Solid environment-friendly foaming agent and preparation method thereof

A foaming agent and environmentally friendly technology, applied in the field of solid environmentally friendly foaming agent and its preparation, can solve the problems of poor stability and large pollution, achieve low cost, good bonding performance, and avoid the effect of overloading equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

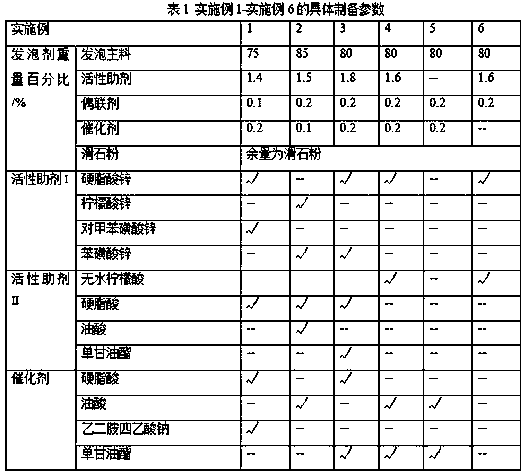

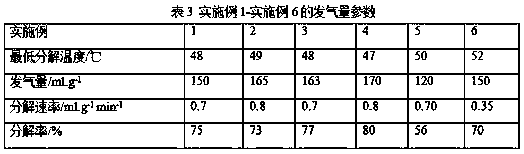

Embodiment 1

[0040] The preparation method of above-mentioned embodiment 1 a kind of solid environment-friendly blowing agent, comprises the steps:

[0041] S1 Raw material preparation: prepare the main foaming material, active additives and talcum powder according to the weight ratio for use;

[0042]S2 mixing and stirring: put the raw materials prepared in step S1 into the same container and stir to mix evenly;

[0043] S3 Pulverize the coating: After the raw materials mixed in the step S2 are pulverized twice, add the catalyst and stir for 2 minutes, then add the coupling agent and stir for 8 minutes to obtain the finished product.

[0044] Specifically, the stirring speed in the S2 step is 1600r / min; the stirring speed in the S3 step is 1800r / min.

[0045] Specifically, the two pulverization steps in the step S3 are as follows: firstly, the mixed raw materials are put into a mechanical pulverizer for pulverization for 30 minutes, and then sent to a jet pulverizer for pulverization for...

Embodiment 2

[0047] The preparation method of above-mentioned embodiment 2 a kind of solid environment-friendly blowing agent, comprises the steps:

[0048] S1 Raw material preparation: prepare the main foaming material, active additives and talcum powder according to the weight ratio for use;

[0049] S2 mixing and stirring: put the raw materials prepared in step S1 into the same container and stir to mix evenly;

[0050] S3 Pulverize the coating: After the raw materials mixed in the step S2 are pulverized twice, add the catalyst and stir for 3 minutes, then add the coupling agent and stir for 10 minutes to obtain the finished product.

[0051] Specifically, the stirring speed in the S2 step is 1400r / min; the stirring speed in the S3 step is 1500r / min.

[0052] Specifically, the two pulverization steps in the step S3 are as follows: first, the mixed raw materials are put into a mechanical pulverizer for pulverization for 20 minutes, and then sent to a jet pulverizer for pulverization for...

Embodiment 3

[0054] The preparation method of above-mentioned embodiment 3 a kind of solid environment-friendly blowing agent, comprises the steps:

[0055] S1 Raw material preparation: prepare the main foaming material, active additives and talcum powder according to the weight ratio for use;

[0056] S2 mixing and stirring: put the raw materials prepared in step S1 into the same container and stir to mix evenly;

[0057] S3 Pulverize the coating: After the raw materials mixed in the step S2 are pulverized twice, add the catalyst and stir for 3 minutes, then add the coupling agent and stir for 9 minutes to obtain the finished product.

[0058] Specifically, the stirring speed in the S2 step is 1500r / min; the stirring speed in the S3 step is 1600r / min.

[0059] Specifically, the two pulverization steps in the step S3 are as follows: first, the mixed raw materials are put into a mechanical pulverizer for pulverization for 25 minutes, and then sent to a jet pulverizer for pulverization for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com