degree is high, the plant occupying space is small, pollution sources are few, power consumption is small, the cost is low, and maintenance is easy; and most of labor force can be liberated to a great degree, the manual participation amount in the production process is reduced, and in addition, the production efficiency is high.

Owner:中山新硕智能科技有限公司

Insulator placing frame with cleaning function

ActiveCN108216858AReduce the use of manpower and material resourcesAvoid harmCleaning using liquidsInternal fittingsEngineeringWater resources

The invention discloses an insulator placing frame with cleaning function, which comprises a supporting plate; the top part of the supporting plate is provided with a slide pillar, one side of the slide pillar is provided with a connecting pillar, and the bottom end of the connecting pillar is provided with a pulley; the bottom end of the slide pillar is provided with a limiting device, the top part of the supporting plate is provided with a placing block. The invention relates to the technical field of the insulator. Through arranging the limiting device, the chute, the fixing device, a buckle slot and a limiting slot, the insulator placing frame with cleaning function can be cleaned without moving the insulator, thus the use of labor force and materials can be saved, the harm to the insulator is avoided; through a collecting device, a water pump, a hose, a connecting pipe, a diversion pipe, a guide flow box, a water permeating hole and a guide flow plate, the excessive waste of the water resource is avoided, the cleaning cost is reduced, and the cleaning efficiency is indirectly improved.

Owner:浙江万工电气有限公司

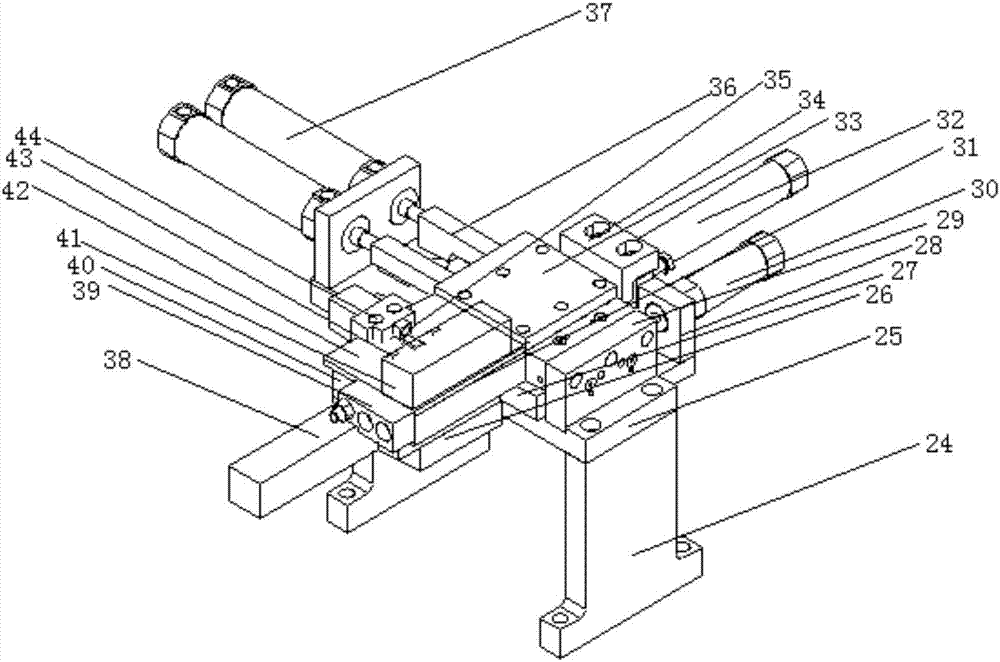

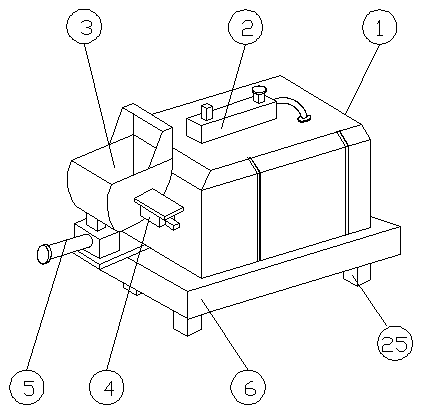

Full-automatic tapping device

InactiveCN107262849AImprove processing efficiencyReduce the use of manpower and material resourcesThread cutting feeding devicesMaterial supplyMaterial resources

The invention relates to the technical field of machining, in particular to a full-automatic tapping device which is provided with a horizontal type processing shaft and a vertical type processing shaft. By adopting the full-automatic tapping device, through automatic material supply of a vibration disc, a supplied material passes through a jig assembly body and is processed by a control panel. The full-automatic tapping device performs full-automatic feeding processing, so that the processing efficiency is improved, and uses of manpower and material resources are saved.

Owner:ZHEJIANG TONGTAI BEARING

Textile washing equipment

InactiveCN108330634AImprove washing effectImprove washing efficiencyMechanical cleaningSucessive textile treatmentsEngineeringMechanical engineering

The invention discloses textile washing equipment which comprises a machine body and bases, wherein the bases are arranged in a left and right symmetry manner at the bottom of the machine body; pressing conveying components are symmetrically arranged on the left end surface and the right end surface of the machine body; the pressing conveying components comprise opened cavities which are opened outwards; two conveying rollers which are arranged in the left and right symmetry manner are rotationally arranged at the lower parts of the opened cavities through first rotating shafts; lifting chutesare arranged in end walls of the inner sides at the upper parts of the opened cavities. By adopting the textile washing equipment, integral operations of clamping, tightening, conveying, washing anddrying of a textile fabric can be achieved, an automatic washing operation of the textile fabric can be achieved, the washing effect and the washing efficiency of the textile fabric can be greatly improved, a good washing effect can be achieved, the textile fabric can be prevented from wrinkling in the washing process, the textile washing equipment is simple in structure, convenient and rapid to operate and low in production cost, the labor and materials can be greatly saved, steps of textile fabric washing can be simplified, and the textile fabric washing time can be shortened.

