Water flushing fully degradable recycled non-woven fabric

A non-woven fabric, fully degradable technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of large amount of recycled viscose fiber, blockage of sewer pipes, and inability to disperse instantly, so as to reduce consumption, reduce consumption, The effect of balanced design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

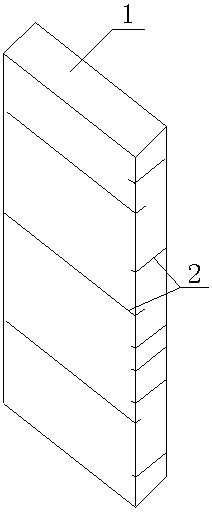

[0012] Embodiment 1: with reference to attached figure 1 . A water flushing fully degradable recycled non-woven fabric, which is made of 1%-14% regenerated cellulose fiber and 99%-86% wood pulp fiber by weight, and has a weight of 30g-120g / ㎡ Fully degradable recycled non-woven fabric. Regenerated cellulose fiber refers to viscose fiber, tencel fiber, bamboo fiber, etc., and its structure is flat fiber structure, sawtooth fiber structure, round fiber structure, oval fiber structure and other irregular structures.

[0013] The length of the regenerated cellulose fiber is 5.1-19.9mm, among the regenerated cellulose fibers, the fiber length is greater than or equal to 10.0mm and less than or equal to 19.9mm, accounting for 71-89%, and the fiber length is greater than or equal to 5.1mm and less than or equal to 9 . 9mm accounts for 11-29%.

[0014] Wood pulp fiber length 1.5-6.0mm, 99%-85% of the wood pulp fibers have a fiber length greater than or equal to 1.5mm and less than o...

Embodiment 2

[0015] Embodiment 2: On the basis of embodiment 1, there are cuts on the regenerated cellulose fiber surface of flat fiber structure, sawtooth fiber structure, round fiber structure, ellipse fiber structure and other irregular structures, and its cut is to throw and cut forming .

Embodiment 3

[0016] Example 3: On the basis of Example 1, 1% regenerated cellulose fiber and 99% wood pulp fiber are made into a water flushing dispersion fully degradable regenerated non-woven fabric with a gram weight of 30 g-120 g / ㎡ and wood pulp fiber The length of the regenerated cellulose fiber is greater than or equal to 10.0mm and less than or equal to 19.9mm, accounting for 90-80% of the length is greater than 3.5mm and less than or equal to 6.0mm, accounting for 71-89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com