Organosilicon ingredient toughened methyl silicone resin and preparation method thereof

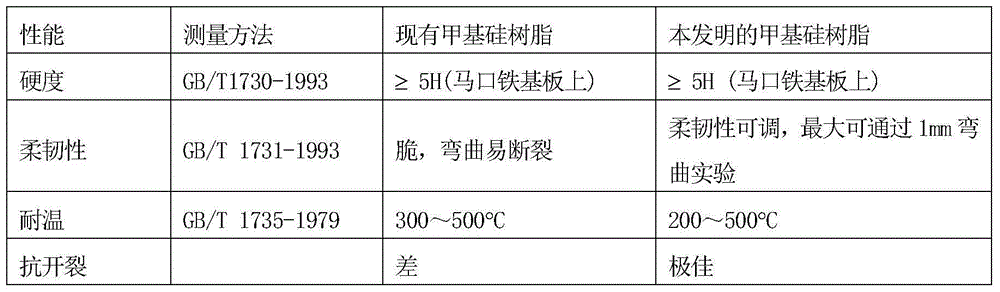

A technology of methyl silicone resin and organosilicon, which is applied in the field of methyl silicone resin and its preparation, can solve problems such as easy cracking and cracks, and achieve the effects of good heat and humidity resistance, simple preparation process, high hardness and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of silicone component toughened methyl silicone resin

[0039] ① Prepare the following components: 15g deionization, 1g acid catalyst acetic acid, 40g methyltrimethoxysilane, 5g phenyltrimethoxysilane, 0.1g curing agent tetramethylammonium hydroxide, 0.1g leveling agent, Save for later use;

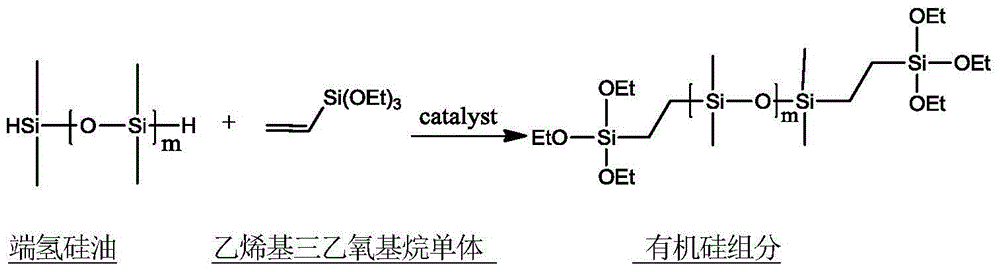

[0040] ②Put a 250mL round-bottomed flask in a water bath, add 24 g of vinyltriethoxysiloxane and 1.44 g of Speier catalyst in sequence, stir in a water bath at room temperature, and then dropwise add 80 g of terminal Hydrogen silicone oil, control the temperature of the reaction solution ≤ 80°C, after the dropwise addition, continue to stir for 2 hours, then continue to react at 80°C for 2 hours to obtain the organosilicon component, save it for later use, wherein the amount of vinyl siloxane added is the same as The molar ratio of SiH groups in hydrogen-terminated silicone oil is 1:1; the amount of platinum catalyst is 0.03wt% of the amount of vinyl siloxane...

Embodiment 2

[0045] Example 2 Preparation of silicone component toughened methyl silicone resin

[0046] ① Prepare the following components: 14.8g acidic silica sol silica, 1.2g acid catalyst acetic acid, 46g methyltriethoxysilane, 5g phenyltrimethoxysilane, 1.2g silane coupling agent γ-(2,3 -propylene oxide) propyltrimethoxysilane, 0.1g curing agent tetramethylammonium hydroxide, 0.1g leveling agent, save for subsequent use;

[0047] 2. Prepare the organosilicon component by the same method as in Example 1, and save it for future use;

[0048] ③In a 100ml round bottom flask, add the acidic silica sol silicon prepared in step ①, acidic catalyst acetic acid, methyltriethoxysilane, phenyltrimethoxysilane, and silane coupling agent in sequence, and stir and mix at room temperature After 4 hours, add 4g of the silicone component prepared in step ②, and then stir and react at 80°C for 2 hours to obtain a hydrolyzed prepolymerized product, add the curing agent tetramethylammonium hydroxide and ...

Embodiment 3

[0050] Example 3 Preparation of silicone component toughened methyl silicone resin

[0051] ① Prepare each component: 14.8g acidic silica sol silica, with an average particle size of 12nm, 1.2g acidic catalyst acetic acid, 46g methyltriethoxysilane, 5g phenyltrimethoxysilane, 1.2g coupling agent γ-( 2,3-propylene oxide) propyltrimethoxysilane, 40mg curing agent aluminum acetylacetonate, 0.1g leveling agent, save for later use;

[0052] 2. Prepare the organosilicon component by the same method as in Example 1, and save it for future use;

[0053] ③In a 100ml round bottom flask, first add 20g of ethanol and 2g of acetic acid aqueous solution with a pH value of 4~5, then add 2g of the organic silicon component prepared in step ②, stir at room temperature for 2 hours, then continue at 80°C React for 2 hours to obtain the hydrolysis prepolymerization product of the organosilicon component; in another 100ml round bottom flask, add the acidic silica sol, acidic catalyst, methyltriet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com