LCP film for FPC industry and preparation method thereof

A film, CH2CH3 technology, applied in the field of polymer films, can solve the problems of difficult to play the active role of stabilizers, violent volatilization and even decomposition, etc., to achieve the effect of improving signal transmission speed, low moisture absorption rate, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

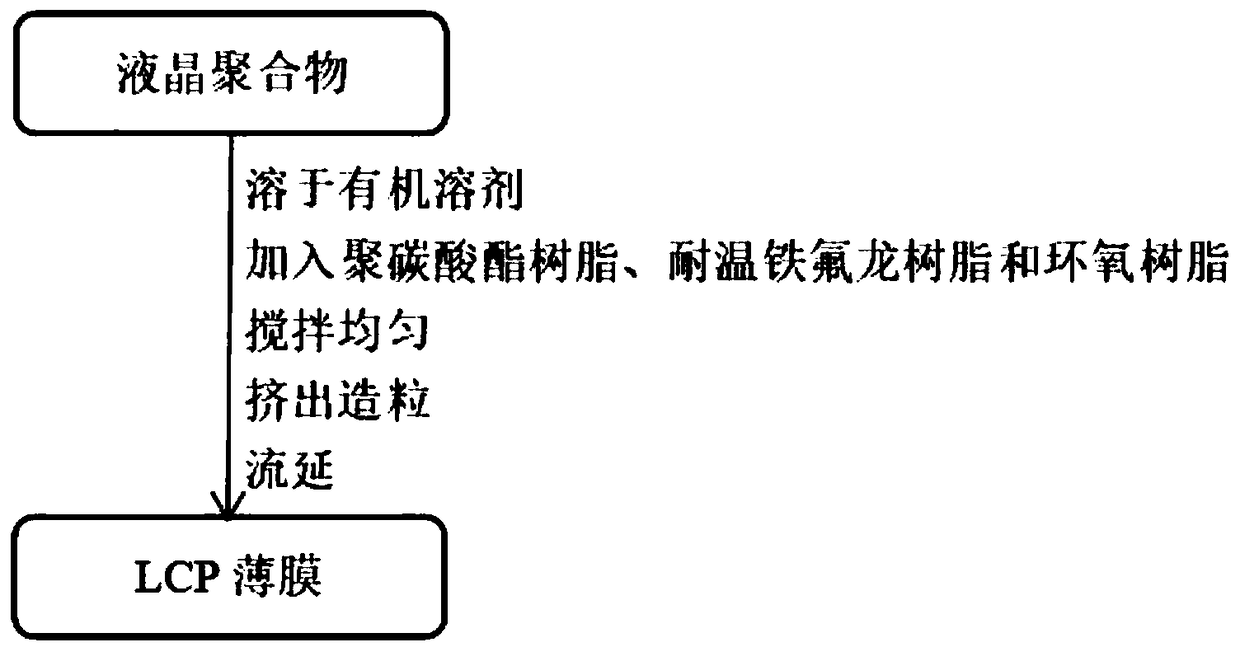

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 liquid crystal polymer

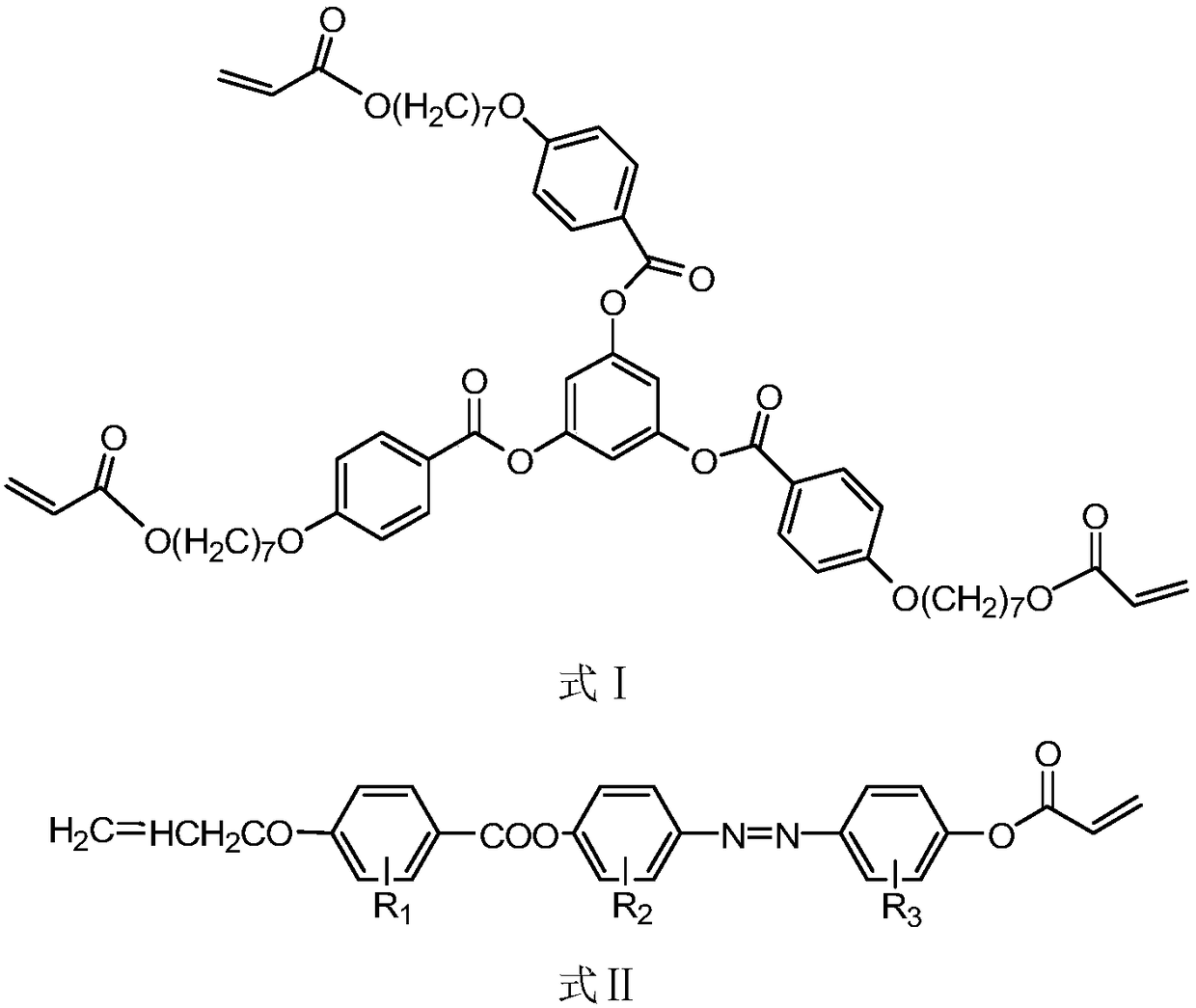

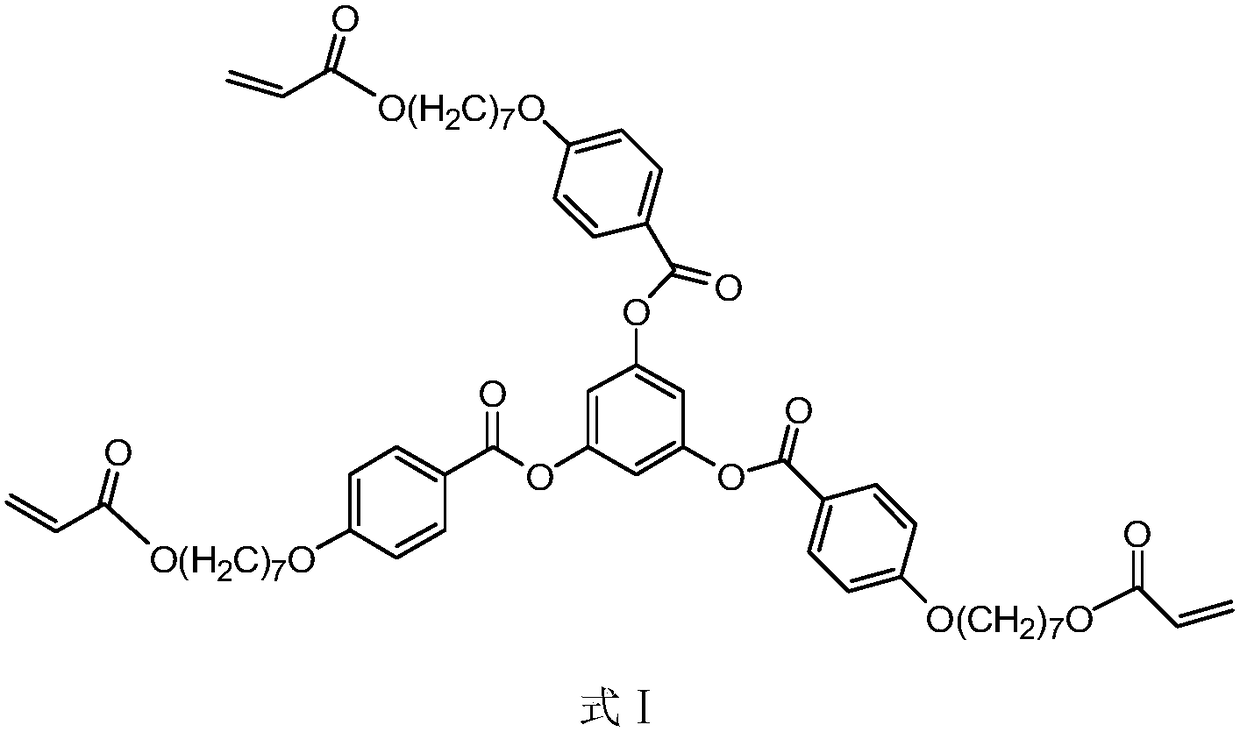

[0028] The synthesis of liquid crystal monomer shown in formula I:

[0029]

[0030] Dissolve 0.1mol of phloroglucinol and 0.32mol of p-hydroxybenzoic acid in 100mL of methanol, add a few drops of concentrated sulfuric acid dropwise, heat and react for 2 hours, filter with suction, wash the solid with ethanol, and obtain intermediate Ⅰ of the liquid crystal monomer shown in formula Ⅰ ;