Owner:陈李月

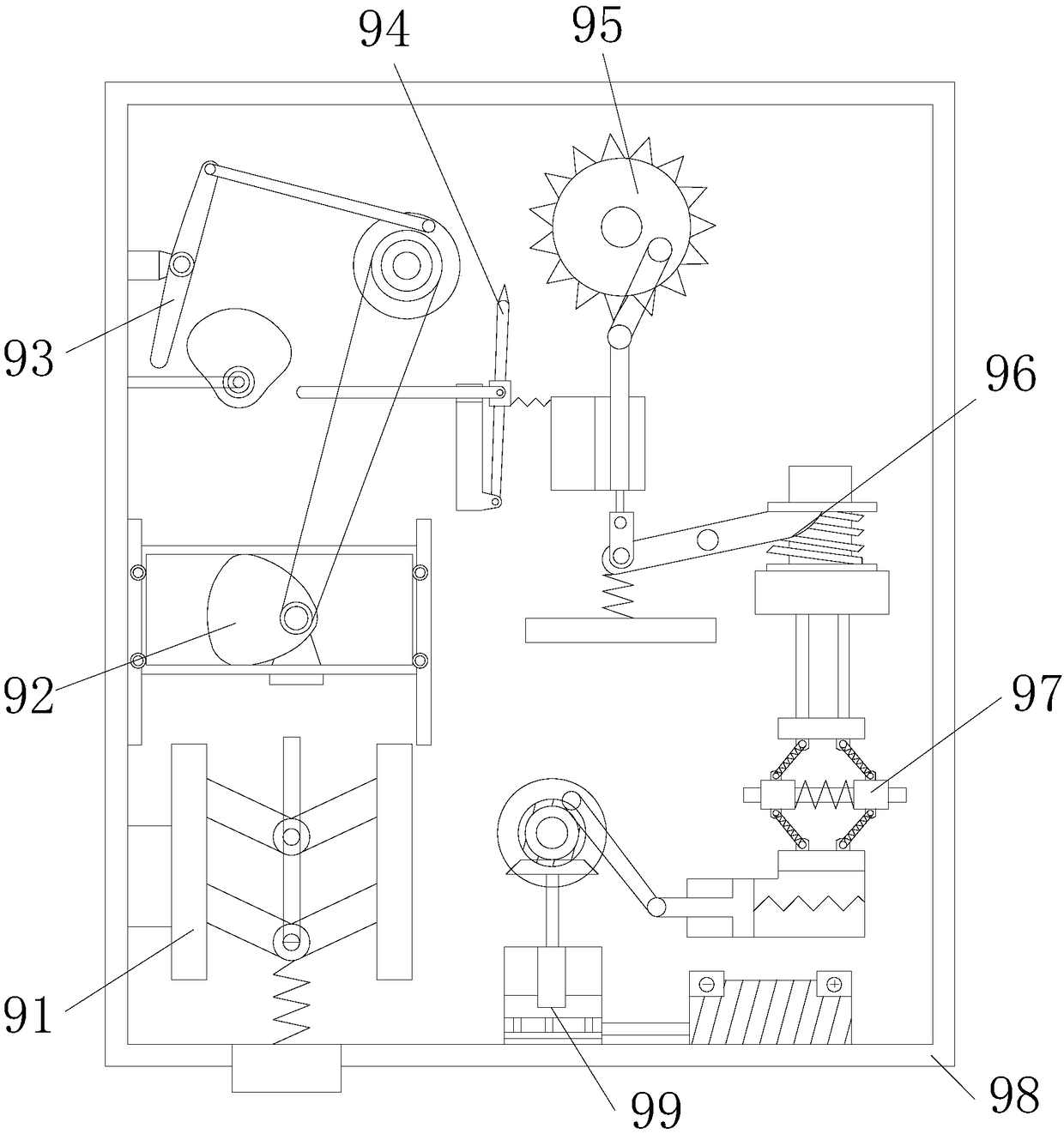

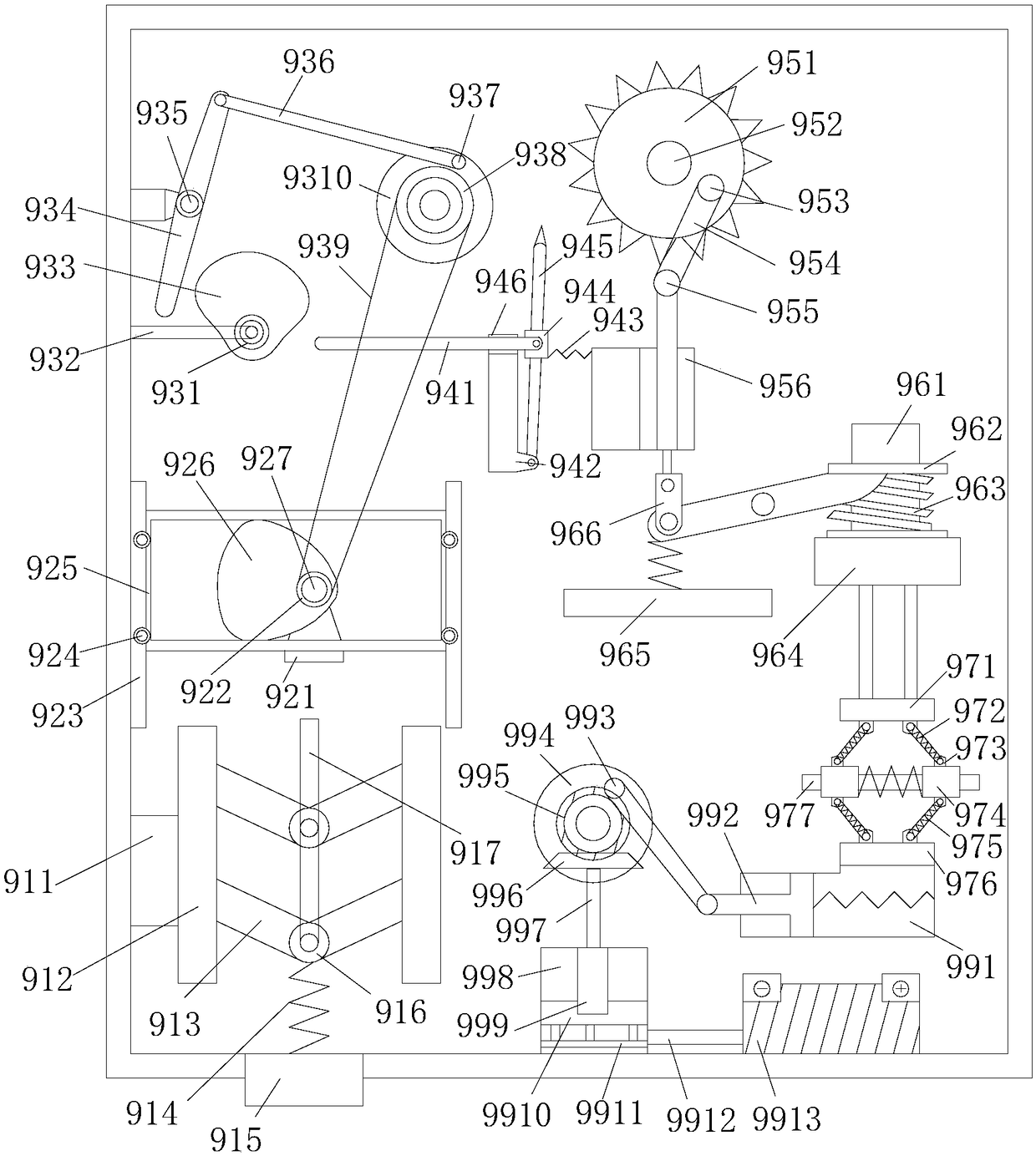

Convenient-to-move concrete pump

InactiveCN109184214AReduce the use of manpower and material resourcesEasy to moveBuilding material handlingGear driveGear wheel

The invention discloses a convenient-to-move concrete pump, which comprises a shell. A movable device is symmetrically arranged in the base; the moving device comprises a first transmission rod; one end of the first transmission rod is connected with a second gear; the first transmission rod is located on the base and is provided with a first bearing; one end of the first transmission rod is provided with a third gear; one side of the third gear is engaged with a fourth gear; and a connecting rod is arranged between second transmission rods. The first gear is driven by a driving motor, the first gear drives a second gear, the second gear drives the first transmission rod, the third gear drives a fourth gear to rotate, a first rotating rod on the fourth gear rotates, a lifting sleeve outside the first rotating rod lifts, the second transmission rod thus lifts, a vertical rod on the second transmission rod lifts, and a roller thus lifts. The convenient-to-move concrete pump has the beneficial effects that the roller is put down in the case of moving, the roller is taken up in the case of construction, a support leg is used for support, and the use of manpower and material resources in the process of handling is reduced.

Owner:ANHUI MINGGUANG RUISHENG MACHINERY

An insulator placement rack with cleaning function

ActiveCN108216858BAvoid harmSave manpower and material resourcesCleaning using liquidsInternal fittingsWater resourcesEngineering

The invention discloses an insulator placing frame with cleaning function, which comprises a supporting plate; the top part of the supporting plate is provided with a slide pillar, one side of the slide pillar is provided with a connecting pillar, and the bottom end of the connecting pillar is provided with a pulley; the bottom end of the slide pillar is provided with a limiting device, the top part of the supporting plate is provided with a placing block. The invention relates to the technical field of the insulator. Through arranging the limiting device, the chute, the fixing device, a buckle slot and a limiting slot, the insulator placing frame with cleaning function can be cleaned without moving the insulator, thus the use of labor force and materials can be saved, the harm to the insulator is avoided; through a collecting device, a water pump, a hose, a connecting pipe, a diversion pipe, a guide flow box, a water permeating hole and a guide flow plate, the excessive waste of the water resource is avoided, the cleaning cost is reduced, and the cleaning efficiency is indirectly improved.

Owner:浙江万工电气有限公司

A photoelectric angle measuring device

The invention discloses a photoelectric type angle measuring device, and relates to the technical field of angle measurement. The photoelectric type angle measuring device comprises a box body and a bottom cover. The bottom of the bottom cover is rotatably connected with an annular base, and a positioning device is fixed to the peripheral side surface of the box body. A lase emitter and a luminometer are separately fixed to one opposite inner wall of the box body, and an optical filter assembly is rotatably connected to the top of the inner wall of the box body through a hinge seat. The optical filter assembly comprises a optical filter, and a fixing ring is fixed to the peripheral side surface of the optical filter. According to the photoelectric type angle measuring device, the box bodyis rotated through the cooperation of a limiting block, a limiting notch, a sliding rod and an annular notch, the angle to be measured again is selected through the relative positions of a scale ringand a scale, the relative positions of the bottom cover and the annular base are limited through the positioning device, angle values of different angles of an object can be quickly and accurately measured, and the problem that the measurement is inaccurate after the measurement angle of an existing angle measuring device is changed is solved.

