Kitchen automatic fire extinguishing device achieving zone control

A technology of automatic fire extinguishing and partition control, which is applied in fire rescue and other fields, and can solve the problems of large mechanical drive force, inaccuracy, and easy breakage of fuses, and achieve the effect of rapid signal transmission, reduced installation costs, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

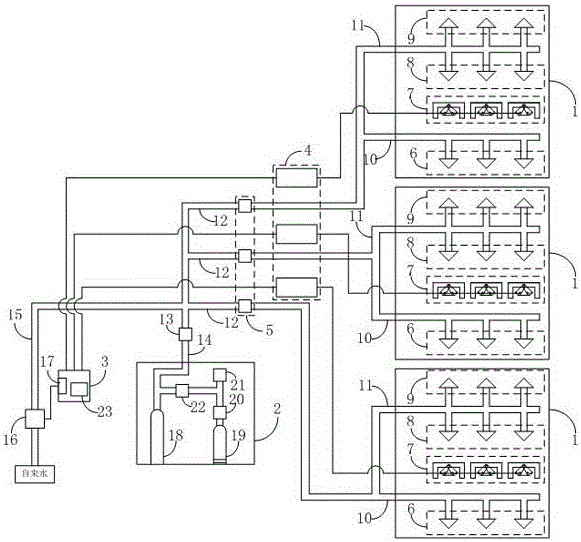

[0031] Such as figure 1 As shown, a schematic diagram of the system structure of a kitchen automatic fire extinguishing device with partition control according to the present invention, including a plurality of fire extinguishing mechanisms 1, a fire extinguishing box 2 and a control box 3, wherein it also includes a plurality of fire signal transmission devices 4, fire signal transmission devices The number of 4 is the same as that of the fire extinguishing mechanism 1, the input end of the fire signal transmission device 4 is connected to the fire extinguishing mechanism 1, and the output end is connected to the control box 3;

[0032] The fire extinguishing mechanism 1 includes a first fire extinguishing pipe 10 and a plurality of temperature sensors 7 arranged above the stove, and a second fire extinguishing pipe 11 arranged in the flue. The first fire extinguishing pipe 10 is provided with a plurality of The first nozzle 6 for fire extinguishing, the second fire extinguis...

Embodiment 2

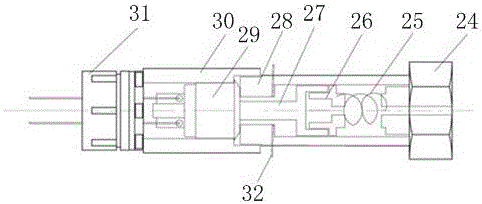

[0038] Such as figure 2 As shown, the structure diagram of the fire signal transmission device in a kitchen automatic fire extinguishing device with partition control according to the present invention, the fire signal transmission device 4 includes a fixing part 24, a spring compression part 28, a switch fixing part 30 and a bushing 31 connected in sequence , the spring compression part 28 is internally provided with a switch starter and a spring 25, the switch starter includes a wire fixing part 26 and a driving part 27, the spring 25 is located between the wire fixing part 26 and the fixing part 24 and the wire fixing part 26 and the fixing part Parts 24 are provided with through holes, and spring compression parts 28 are provided with small holes, which are provided with inserted safety pins 32, and switch fixing parts 30 are internally provided with switches 29; fixing parts 24, spring compression parts 28, switches Both the fixing part 30 and the sleeve pipe 31 are conn...

Embodiment 3

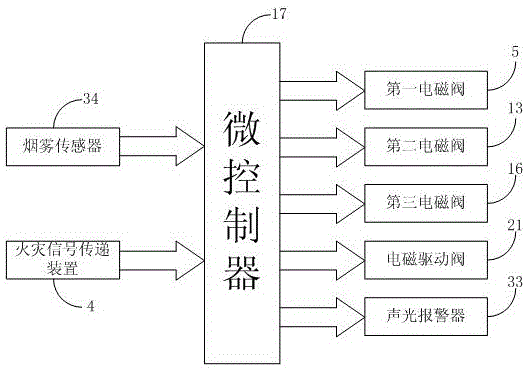

[0041] The fire extinguishing box 2 is provided with a medicine bottle 18 and a nitrogen tank 19, the mouth of the nitrogen tank 19 is connected with a bottle head valve 20, and the bottle head valve 20 is connected with an electromagnetic driver 21, and the medicine bottle 18 and the nitrogen tank 19 are connected with a reducing valve. Pressure valve 22, medicament bottle 18 is communicated with described fire extinguishing main pipeline 14 by second electromagnetic valve 13, and electromagnetic driver 21 is connected with output end of microcontroller 17; Control box 3 also comprises audible and visual alarm 33, audible and visual alarm 33 Connect with microcontroller 17 output terminals; Smoke sensor 34 is arranged in the flue, and smoke sensor 34 is connected with the input terminal of microcontroller 17, as image 3 As shown, the circuit principle block diagram of a kind of partition control kitchen automatic fire extinguishing device of the present invention.

[0042] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com