Low-density ethylene propylene diene monomer extruded sponge material and preparation method thereof

A technology of EPDM rubber and low density, which is applied in the field of low-density EPDM rubber extruded sponge material and its preparation, which can solve the problems of high specific gravity, unsuitability, and high viscosity of EPDM sponge, and achieve stiffness Good, prevent sudden decomposition, fast vulcanization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

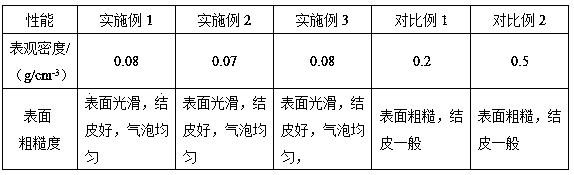

Examples

Embodiment 1

[0037] A low-density EPDM extruded sponge material, prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 30 parts of carbon black, 30 parts of paraffin oil, 150 parts of inorganic filler, and 1.5 parts of sulfur , 30 parts of azodicarbonamide, 5 parts of vulcanization accelerator, 5 parts of active zinc oxide, 2 parts of stearic acid, and 5 parts of calcium oxide.

[0038] Among them, the ethylene content of EPDM rubber is 40-55%, the Mooney viscosity is 60-73, and the third monomer ENB content is 7-10%.

[0039] The inorganic filler is a mixture of talcum powder, calcium carbonate and kaolin, and the mass ratio of the three is 4:1:1.

[0040] The vulcanization accelerator is 1.2 parts of 2-mercaptobenzothiazole, 1 part of dithiodibenzothiazole, 0.5 part of zinc dibutyldithiocarbamate, 0.5 part of zinc dimethyldithiocarbamate, 0.3 part of bispentamethylenethiuram sulfide, 0.2 part of tellurium diethyldithiocarbamate, 0.3 part of diphenylguan...

Embodiment 2

[0047] A low-density EPDM rubber extruded sponge material, prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 30 parts of carbon black, 30 parts of paraffin oil, 100 parts of inorganic filler, and 1.5 parts of sulfur , 30 parts of azodicarbonamide, 5 parts of vulcanization accelerator, 5 parts of active zinc oxide, 2 parts of stearic acid, and 5 parts of calcium oxide.

[0048] The ethylene content of EPDM rubber is 40-55%, the Mooney viscosity (ML(1+4)125°C) is 60-73, and the third monomer ENB content is 7-10%.

[0049]The inorganic filler is a mixture of talcum powder, calcium carbonate and kaolin, and the mass ratio of the three is 4:1:1.

[0050] The vulcanization accelerator is 1.2 parts of 2-mercaptobenzothiazole, 1 part of dithiodibenzothiazole, 0.5 part of zinc dibutyldithiocarbamate, 0.5 part of zinc dimethyldithiocarbamate, 0.3 part of bispentamethylenethiuram sulfide, 0.2 part of tellurium diethyldithiocarbamate, 0.3 part of dip...

Embodiment 3

[0057] A low-density EPDM rubber extruded sponge material, prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 30 parts of carbon black, 30 parts of paraffin oil, 170 parts of inorganic filler, and 1.5 parts of sulfur , 30 parts of azodicarbonamide, 7 parts of vulcanization accelerator, 7 parts of active zinc oxide, 2 parts of stearic acid, and 5 parts of calcium oxide.

[0058] The ethylene content of EPDM rubber is 40-55%, the Mooney viscosity (ML(1+4)125°C) is 60-73, and the third monomer ENB content is 7-10%.

[0059] The inorganic filler is a mixture of talcum powder, calcium carbonate and kaolin, and the mass ratio of the three is 4:1:1.

[0060] The vulcanization accelerator is 1.2 parts of 2-mercaptobenzothiazole, 1 part of dithiodibenzothiazole, 1 part of zinc dibutyldithiocarbamate, 1 part of zinc dimethyldithiocarbamate, 0.5 parts of bispentamethylenethiuram sulfide, 0.5 parts of tellurium diethyldithiocarbamate, 0.3 parts of dip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com