Owner:李成山

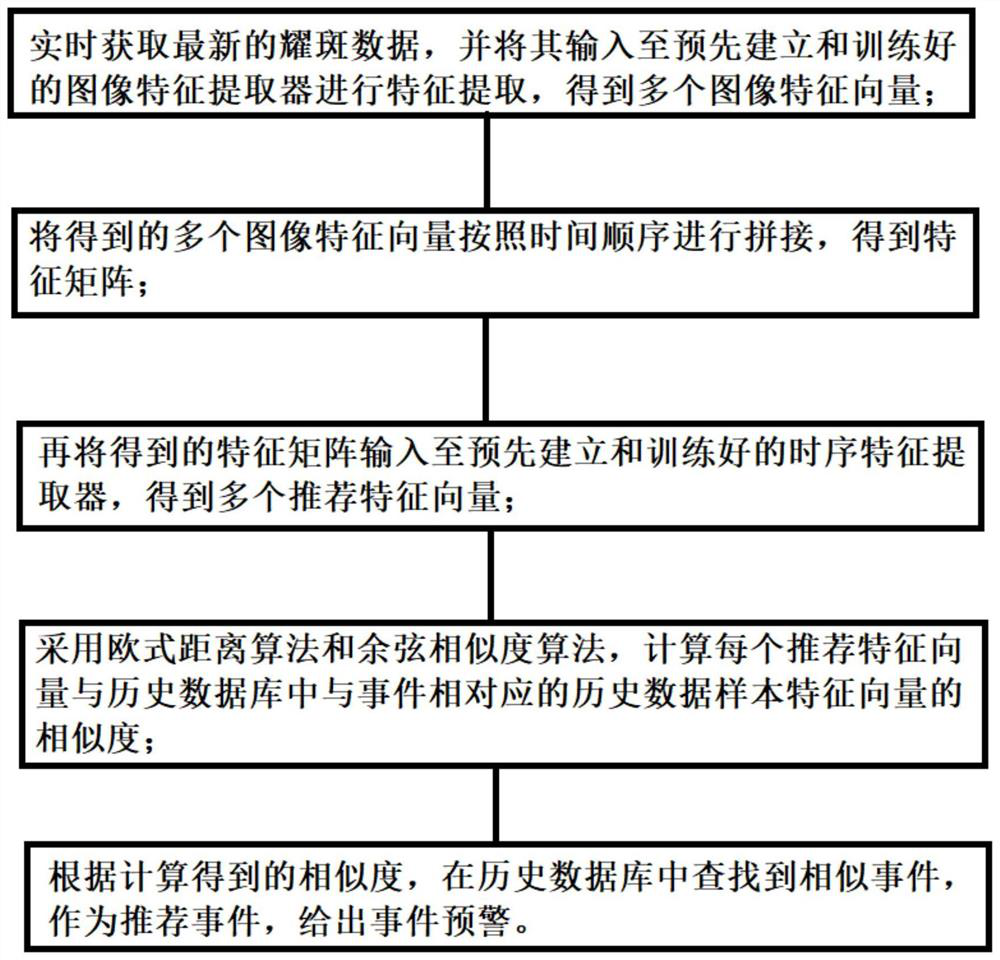

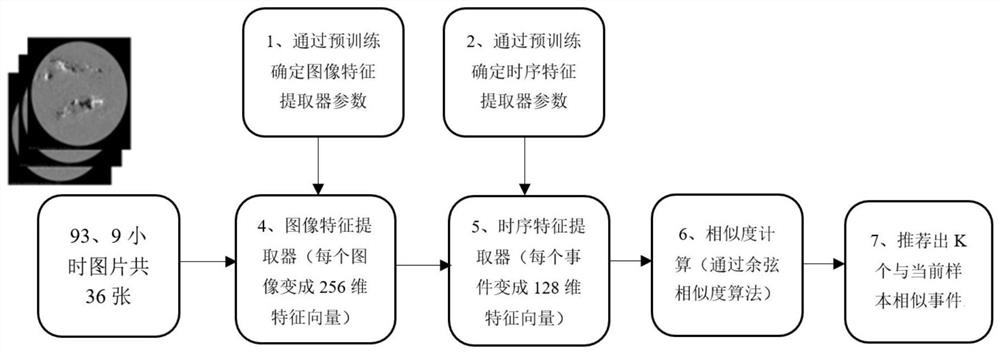

Early warning method and early warning system for solar flares

PendingCN113610762AFeature Extraction ReductionReduce the use of manpower and material resourcesImage enhancementImage analysisEuclidean distanceMultiple image

The invention belongs to the technical field of satellite data monitoring, and particularly relates to an early warning method and early warning system for solar flares, and the method comprises the steps: obtaining the latest flares data in real time, inputting the data into a pre-established and trained image feature extractor for feature extraction, and obtaining a plurality of image feature vectors; splicing the obtained multiple image feature vectors according to a time sequence to obtain a feature matrix; inputting the obtained feature matrix into a pre-established and trained time sequence feature extractor to obtain a plurality of recommended feature vectors; calculating the similarity between each recommendation feature vector and a historical data sample feature vector corresponding to the event in a historical database by adopting an Euclidean distance algorithm and a cosine similarity algorithm; and according to the similarity obtained through calculation, finding similar events in a historical database to be taken as recommended events, and giving event early warning.

Owner:NAT SPACE SCI CENT CAS

An auxiliary shooting scoring system based on wireless sensor technology

InactiveCN104689550BReduce the use of manpower and material resourcesAvoid controversySport apparatusTime rangeLine sensor

The invention discloses an auxiliary shooting scoring system based on wireless sensing technology, which is deployed at both ends of a basketball field, and the system at each end is composed of a processor, a timer, a display, a pressure sensor, a wireless multimedia node and two infrared sensors , using infrared sensors, pressure sensors, and wireless multimedia nodes to collect data, and submit the information to the microprocessor for processing to complete the analysis and processing of the data, so as to complete the scoring function. During the shooting process, the pressure sensor first senses the change of this force, and will submit its own number and the moment of sensing the change of this force to the processor. When the upper and lower infrared sensors installed on the same backboard are within the specified time range If a basketball is detected successively, it will transmit information to the processor, and the processor will perform corresponding scoring processing based on the information submitted by the infrared sensor, the pressure sensor and the wireless multimedia node.

