Semiconductor lamp with heat dissipation support

A technology of heat dissipation bracket and semiconductor, which is applied in semiconductor devices of light-emitting elements, lighting and heating equipment, cooling/heating devices of lighting devices, etc., which can solve the problems of affecting heat dissipation efficiency and poor circulation of hot air to the outside, so as to facilitate cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

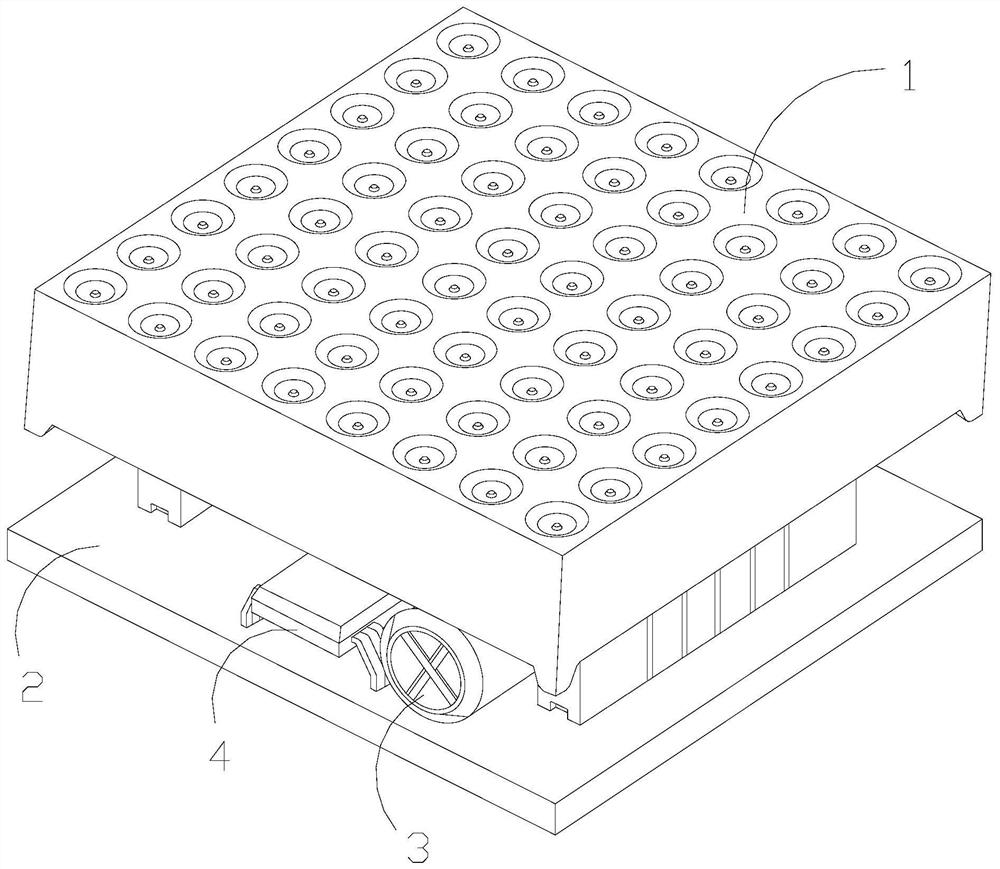

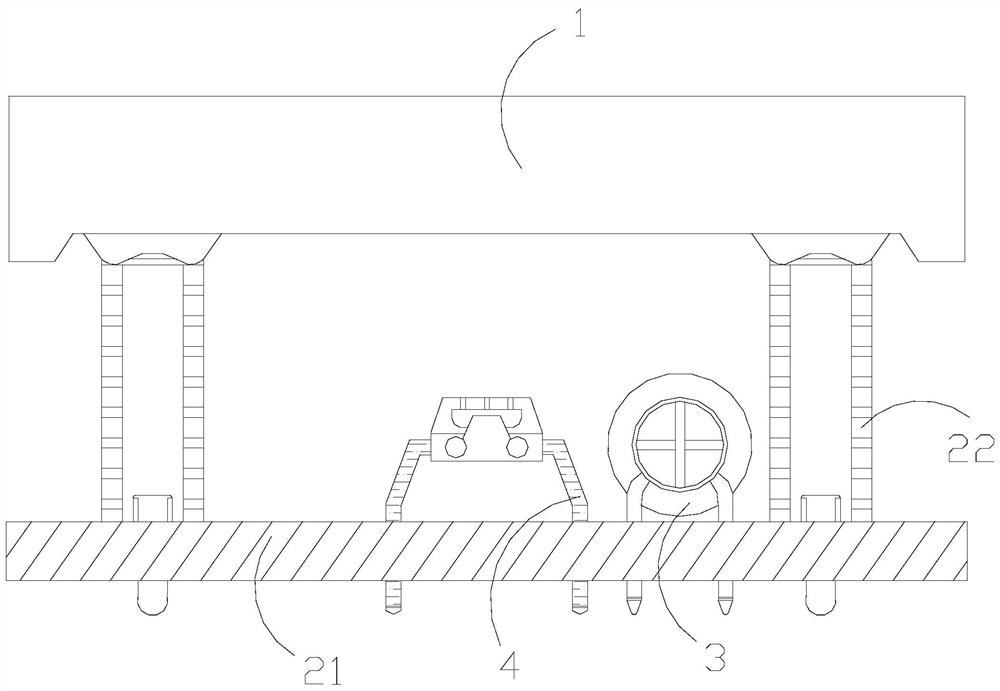

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The invention provides a semiconductor lamp with a heat dissipation bracket, which is structured with a lamp board 1, a bearing board 2, a control source 3, and a circuit board 4, the lamp board 1 is located above the bearing board 2, and the circuit board 4 is installed on The top end of the carrier board 2 , the control source 3 is located beside the circuit board 4 .

[0033] The bearing plate 2 is provided with a bottom plate 21 and a bracket 22 , and the lower section of the bracket 22 passes through both sides of the bottom plate 21 and is movably matched.

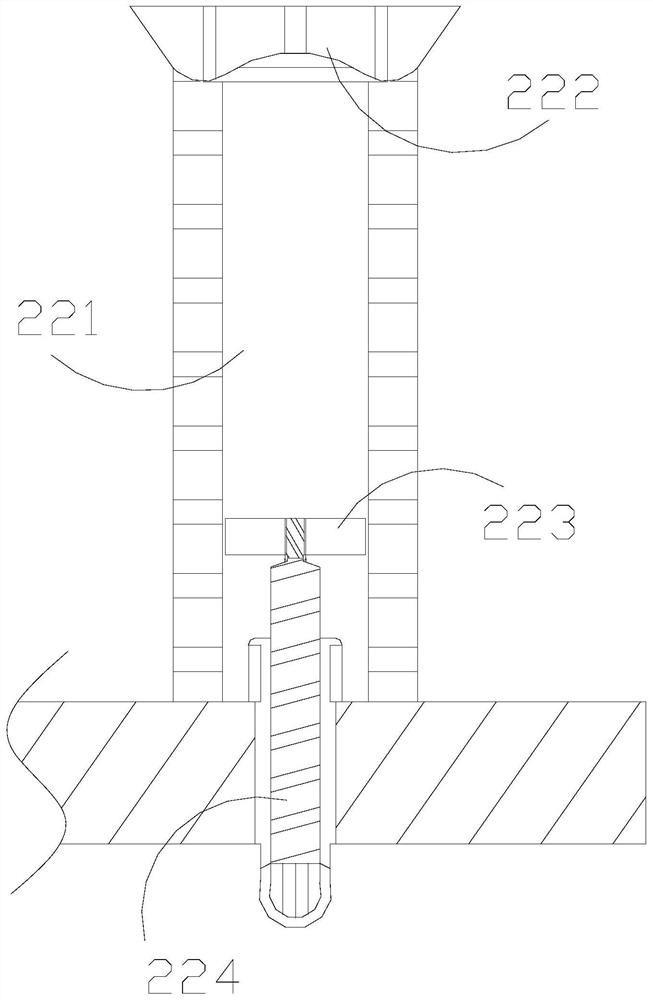

[0034] Wherein, the bracket 22 is provided with a heat dissipation column 221, an adapter 222, a displacement block 223, and a lifting column 224. The adapter 222 and the heat dissipation column 221 are an integrated structure and are located at its top position. The displacement block 223 is movably connected. Cooperating with the upper end of the li...

Embodiment 2

[0041] as attached Figure 8 to attach Figure 9 Shown:

[0042] Wherein, the wiping ball a24 is provided with an outer ring w1, an expansion ring w2, an engaging block w3, a pressing ball w4, and a spring w5. The engaging block w3 is connected to the outer end of the expansion ring w2. The block w3 moves inside the outer ring w1, the engaging block w3 runs through the outer ring w1, the pressing ball w4 is located at the inner end of the expansion ring w2, and the two ends of the spring w5 are respectively connected to the expansion ring w2, the top The pressure ball w4 is connected and movably matched. The outer ring w1 is a rubber ring with a port and has a certain degree of flexibility. The expansion ring w2 has annular flexibility, and the pressure ball w4 has Predominantly, there are seven engaging blocks w3, which are uniformly arranged in a ring shape, and respectively correspond to the through-holes on the outer ring w1, and the pressing ball w4 acts on the expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com