Textile washing equipment

A technology of washing equipment and body, applied in the field of textile washing, can solve the problems of fabric washing wrinkles, unobvious washing effect, inconvenient washing operation, etc., reduce the use of manpower and material resources, increase washing effect and washing efficiency, and realize automatic washing The effect of homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

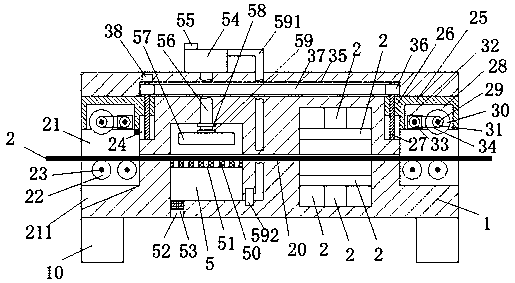

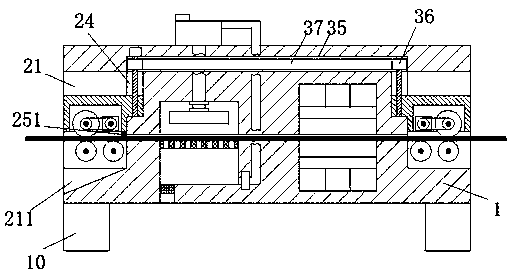

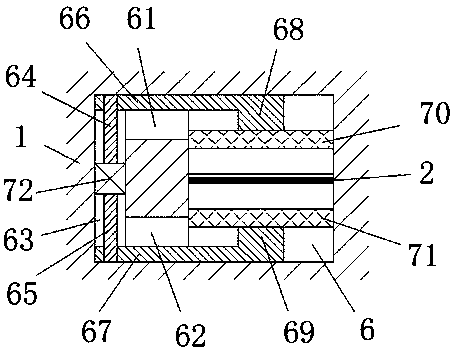

[0019] Such as Figure 1-Figure 3 As shown, a textile washing equipment of the present invention includes a body 1 and a base 10 fixedly arranged at the bottom of the body 1 and arranged symmetrically from left to right. Compression transmission components are symmetrically arranged on the left and right ends of the body 1, so that The compression transmission assembly includes an opening cavity 21 with an opening facing outwards. The lower part of the opening cavity 21 is rotatably provided with two symmetrical transmission rollers 22 through a first rotating shaft 23. In the inner end wall of the upper part of the opening cavity 21 A lifting sliding groove 24 is provided, and a driving groove 35 is connected between the two lifting sliding grooves 24 in the body 1, and a cloth conveying groove 20 is connected between the two openings 21 in the body 1 , the opening cavity 21 is provided with a pressing sliding block 25 that can slide up and down, and the inner end surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com