Owner:NANJING UNIV OF POSTS & TELECOMM

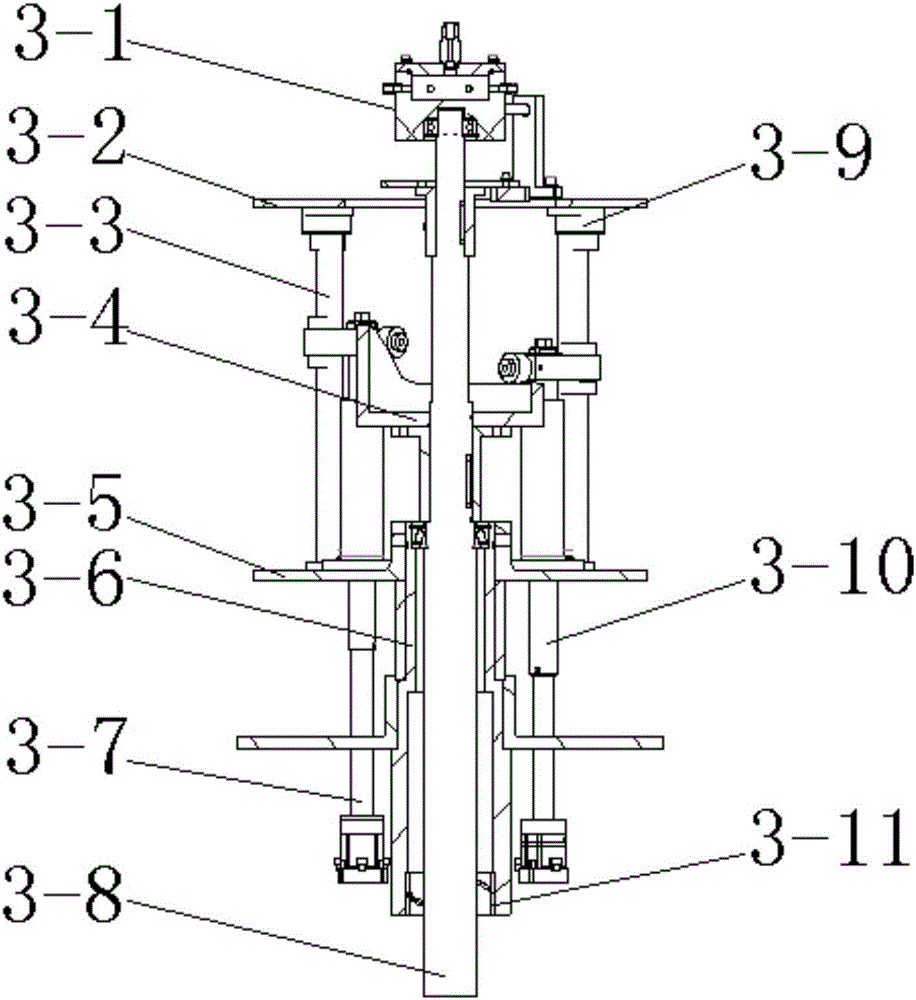

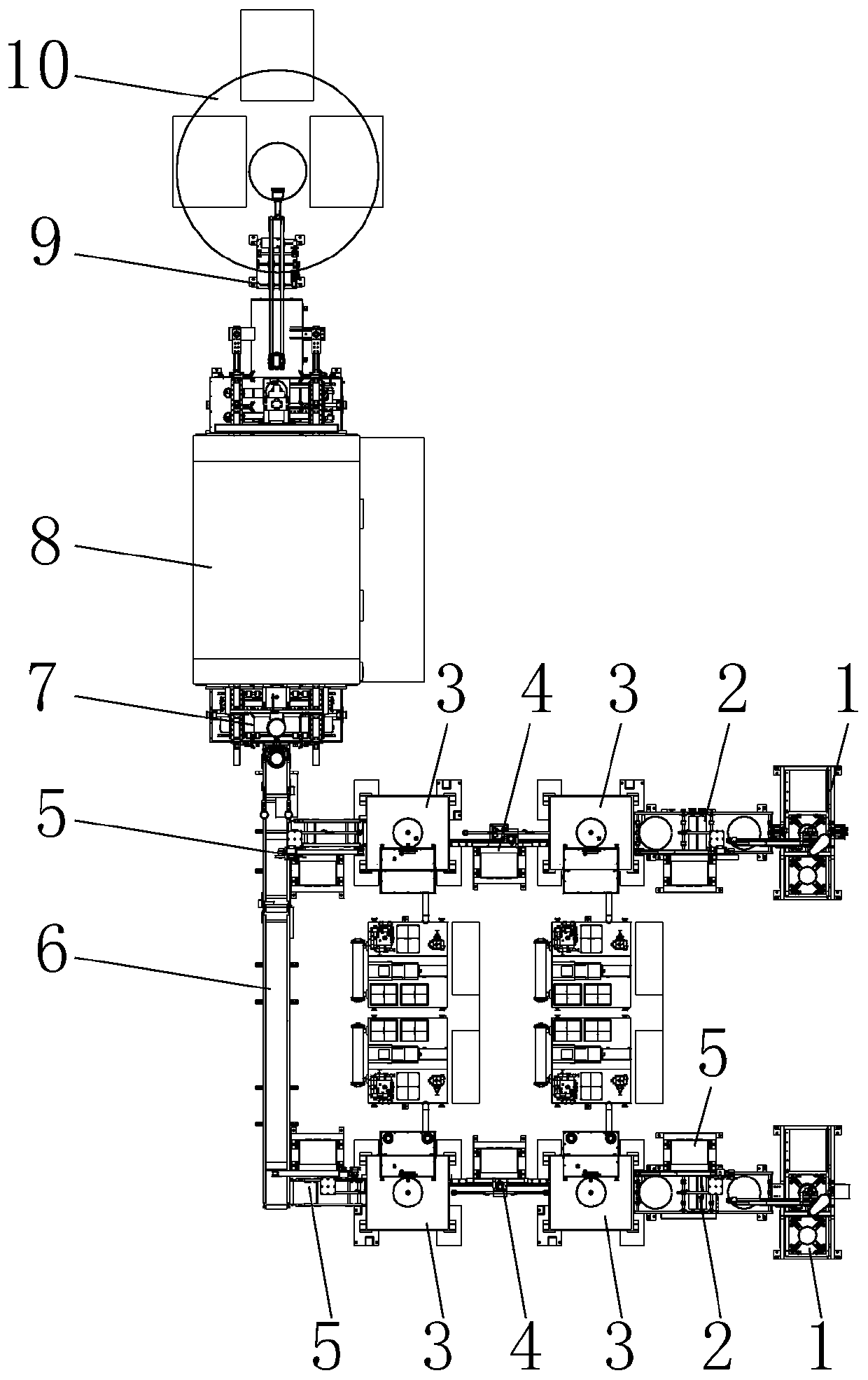

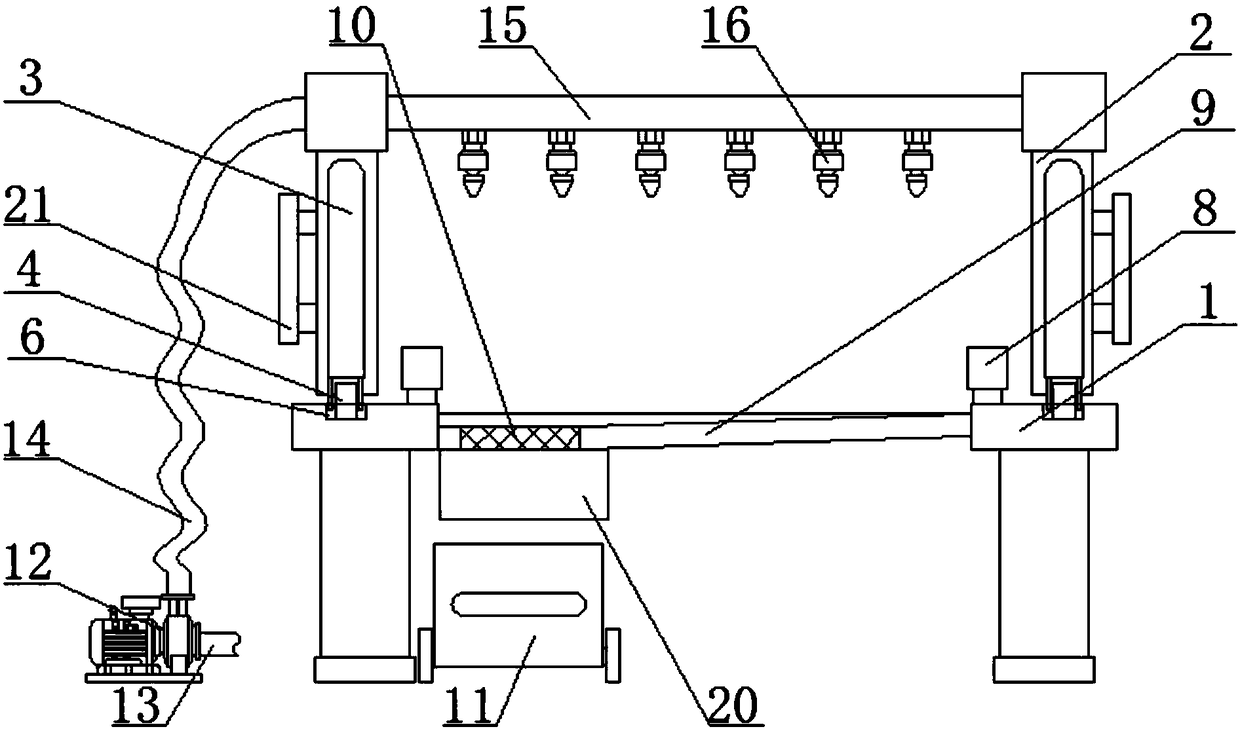

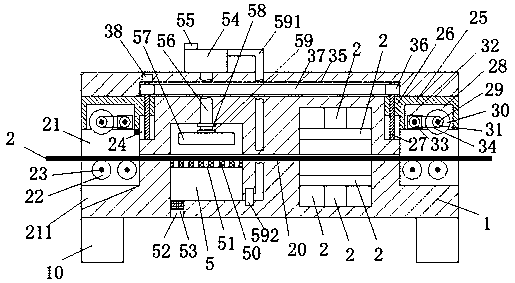

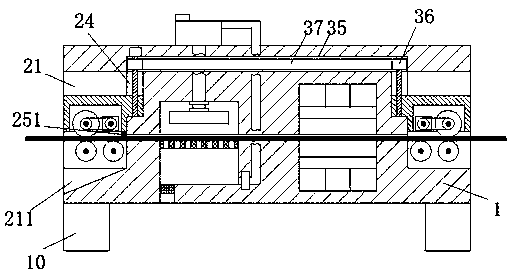

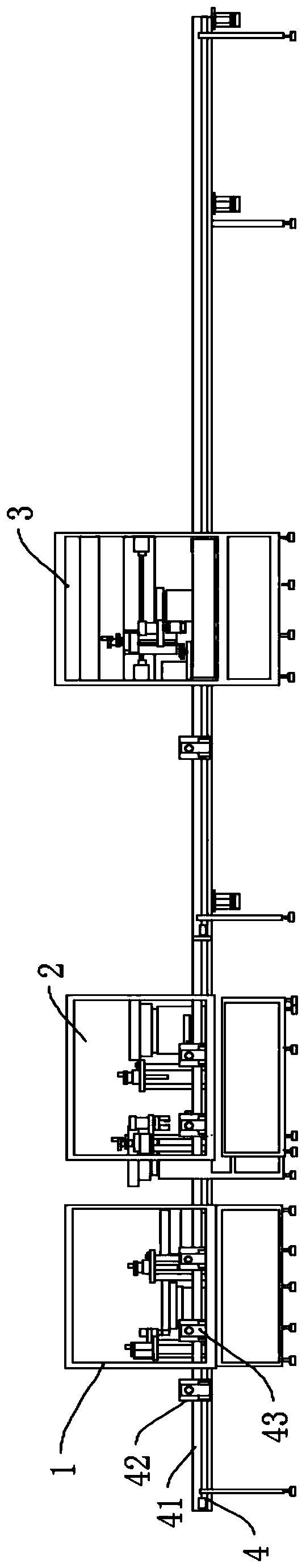

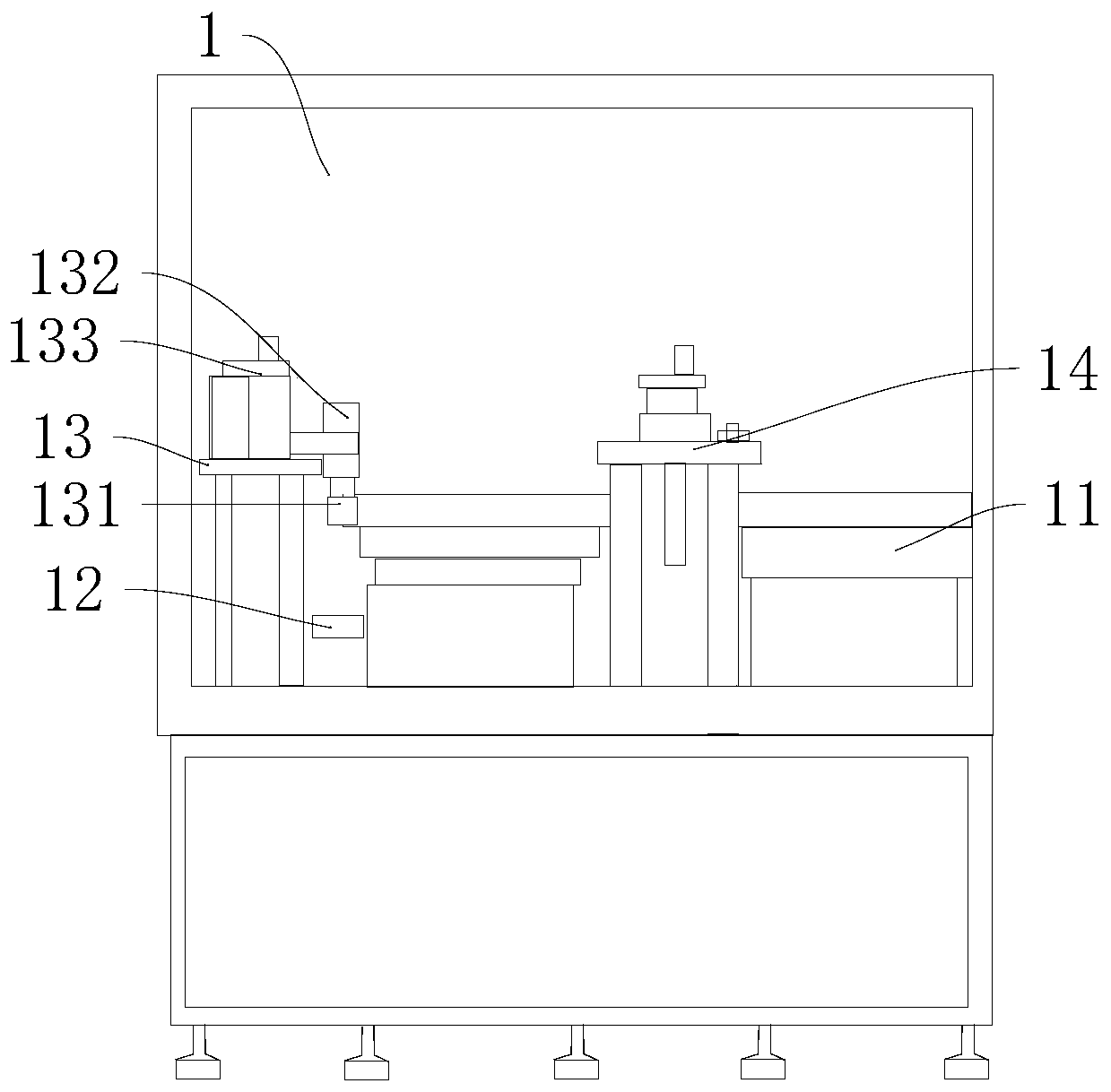

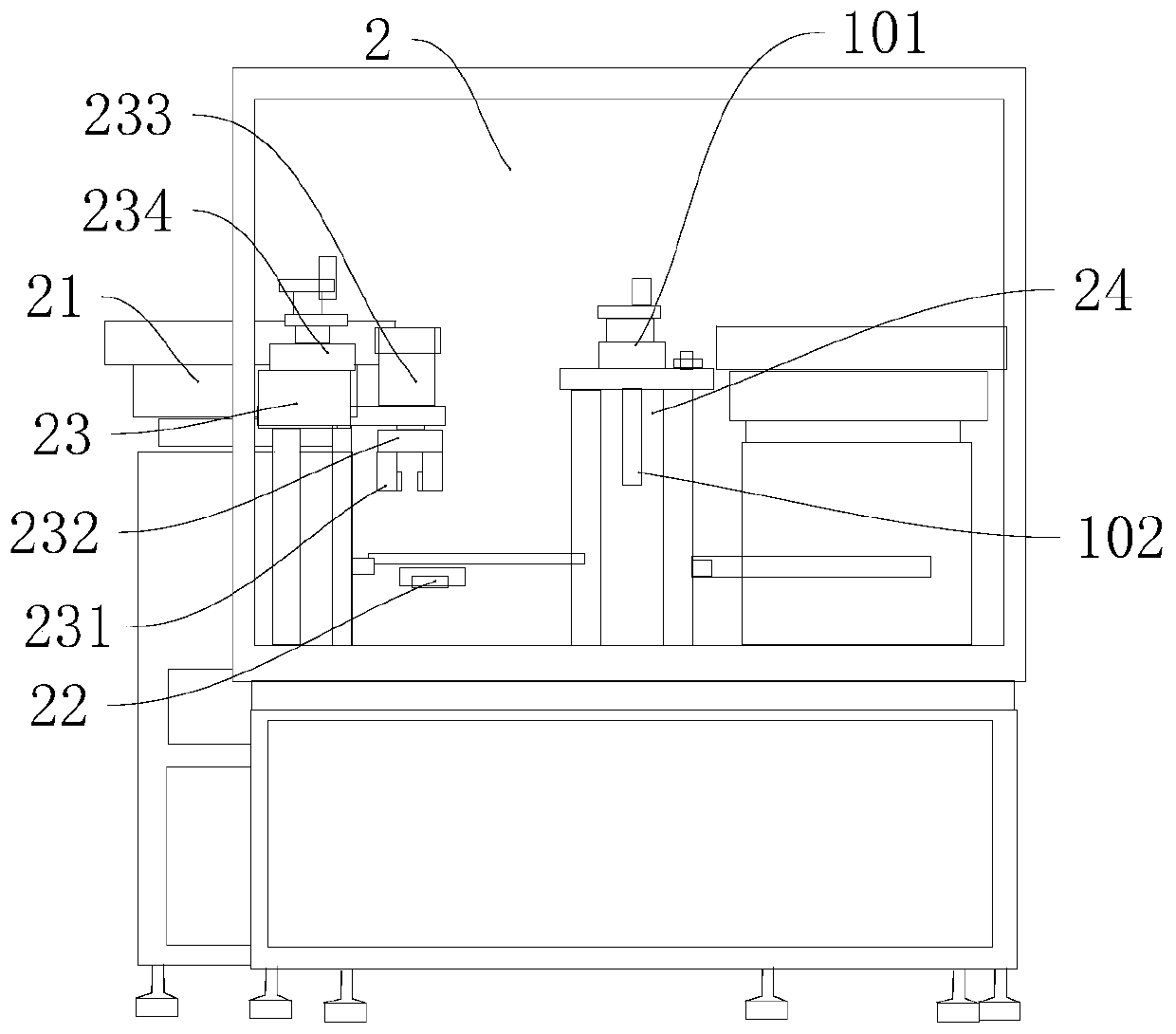

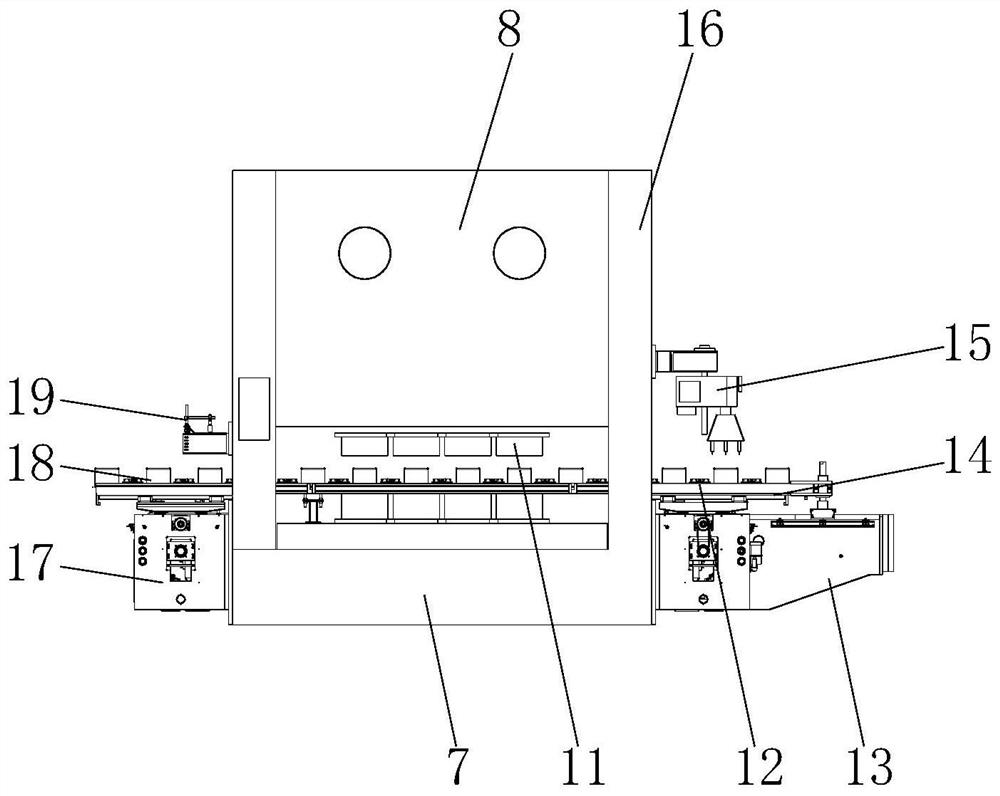

Full-automatic plug pressing, core pressing and cap screwing production line

InactiveCN111392668AReduce the use of manpower and material resourcesOptimal fitThreaded caps applicationConveyorsMaterial resourcesManufacturing line

The invention discloses a full-automatic plug pressing, core pressing and cap screwing production line, which comprises a full-automatic plug pressing machine, a full-automatic core pressing machine,a full-automatic cap screwing machine and a conveying belt, wherein protective belts are arranged on the two sides of the conveying belt; the conveying belt sequentially penetrates through the full-automatic plug pressing machine, the full-automatic core pressing machine and the