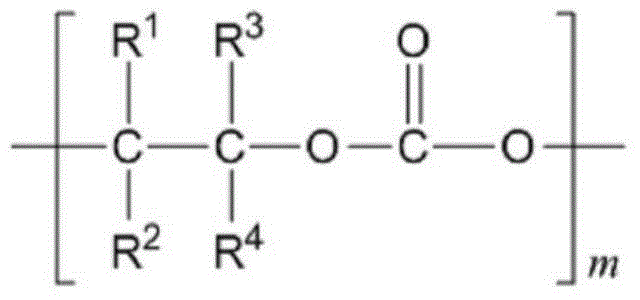

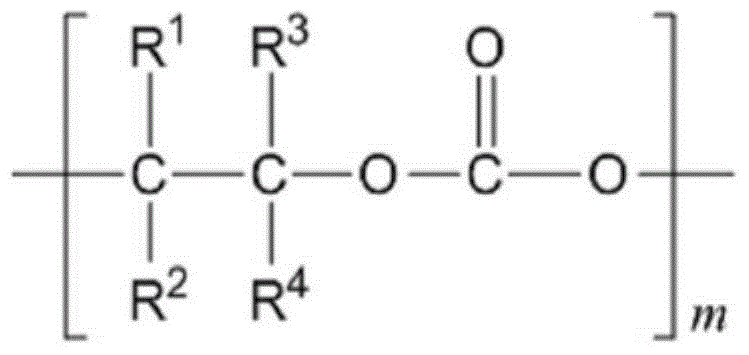

Resin composition containing polyalkylene carbonate

A technology of polyalkylene carbonate and resin composition, applied in the field of resin composition containing polyalkylene carbonate, polylactide and polyalkylacrylate, can solve the problem of reducing processability and product storage problems such as non-resistance, limited application, plate fusion-adhesion degree, etc., to achieve the effect of excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

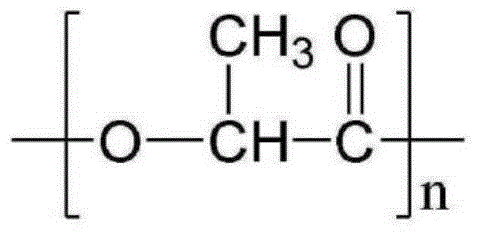

[0065] Polyethylene carbonate resins were prepared by copolymerizing ethylene oxide and carbon dioxide using a diethyl-zinc catalyst by the following method (Journal of Polymer Science B1969, 7, 287; Journal of Controlled release 1997, 49, 263).

[0066] 1 g of dry diethyl-zinc catalyst and 10 mL of dioxane solvent were charged into an autoclave reactor equipped with a stirrer, and then 0.1 g of purified water was added to the solution while stirring the solution. Next, carbon dioxide was passed into the reactor to a pressure of about 10 atm, and then the solution was stirred at 120° C. for 1 hour. Afterwards, 10 g of purified ethylene oxide was added, carbon dioxide was introduced again to a pressure of about 50 atm, and then the temperature was adjusted to 60° C. to carry out the reaction. After the reaction, unreacted ethylene oxide was removed under low pressure, and the reaction product was dissolved in dichloromethane solvent. Then, the dissolved reaction product was wa...

Embodiment 1

[0069] 94 g of polyethylene carbonate prepared in Preparation Example 1, 5 g of polylactide (PLA, weight average molecular weight: 230,000, manufactured by NatureWorks Corporation) and 1 g of polymethyl methacrylate (PMMA, weight average molecular weight: 86,000, manufactured by LGMMA Corporation) were mixed to prepare a resin composition.

[0070]Polyethylene carbonate was dried overnight in a vacuum oven at 40°C before use, and polylactide and polymethyl methacrylate were dried in a vacuum oven at 70°C for 4 hours before use .

[0071] The resin composition was formed into pellets using a twin-screw extruder (BA-19, manufactured by BAUTECH Corporation). The particles were dried overnight in a vacuum oven at 40° C. to prepare a dogbone-shaped sample. Then, the mechanical properties of the dogbone-shaped samples were measured using a universal testing machine (UTM).

Embodiment 2 to 6

[0073] A resin composition was prepared in the same manner as in Example 1 except that the contents of polyethylene carbonate, polylactide, and polymethylmethacrylate were changed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com