Inner plugging air bag for leakage of risk source pipeline and quick plugging method thereof

A pipeline leakage and risk source technology, which is applied in the pipeline leakage sealing device and its sealing field, to achieve the effects of speeding up the sealing, easy processing and manufacturing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

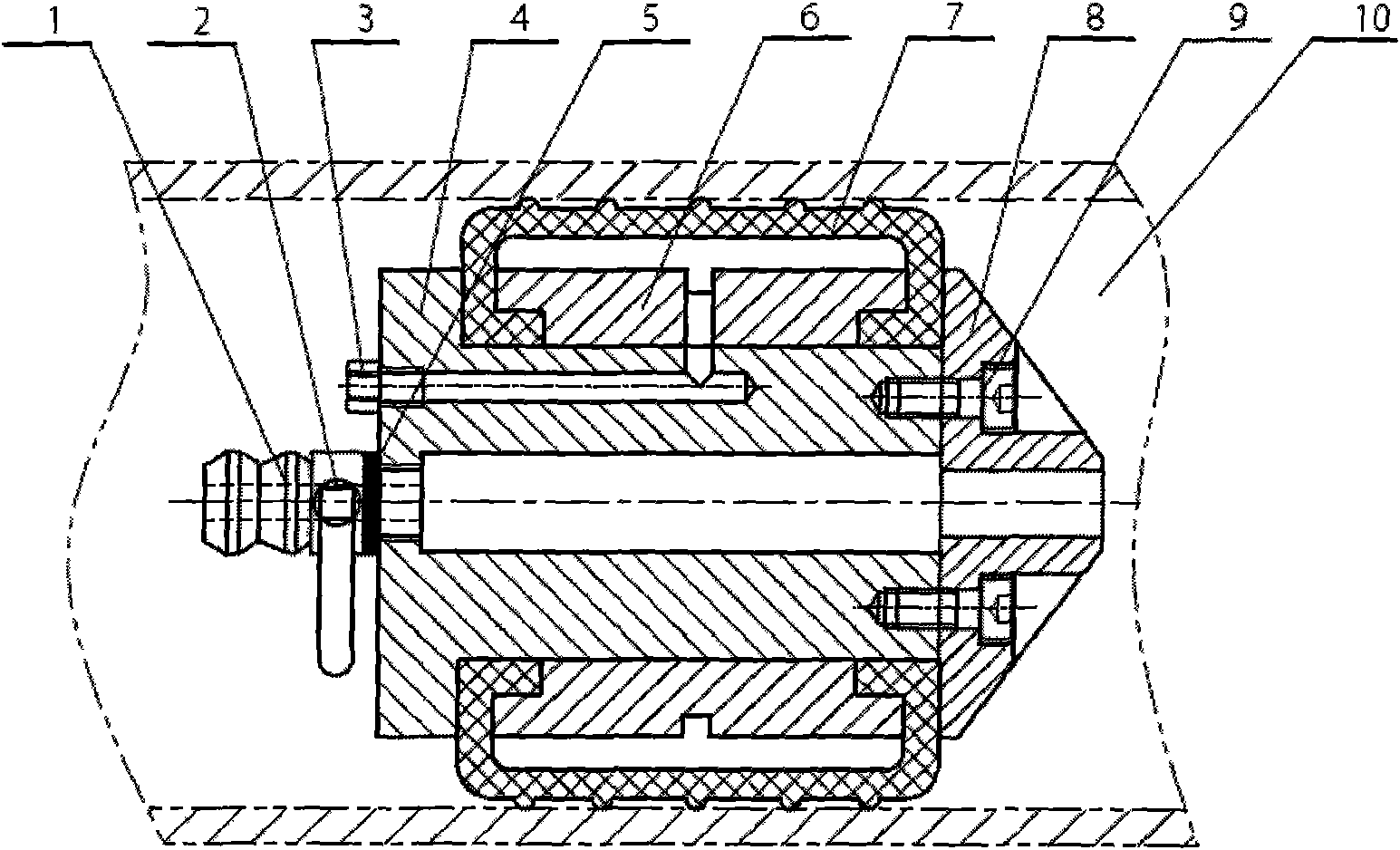

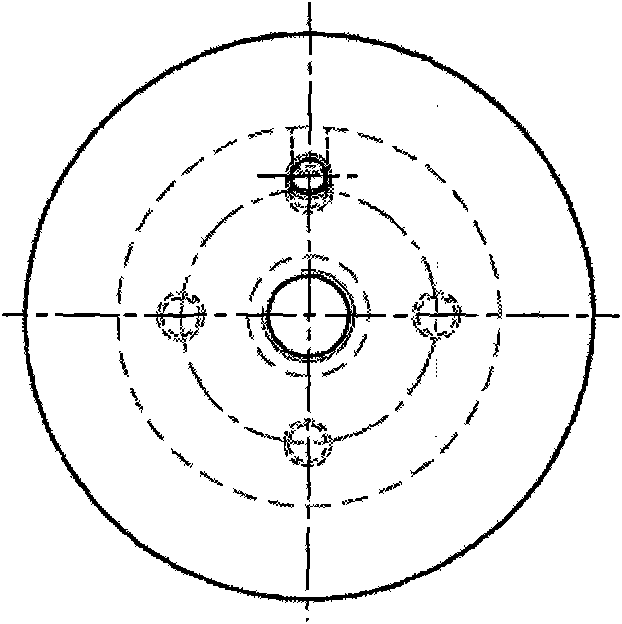

[0028] Such as Figure 1-Figure 9 According to the present invention, a risk source pipeline leakage internal plugging diversion air bag and its plugging method are implemented, and its mechanical structure includes a sealing mechanism, a diversion mechanism, a holding mechanism and a fixing structure.