full-automatic cap screwing machine; and a bottle distribution mechanism and a bottle blocking mechanism are arranged onthe conveying belt. According to the full-automatic plug pressing, core pressing and cap screwing production line, the use of manpower and material resources is reduced, the cooperation between unitsis optimized, the automation degree is high, the operation is easy, the working efficiency is high, the normal operation of a filling, plug pressing, core pressing and cap screwing interlocking machine is facilitated, the automatic mechanized production of the whole process is achieved the labor intensity and the labor cost are greatly reduced, the plug pressing, core pressing and cap screwing are accurate, and production control is facilitated.

Owner:ZHUHAI HERMESIN ENTERPRISES CO LTD

A non-ferrous metal processing device

ActiveCN108436669BGrinding is safe and stablePrevent rotationGrinding drivesGrinding machinesMaterial resourcesEngineering

The invention discloses a non-ferrous metal treatment device. The non-ferrous metal treatment device comprises a pedestal and a conveying table; the conveying table is removably arranged at the bottomof the right end surface of the pedestal; standing bars are fixedly arranged at the four corners of the bottom of the pedestal and the bottom of the conveying table; sucking disks used for sucking the whole device on the ground are fixedly arranged at the bottoms of the standing bars; an accommodating cavity is formed in the right end surface of the pedestal; a cavity body is formed in the part,located at the left end of the accommodating cavity, in the pedestal; an upper driving and moving groove is formed in the top end wall of the cavity body; a first conversion cavity elongating up and down is formed in the part, located at the left end of the cavity body, in the pedestal; a second conversion cavity is formed in the part, located below the cavity body, in the pedestal; and a lower driving and moving groove is formed in the bottom end wall of the second conversion cavity. The non-ferrous metal treatment device is simple in structure and convenient and rapid to operate, the use ofmanpower and material resources is reduced, and the safety of equipment is improved.

