Low-thermal-expansion cordierite-based microcrystalline glass material and preparation method thereof

A technology of low thermal expansion and glass-ceramic, applied in electrical components, circuits, electric solid devices, etc., can solve the problems of thermal expansion coefficient mismatch, poor mechanical properties, large dielectric loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to the formula: MgO is 15wt%, Al 2 O 3 26wt%, SiO 2 50wt%, ZrO 2 6wt%, B 2 O 3 1wt%, K 2 O is 2wt%, accurately calculate the weight of the corresponding raw materials, after accurate weighing, ball mill for 2 hours to make it evenly mixed; after drying, put the mixture in a crucible to melt, heat up to 1400°C for 1.5 hours, and after melting is complete Water quenching; then the obtained glass slag is wet ball milled, dried to obtain glass powder, ball milled with deionized water as the medium for 6 hours, and dried to obtain a uniformly dispersed powder; after the powder is granulated and dry pressed, Sintering at 900°C and holding for 1 hour, the low thermal expansion cordierite-based glass-ceramic material is obtained.

[0027] The low thermal expansion cordierite-based glass-ceramic material prepared in this embodiment, Mg 2 Al 4 Si 5 O 18 The content of phase is 73.4%, (Mg Al 2 Si 3 O 10 ) 0.6 The content of the phase is 19.1%. The performance indicators are...

Embodiment 2

[0029] According to the formula: MgO is 16wt%, Al 2 O 3 27wt%, SiO 2 49wt%, ZrO 2 5wt%, B 2 O 3 2wt%, K 2 O is 1wt%, accurately calculate the weight of the corresponding raw material, after accurate weighing, ball mill for 2 hours to make it evenly mixed; after drying, put the mixture in a crucible to melt, heat up to 1400 ℃ for 2 hours, and after melting is complete Water quenching; then the obtained glass slag is wet ball milled, dried to obtain glass powder, ball milled with deionized water as the medium for 6 hours, and dried to obtain a uniformly dispersed powder; after the powder is granulated and dry pressed, Sintering at 900°C and holding for 1.5 hours, the low thermal expansion cordierite-based glass-ceramic material is obtained.

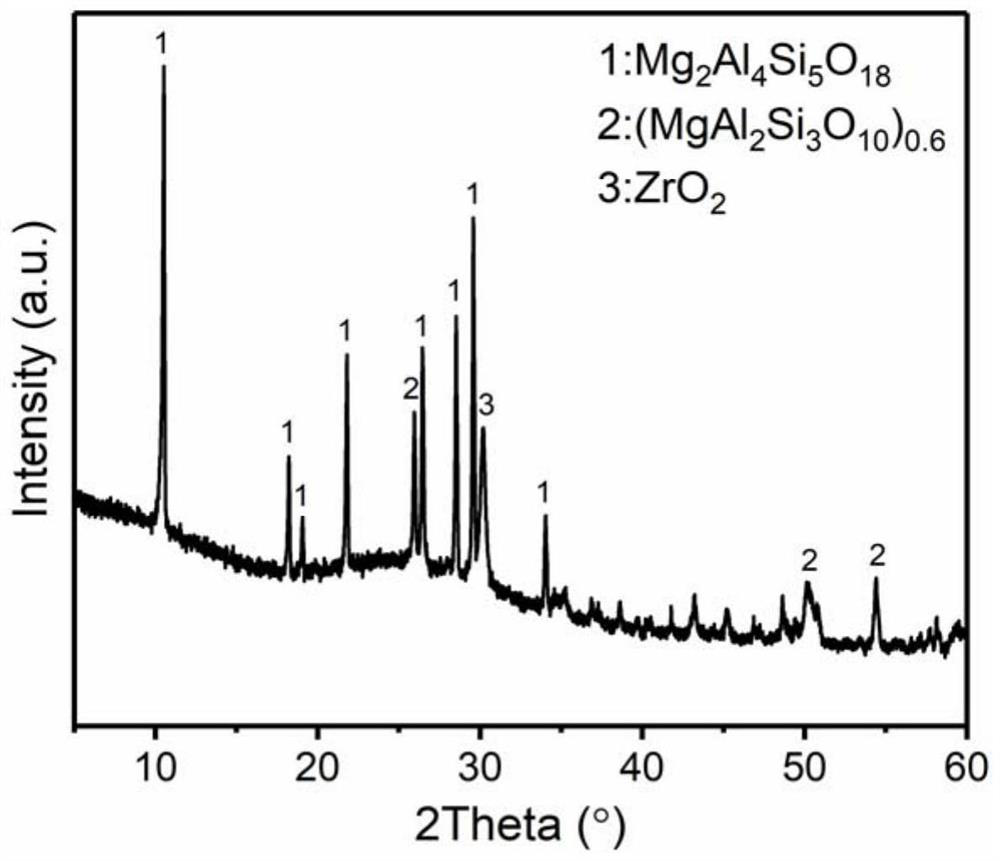

[0030] The low thermal expansion cordierite-based glass-ceramic material prepared in this embodiment, the XRD pattern is as figure 1 As shown, the main crystal phase is Mg 2 Al 4 Si 5 O 18 , The subcrystalline phase is (MgAl 2 Si 3 O 10 ) 0.6 A...

Embodiment 3

[0032] According to the formula: MgO is 17wt%, Al 2 O 3 28wt%, SiO 2 47wt%, ZrO 2 4wt%, B 2 O 3 1wt%, K 2 O is 3wt%, accurately calculate the weight of the corresponding raw material, after accurate weighing, ball mill for 3 hours to make it evenly mixed; after drying, put the mixture in a crucible to melt, heat up to 1450℃ for 1 hour, and after melting is complete Water quenching; then the obtained glass slag is wet ball milled, dried to obtain glass powder, ball milled with deionized water as the medium for 7 hours, and dried to obtain a uniformly dispersed powder; after the powder is granulated and dry pressed, Sintered at 925°C and kept for 1.5 hours to obtain a low thermal expansion cordierite-based glass-ceramic material.

[0033] The low thermal expansion cordierite-based glass-ceramic material prepared in this embodiment, Mg 2 Al 4 Si 5 O 18 The content of phase is 68.4%, (MgAl 2 Si 3 O 10 ) 0.6 The phase content is 22.6%. The performance indicators are: dielectric consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com