Novel construction method of biodegradable porous PHBV/PPC (poly (3-hydrobutyrate-3-hydroxyvalerate)/polypropylene carbonate) composite scaffold

A technology of blends and porogens, used in food packaging, medical devices, drug sustained release or tissue engineering, and biodegradable materials to achieve the effects of improving brittleness, adjustable degradation performance, and improving surface hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

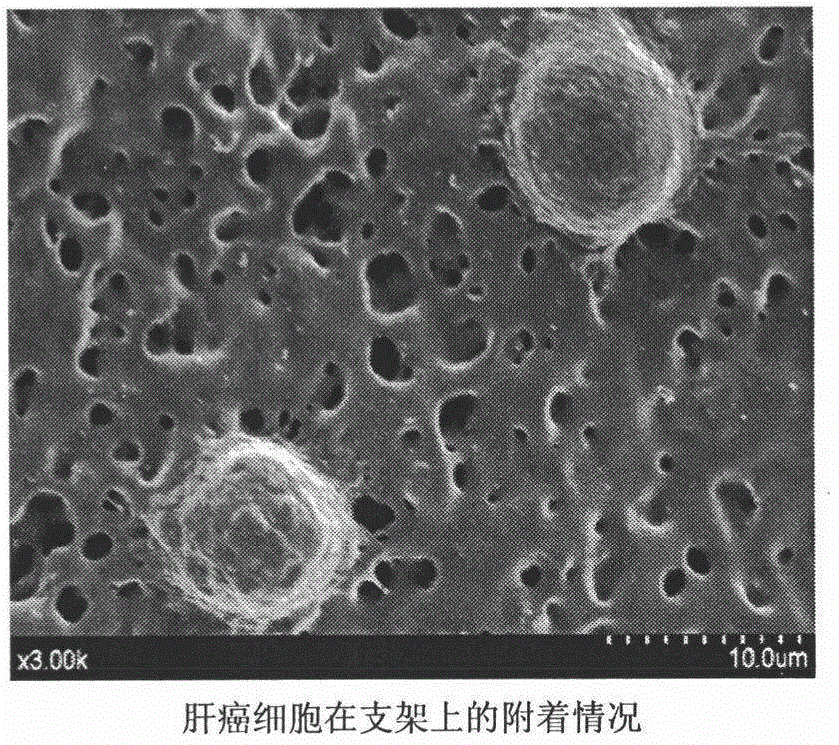

[0026]MA, DCP and PPC are mixed at 30rpm in a Haake mixer at 160°C to obtain maleic anhydride-terminated PPC (MA-PPC); PHBV is mixed with GMA (5%) and DCP (0.5%) at 165°C to obtain GMA modified PHBV, MA-PPC (10%), GMA modified PHBV (10%), and porogen NaCl (80%) are reactively melt blended at 165°C, hot pressed into sheets, and cold pressed. The blended product was soaked in distilled water, and the water-soluble components were removed by particle ultrasonic leaching in a 37°C water bath, and the weight of the scaffold was weighed until there was no change to determine the complete dissolution of salt ions. Finally, it was soaked in 2mol / L NaOH solution for 90 minutes, washed with water until neutral, and freeze-dried to obtain a porous PHBV / PPC composite scaffold with a porosity of 71.34%. The liver cancer cells were fixed on the support, and the adhesion and growth state of the cells on the surface of the material was observed with a scanning electron microscope (SEM) (as sh...

Embodiment 2

[0028] MA, DCP and PPC were mixed in a 30rpm, 160°C Haake mixer to obtain MA-capped PPC (MA-PPC); PHBV was mixed with GMA (5%) and DCP (0.5%) at 165°C to obtain GMA modified For PHBV, MA-PPC (3%), PHBV-GMA graft (7%), and porogen NaCl (90%) are reactively melt-blended at 165°C, hot-pressed into tablets, and cold-pressed. The blended product was immersed in distilled water, and the water-soluble components were ultrasonically removed in a 37°C water bath by particle ultrasonic leaching, and the weight of the scaffold was weighed until there was no change to determine the complete dissolution of salt ions. Finally, it was soaked in 2mol / L NaOH solution for 90 minutes, washed with water until neutral, and freeze-dried to obtain a porous PHBV / PPC composite scaffold with a porosity of 82.79%, an appropriate in vitro degradation cycle, and excellent mechanical properties. It can be used as a tissue engineering carrier material. For tissue repair and reconstruction.

Embodiment 3

[0030] MA, DCP and PPC were mixed in a 30rpm, 160°C Haake mixer to obtain MA-capped PPC (MA-PPC); PHBV was mixed with GMA (5%) and DCP (0.5%) at 165°C to obtain GMA modified For PHBV, MA-PPC (7%), PHBV-GMA graft (3%), and porogen NaCl (90%) are reactively melt-blended at 165°C, hot-pressed into tablets, and cold-pressed. The blended product was immersed in distilled water, and the water-soluble components were ultrasonically removed in a 37°C water bath by particle ultrasonic leaching, and the weight of the scaffold was weighed until there was no change to determine the complete dissolution of salt ions. Finally, it was soaked in 2mol / L NaOH solution for 90 minutes, washed with water until neutral, and freeze-dried to obtain a porous PHBV / PPC composite scaffold with a porosity of 82.9%, an appropriate in vitro degradation cycle, and excellent mechanical properties. It can be used as a tissue engineering carrier material. For tissue repair and reconstruction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com