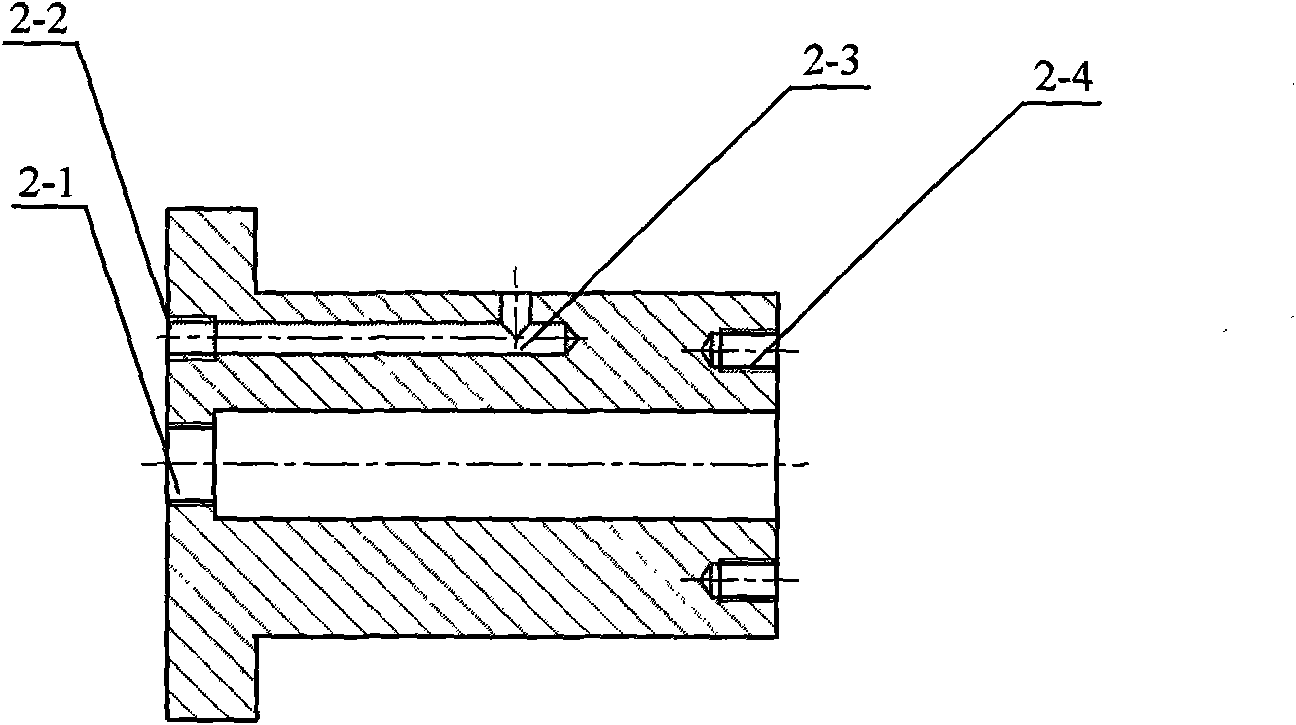

[0029] Among them, the sealing mechanism includes a blocking air bag 7; the diversion mechanism includes a diversion tube nozzle 1, a diversion ball valve 2, and a sealing gasket 5, wherein the diversion tube nozzle can be externally connected to the diversion tube; the holding mechanism includes a hollow shaft sleeve 4 and its The inflation joint 3 on the left end face; the fixing mechanism includes an air bag compression sleeve 6 and a tapered flange cover 8 .

[0030] Wherein, the connection of the diversion mechanism is through the diversion pipe joint 1 and the diversion ball valve 2 through threaded connection, and then the diversion ball valve thread on the left end sur...

Embodiment 2

[0032] Such as Figure 1-Figure 9 , implementing a kind of risk source pipeline leakage internal plugging diversion air bag and its plugging method of the present invention, the plugging method is that after the sealing mechanism, the diversion mechanism, the holding mechanism and the fixed structure are installed together, at first the diversion Connect the diversion tube on the pipe joint 1, and connect the inflation tube on the inflation joint 3. Install the whole set of internal blocking airbags in the risk source pipeline 10, open the diversion ball valve 2, then inflate into the blocking airbag 7 through the inflation tube, and finally close the diversion ball valve 2, so as to realize the rapid sealing of the risk source pipeline 10. Divert if necessary. Open diversion ball valve 2 with special tool and get final product.

[0033] The pipe internal plugging and diversion airbag can be directly applied to the leakage of the straight mouth of the pipeline. In the case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com