Owner:烟台吉森新材料科技有限公司

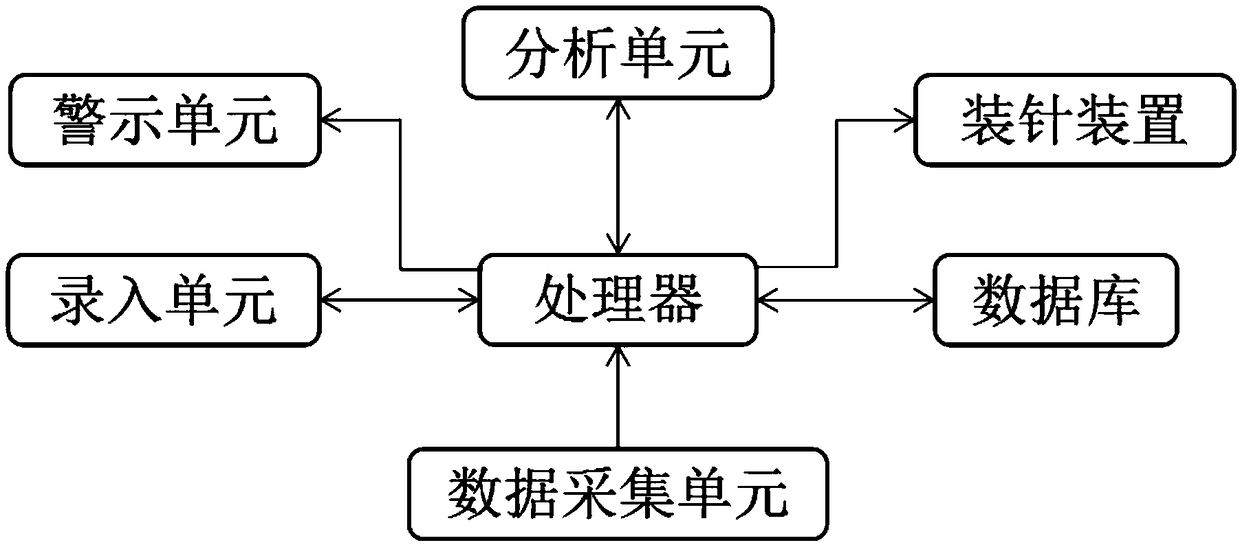

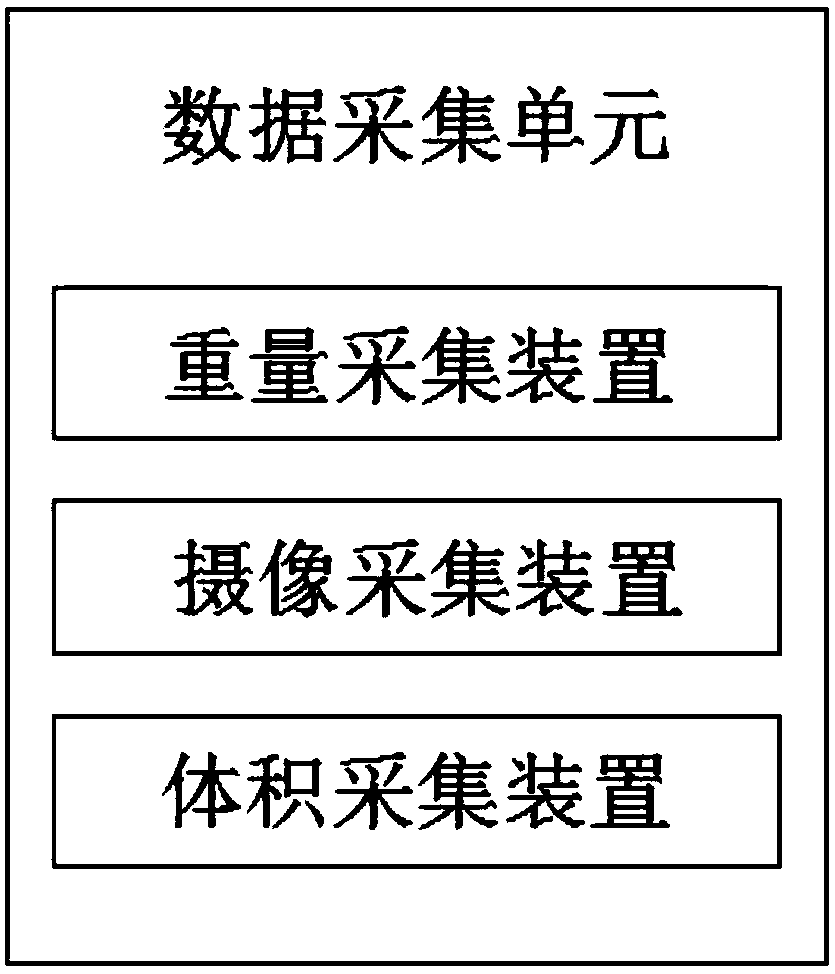

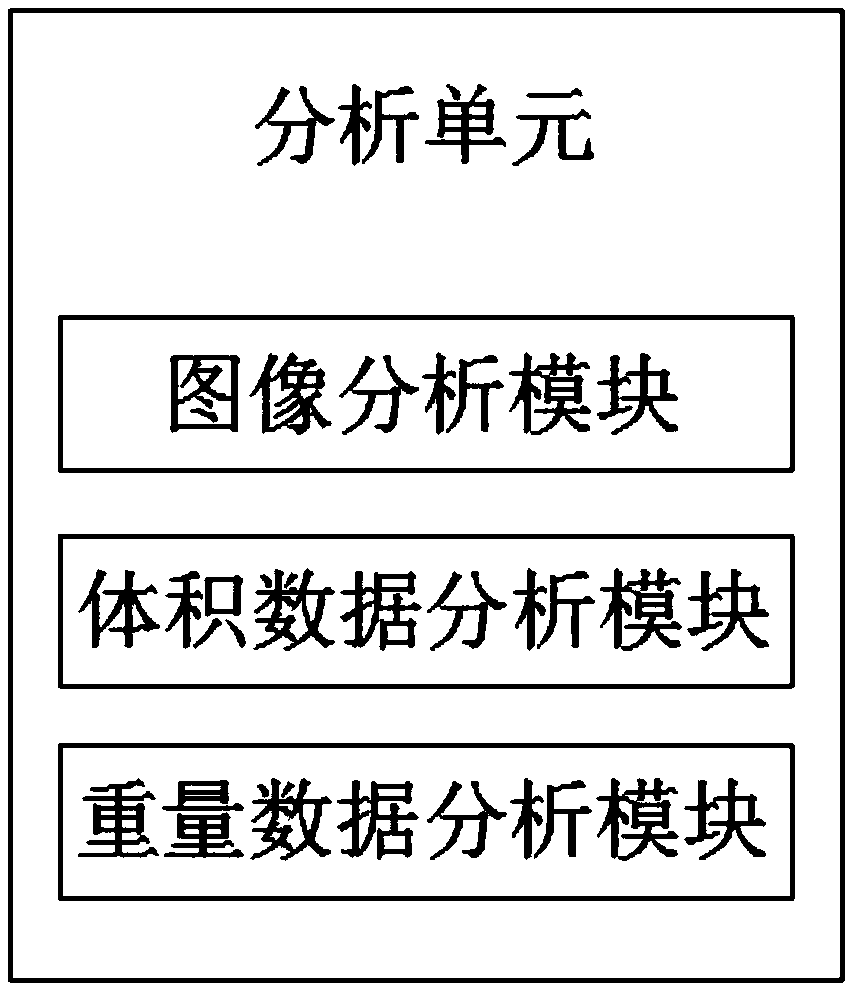

Automatic pointer identification system

InactiveCN108764101AEasy to identifyReduce the use of manpower and material resourcesCharacter and pattern recognitionDashboardVolumetric data

The invention discloses an automatic pointer identification system and relates to the technical field of dashboard assembly. The automatic pointer identification system comprises a processor, a database, a data acquisition unit, an analysis unit, an input unit, a pointer installing device and a warning unit. The processor is an ARM9-series processor. The data acquisition unit comprises a weight acquisition device, a camera acquisition device and a volume acquisition device, and accurately identifies a pointer by acquiring the weight, the volume and the image data of the pointer. The automaticpointer identification system acquires the weight data of the pointer by the weight acquisition device, acquires the image data of the pointer by the image acquisition device, acquires the volume dataof the pointer by the volume acquisition device, and transmits the data to the processor. The processor acquires the information stored in a database and the analysis unit analyzes the acquired data.Thus, the automatic pointer identification system solves the problem that a conventional automatic pointer identification system requires manual pointer identification and thus results in a poor recognition effect and a waste of manpower and material resources.

