Mixed grouting device for blocking high-pressure groundwater and mixing method grouting process therefor

A groundwater and mixing method technology, applied in protection devices, underground chambers, shaft equipment, etc., can solve the problems of difficult to control the solidification time of the slurry, high cost, and insignificant grouting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] What this embodiment adopts is the most commonly used grouting material, cement and water glass, and cement is strong and wear-resistant, is the most commonly used grouting material, and water glass and cement mixing can accelerate grout solidification.

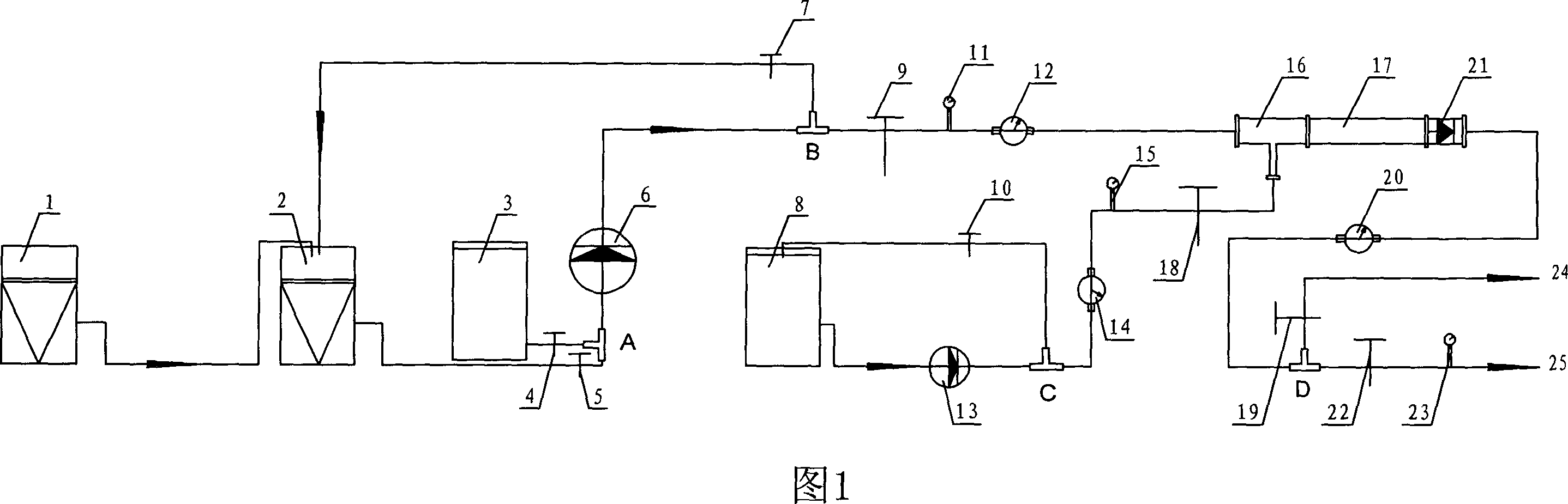

[0020] The mixing grouting device used to block high-pressure groundwater of the present invention is shown in Fig. 3, and this device is actually the system that is made up of a plurality of equipments, contains high-speed mixer 1, and it is communicated with cement storage tank 2, and the other end of this storage tank The valve B5 is connected with the tee A, and the other inlet of the tee is connected with the water storage tank 3 through the valve A4. The outlet of the tee A is connected with a high-pressure mud pump 6, and its output end is connected with the tee B. One output end communicates with the top of the slurry storage tank 2 through the slurry return valve a7, and the other output end of the tee B is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com