[0031] Dissolve 0.1 mol of intermediate I of the liquid crystal monomer shown in formula I in 120 mL of ethanol, add dropwise 0.32 mol of 1,7-dibromoheptane, add 0.02 mol of KOH, heat to 60°C for 3 hours, filter with suction, and recrystallize from ethanol to obtain Intermediate II of the liquid crystal monomer shown in formula I;

[0032] Add 0.1mol intermediate II of the liquid crystal monomer shown in formula I, 0.3mol potassium acrylate, 2g tetrabutylammonium bromide, a small amount of hydroquinone and 160mL tetrahydrofur...

Embodiment 2

[0040] The preparation of embodiment 2 liquid crystal polymer

[0041] The preparation of liquid crystal polymer comprises the following steps: the liquid crystal monomer shown in 40g described formula I and 65g described formula II, 3g photoinitiator 2-dimethylamino-2-benzyl-1-[4-(4 -Morpholinyl)phenyl]-1-butanone and 1g of benzotriazole UV absorber are poured into the liquid crystal cell, at 95°C, at 2mW / cm 2 , induced polymerization under 365nm ultraviolet light, exposed for 30 minutes, and obtained liquid crystal polymer with a yield of 90%;

[0042] In the general structural formula of formula II, R 1 = H, R 2 = Cl, R 3 =H.

Embodiment 3

[0043] Preparation of Embodiment 3 Liquid Crystal Polymer

[0044] The preparation of liquid crystal polymer comprises the following steps: the liquid crystal monomer shown in 35g of said formula I and 62g of said formula II, 2g of photoinitiator 1-hydroxycyclohexyl phenyl ketone and 1g of salicylic acid ester ultraviolet absorbing The agent is poured into the liquid crystal cell, at 95°C, at 2mW / cm 2 , induced polymerization under 365nm ultraviolet light, exposed for 30min, and obtained liquid crystal polymer with a yield of 95%;

[0045] In the general structural formula of formula II, R 1 = H, R 2 =OCH 3 , R 3 =Br.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com