Owner:HEFEI CHENGHUI ELECTRONICS

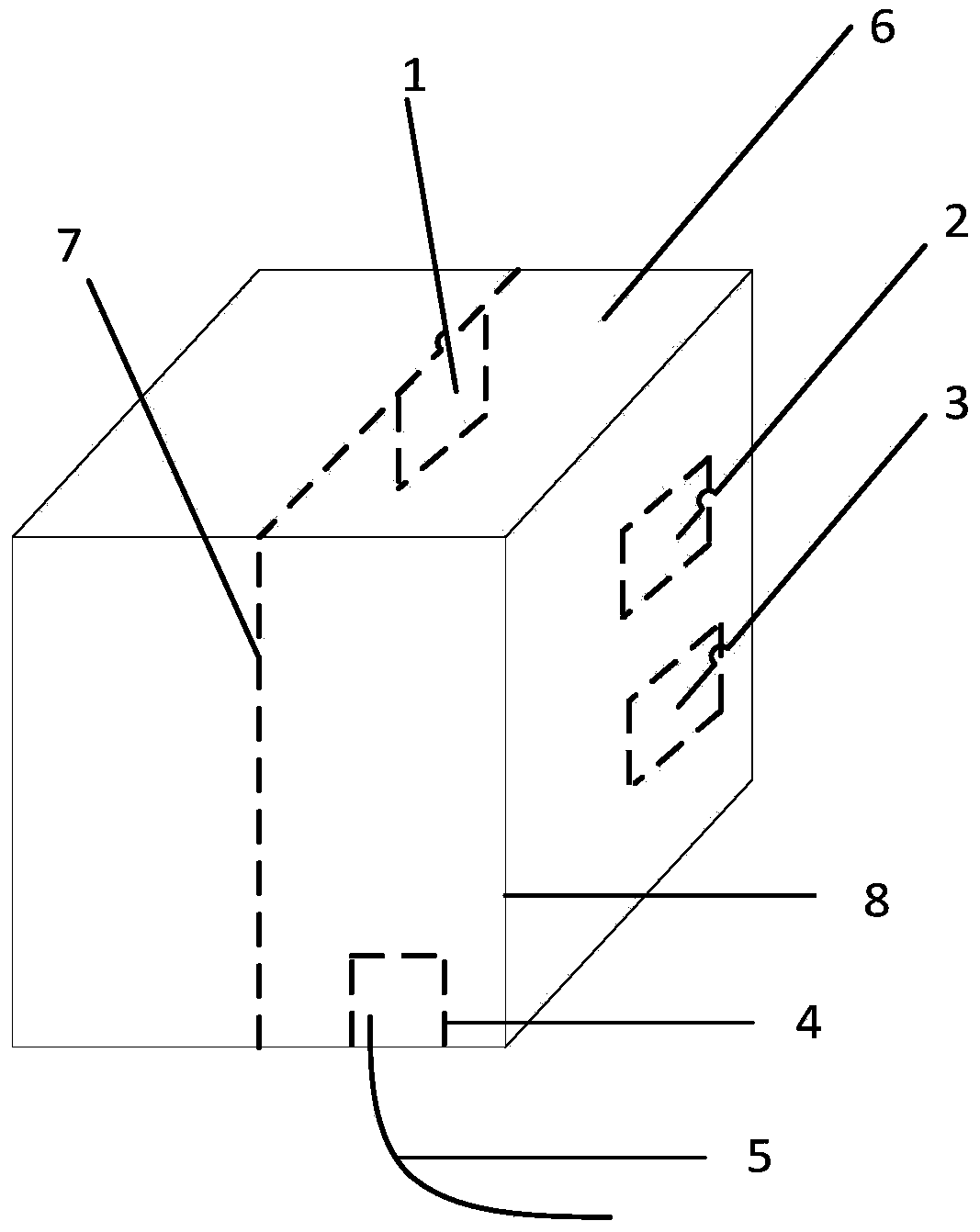

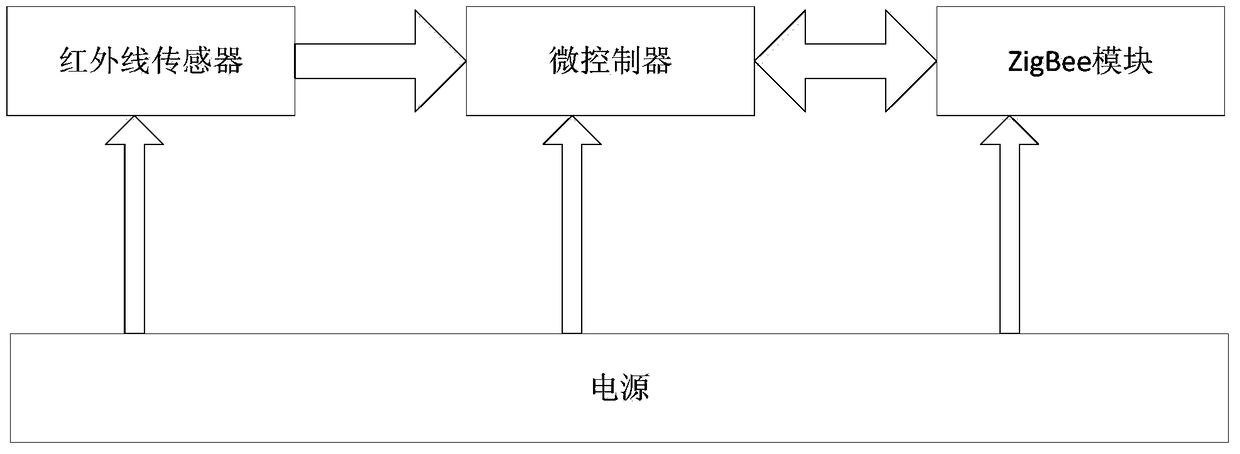

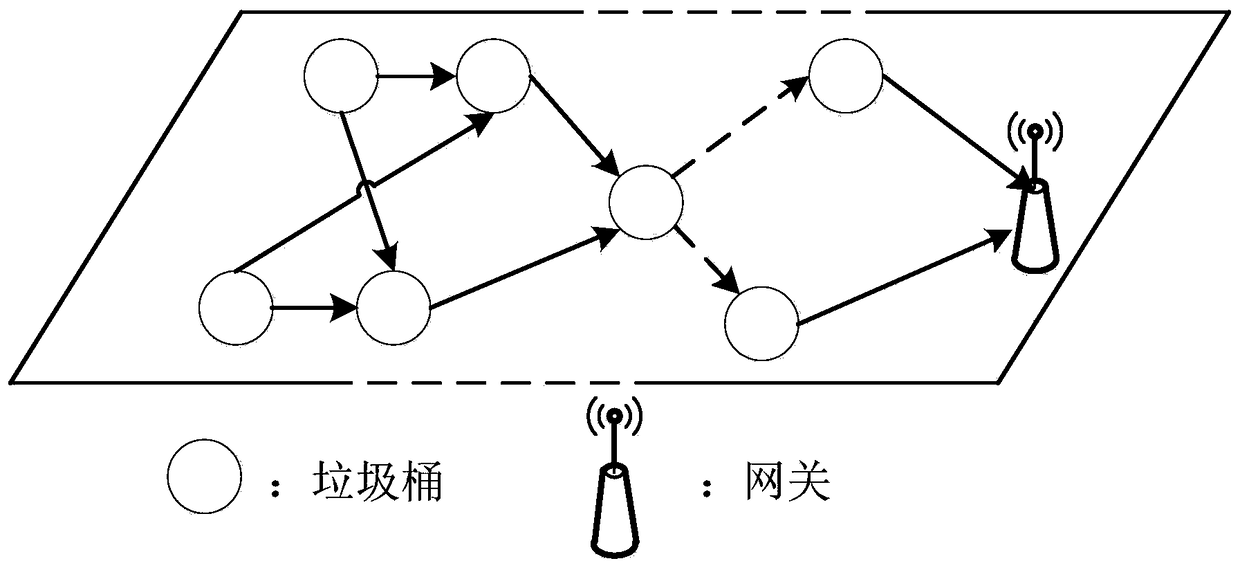

High-end office trash can management system and method based on wireless sensing technology

ActiveCN105223867BRealize the management systemReduce the use of manpower and material resourcesProgramme controlComputer controlMicrocontrollerWireless communication protocol

The invention discloses a system and a method for managing a high-grade office building dustbin based on wireless sensing technology. The system comprises an infrared sensor module, a microcontroller module, and a ZigBee module; the infrared sensor module senses the garbage entering into the dustbin; the microcontroller module performs timing on the infrared sensor which is blocked, and, after a certain time period is exceeded, transmits the number of the dustbin and filling information to a gateway; a ZigBee module adopts wireless control to transmit data to the gateway; the information collection is completed by the infrared sensor module; in the process of throwing garbage into the dustbin, firstly, the infrared sensor module senses that the garbage enters, and the microcontroller module performs time keeping; when the infrared sensor module is blocked over a certain time, the dustbin is full; at this time, the microcontroller module transmits the number and the signal of the dustbin which is full to the monitoring center through the ZigBee module wireless communication protocol; and, lastly, the monitoring center transmits the number of the dustbin which is full to a cleaner and notifies the cleaner to deal with the garbage.

Owner:NANJING UNIV OF POSTS & TELECOMM

An automatic stamping production line for electric pressure cooker

ActiveCN109732364BReasonable distributionNo accumulationOther manufacturing equipments/toolsHollow articlesRobot handPalletizer

The invention discloses an electric pressure cooker automatic stamping production line. The production line comprises a slicing machine, two oil hydraulic machines, two free-standing mechanical arms,a conveyor belt, a three-dimensional mechanical arm and a palletizing robot, wherein an oil wiper is arranged on one end of the slicing machine; the other end of the oil wiper is connected with the two oil hydraulic machines; the slicing machine, the oil wiper and the oil hydraulic machines are on the same horizontal direction; a two-arm free standing mechanical arm is arranged between the two oilhydraulic machines; and one of the oil hydraulic machines is externally connected with the conveyor belt through the corresponding free-standing mechanical arm. According to the production line, theslicing machine, the oil wiper, the oil hydraulic machines, the two-arm free-standing mechanical arm, the free-standing mechanical arms, the conveyor belt, the three-dimensional mechanical arm, a punching machine, a servo positioning conveyor belt and the palletizing robot are arranged, so that the problems that manpower and material resources are wasted when a stamping production line is in working, efficiency is low and equipment is not environmentally friendly enough are solved.

Owner:佛山市佛沃机器人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com